Food-grade bamboo vinegar and preparation method thereof

A technology of food-grade bamboo vinegar, which is applied in the field of food-grade bamboo vinegar and its preparation, can solve the problem of high production cost and achieve the effect of pure product and good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

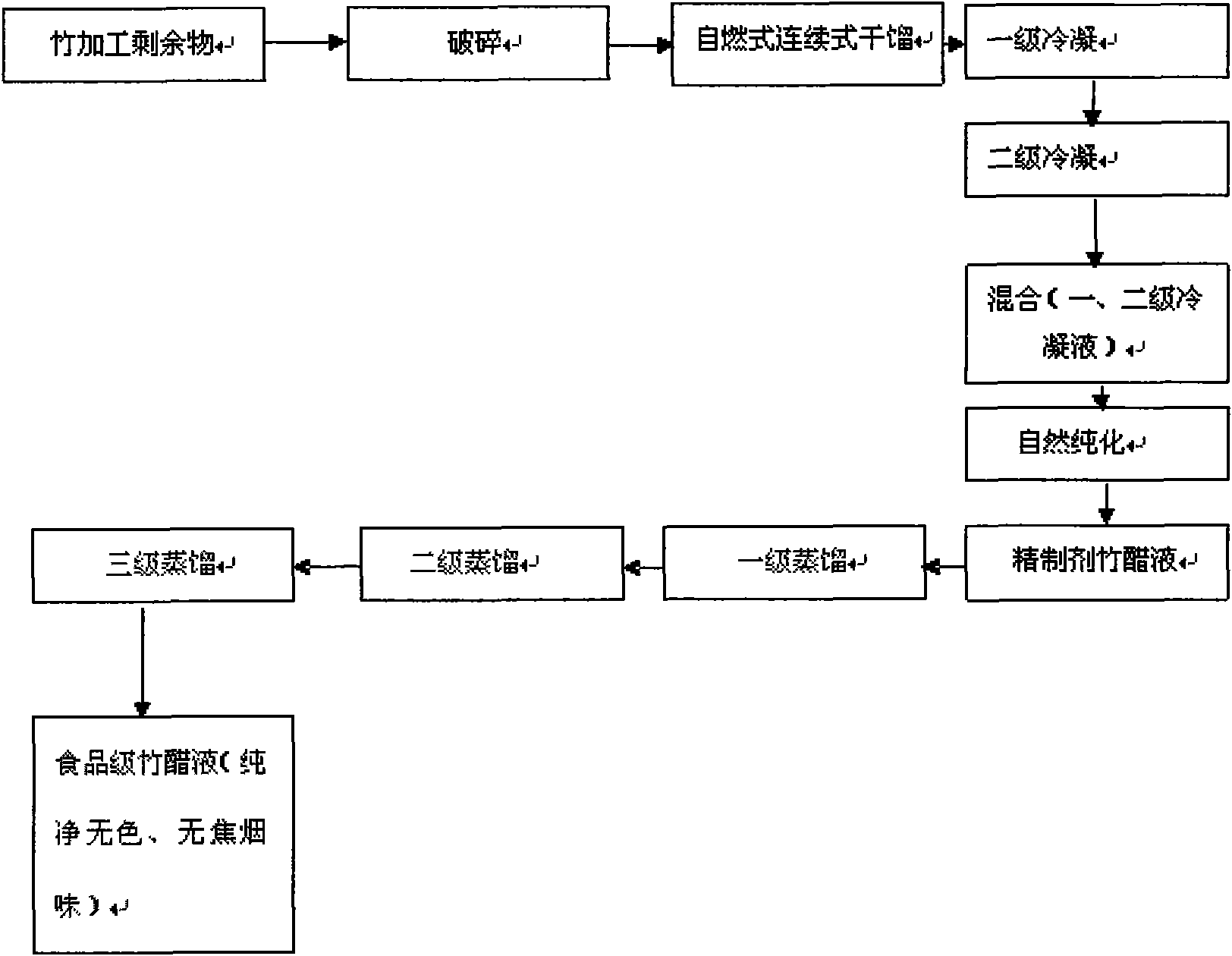

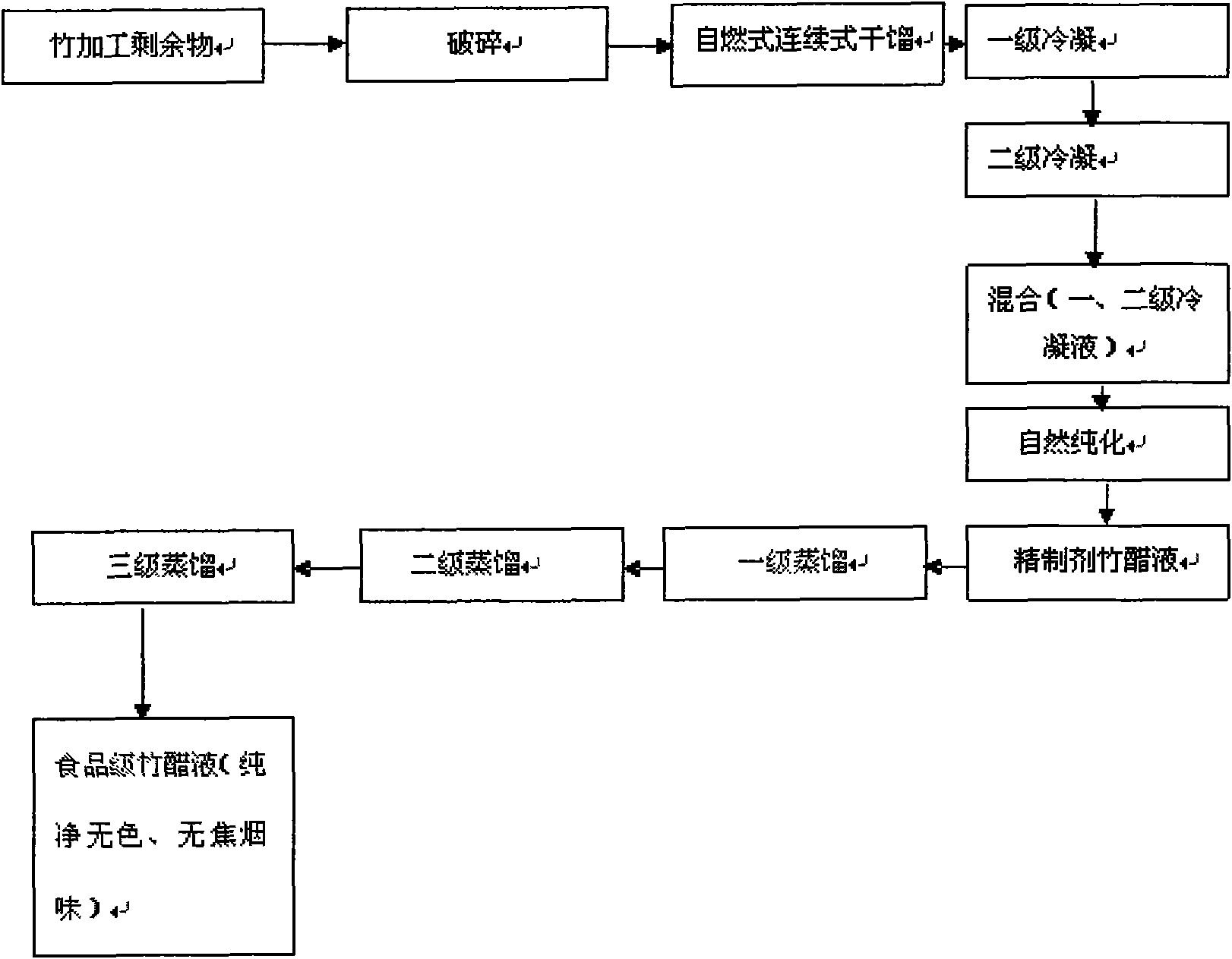

Method used

Image

Examples

Embodiment 1

[0038] After collecting bamboo that has grown for 3-5 years or unpolluted bamboo processing residues, use a disc-type bamboo crusher (for extrusion, cutting) to slice it, and the size of the bamboo slices is 4-6cm×4-6cm , and then placed in the bamboo and wood vinegar extraction and purification equipment of Korea Juyu Wood Vinegar Industry (2005-10 type), the temperature is controlled in the range of 200°C-500°C, and the self-ignition continuous dry distillation is carried out, and the primary and secondary condensation are carried out. The temperature is controlled in the range of 80°C-120°C to obtain bamboo vinegar liquid and the temperature is controlled in the range of 100°C-120°C to obtain bamboo vinegar liquid, and the primary and secondary condensate are mixed in the mixing tank under normal temperature and pressure. Standing and purifying for 180 days in a natural state, the refined bamboo vinegar liquid can be obtained.

[0039] The resulting refined bamboo vinegar i...

Embodiment 2

