Composite type activated carbon and application thereof in purifying tacrolimus

A technology of tacrolimus and activated carbon, which is applied to composite activated carbon and its preparation and application in purifying tacrolimus, can solve the problems of large amount of elution solvent, low purity and yield, and difficult separation, etc. , to achieve the effect of being conducive to green production, simple operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

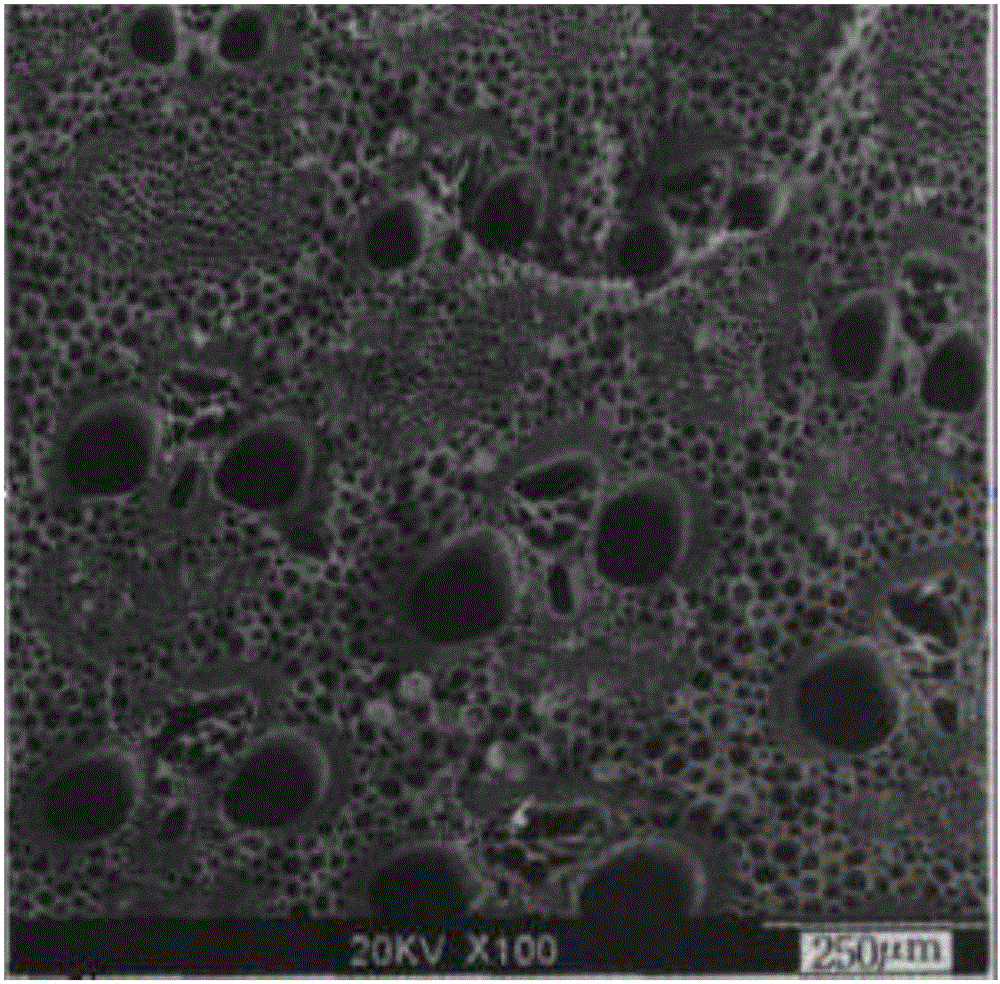

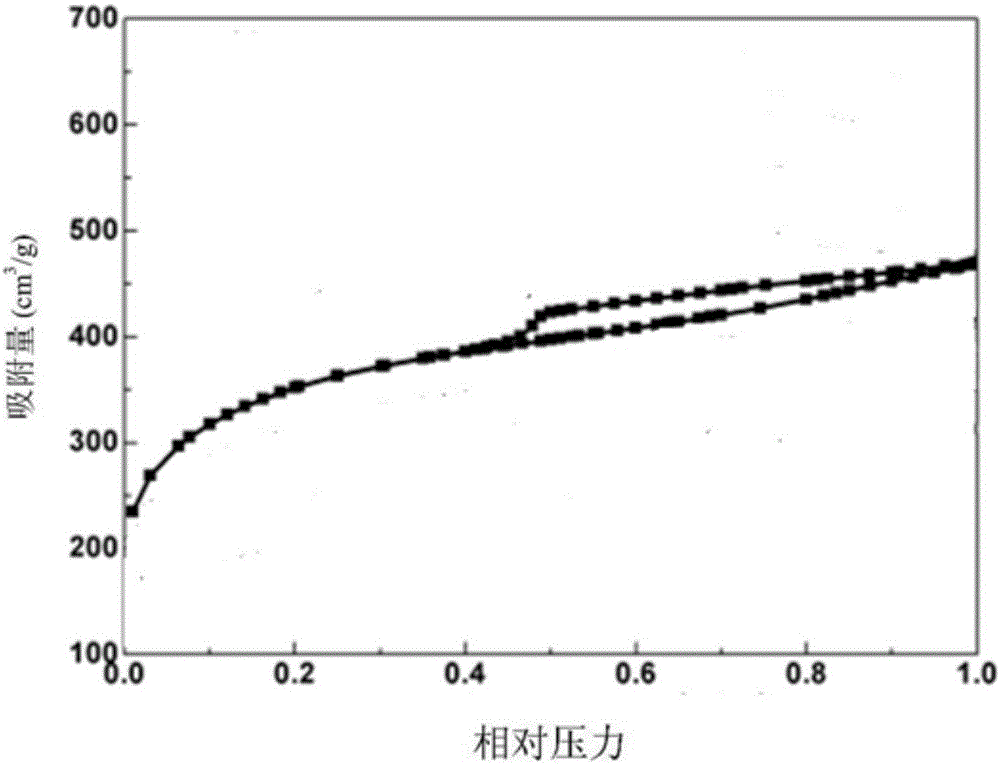

[0058] Preparation method of composite activated carbon

[0059] 1) Screening and drying of sawdust

[0060] The crushed sawdust with a moisture content of 40% is sent to the vibrating screen by the bucket elevator to be screened to obtain sawdust with a particle size of 6-40 mesh, which is transported to the cyclone separator by the blower, and the separated sawdust falls into the storage bin.

[0061] The wood chips are quantitatively and continuously dropped into the screw feeder from the disc feeder under the silo, and then fed into the hot air pipe, and the wood chips are air-dried in hot air at 120-150 °C, and the hot air flow rate is 8 m / s; after drying The wood chips have a moisture content of 18%.

[0062] 2) Prepare a potassium hydroxide aqueous solution with a concentration of 70%.

[0063] 3) Kneading

