Anti-settling aid, and preparation method and application thereof

An anti-settling and additive technology, applied in the field of materials, can solve problems such as unfavorable dispersion of cement and mineral admixtures, low steric hindrance, and reduced viscosity of thickeners, achieving obvious anti-settling effect, lowering production costs, and reducing The effect of subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

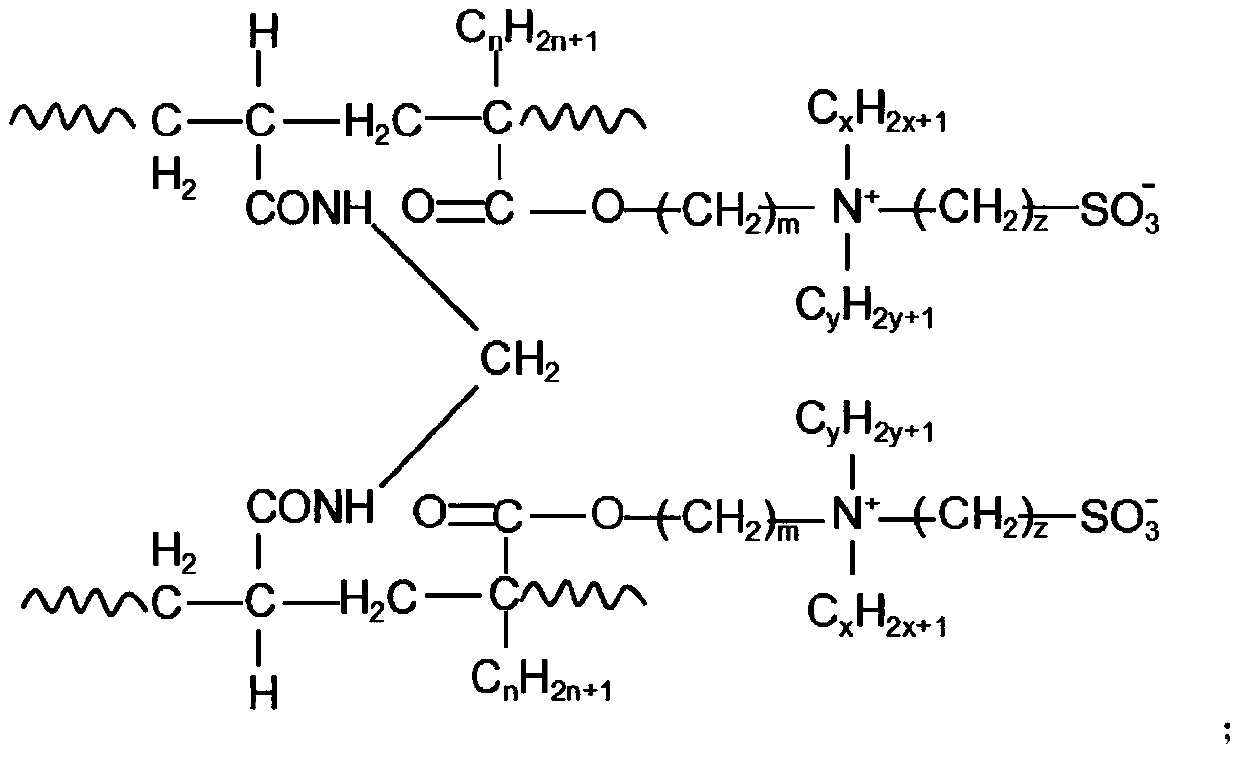

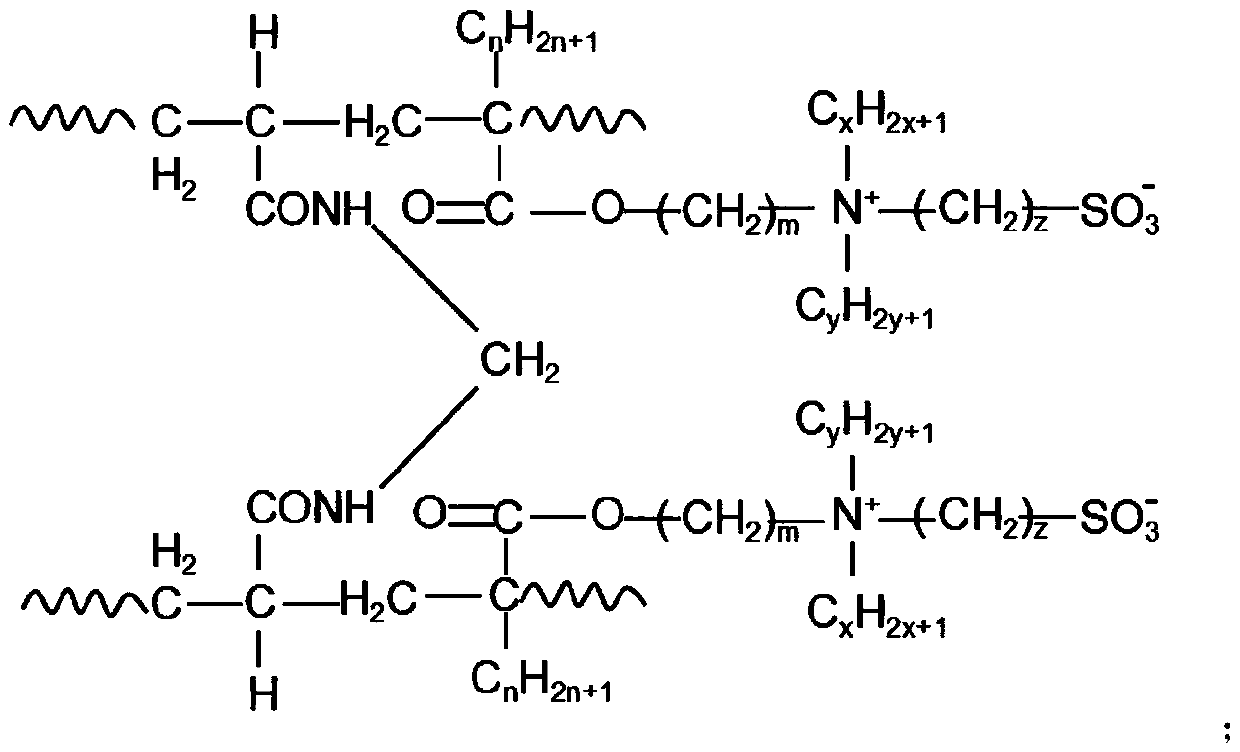

Method used

Image

Examples

Embodiment 1

[0042] A kind of preparation of anti-sedimentation aid, comprises the following steps:

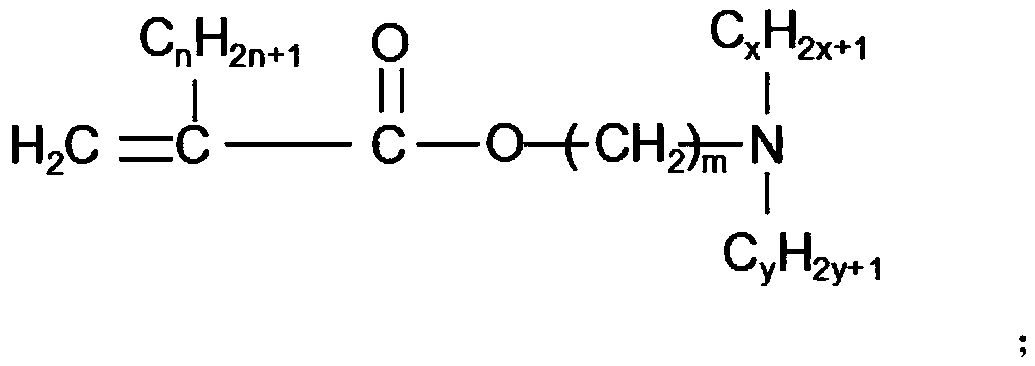

[0043] (1) Polymerization reaction

[0044] Access to N 2 Rinse the three-necked flask, then add a certain amount of deionized water, 0.1mol ethacryloyloxymethyldiethylamine and 0.0005mol hydroquinone, stir to dissolve, gradually raise the temperature to 65°C, stir at constant temperature for 10min, drop by drop Add a mixture of 0.1mol 1,4-butyl sultone and 15ml of acetone, dropwise for 2h, after the dropwise addition is completed, react at a constant temperature for 10h, then cool the reactant to terminate the reaction, filter and wash repeatedly ℃ vacuum drying to obtain the functional monomer ethacryloyloxymethyl diethylaminobutanesulfonate;

[0045] (2) Copolymerization reaction

[0046] First add a certain amount of 0.5mol / L sodium chloride solution to the polymerization bottle, then add 0.3mol acrylamide and 0.001mol ethacryloyloxymethyldiethylaminobutanesulfonate monosodium chlor...

Embodiment 2

[0051] The difference between this example and example 1 is: after the copolymerization reaction for 4 hours, acetone was used to terminate the reaction.

[0052] The effect of the anti-sedimentation additive prepared in this example on the anti-sedimentation of cement and mineral admixtures was tested when the amount of the anti-sedimentation additive prepared in this example was 1 wt% in the wet grinding concrete waste slurry. See Table 1 for specific results.

Embodiment 3

[0054] The difference between this example and example 1 is: after the copolymerization reaction for 12 hours, acetone was used to terminate the reaction.

[0055] The effect of the anti-sedimentation additive prepared in this example on the anti-sedimentation of cement and mineral admixtures was tested when the amount of the anti-sedimentation additive prepared in this example was 1 wt% in the wet grinding concrete waste slurry. See Table 1 for specific results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com