[0041] After collecting bamboo that has grown for 3-5 years or unpolluted bamboo processing residues, use a disc-type bamboo crusher (for extrusion, cutting) to slice it, and the size of the bamboo slices is 4-6cm×4-6cm , and then placed in the bamboo and wood vinegar extraction and purification equipment of Korea Juyu Wood Vinegar Industry (2005-10 type), the temperature is controlled in the range of 200°C-500°C, and the self-ignition continuous dry distillation is carried out, and the primary and secondary condensation are carried out. The temperature is controlled in the range of 80°C-120°C to obtain bamboo vinegar liquid and the temperature is controlled in the range of 100°C-120°C to obtain bamboo vinegar liquid, and the primary and secondary condensate are mixed in the mixing tank under normal temperature and pressure. Standing and purifying for 180 days in a natural state, the refined bamboo vinegar liquid can be obtained.

[0042] Place the bamboo vinegar solution of p...

Embodiment 3

[0044] Bamboo Vinegar Nursing Cream: Take the bamboo vinegar liquid obtained in Example 1 or Example 2 as the main component, with purified water, glycerin, herbal essence, mineral oil, castor oil, isopropyl myristate and aloe vera extract , green tea extract, olive extract, beeswax and spices, etc. Bamboo vinegar care cream can deeply clean the skin, exfoliate, inhibit bacteria and deodorize, lock water and moisturize, and make the skin radiant and beautiful.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com