[0064] Kneading the dried sawdust in step 1) with the aqueous potassium hydroxide solution in step 2) under stirring; the weight ratio of the sawdust to the aque...

Embodiment 2

[0072] Take 1000g of fermentation broth bacteria residue, extract with 7L of ethanol to obtain about 60g of concentrated solution, dilute to 500ml with ethyl acetate, add 500ml of 2% NaOH aqueous solution, keep at 50°C for 3 hours and then separate to obtain the ethyl acetate phase; Add 500 ml of 1% NaOH aqueous solution to the ethyl ester phase, stir well and let stand overnight.

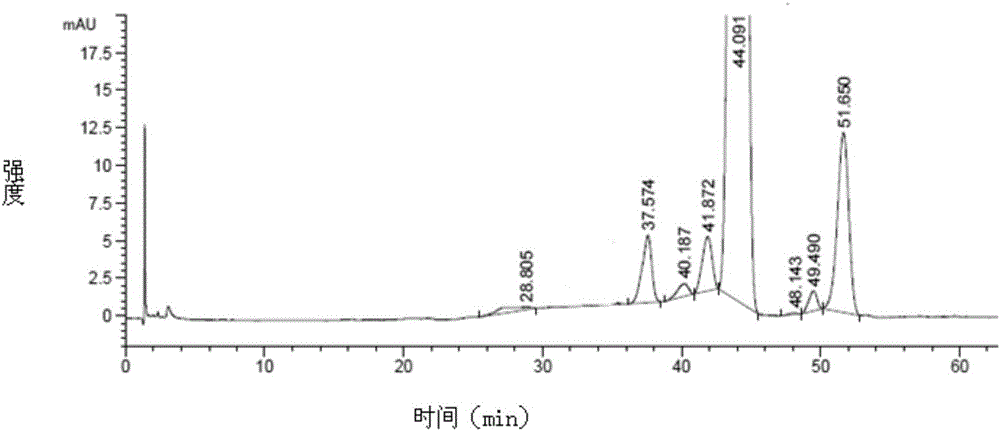

[0073] The next day, the extract was separated, and 12 g of the composite activated carbon prepared according to Example 1 was added, stirred at room temperature for 1 hour, filtered, rinsed with an appropriate amount of ethyl acetate, and 700 ml of filtrate was obtained.

[0074] Concentrate the filtrate to about 40g, add 30ml of ethyl acetate to dissolve, keep stirring for 1h, add 40ml of purified water and 160ml of n-hexane in batches within 1h, continue stirring for 1h, and let stand overnight.

[0075] Filter the crystallization solution, wash with 40ml of n-hexane and 40ml of pure water respe...

Embodiment 3

[0077] 1) Take 2500g of fermentation broth bacteria residue, extract with 20L of acetone to obtain about 150g of concentrated solution, dilute to 1800ml with ethyl formate, add 600ml of 1% Na 2 CO 3 Aqueous solution, separated at 50°C for 3 hours.

[0078] 2) After layering, add 600ml of 0.5% Na to the ethyl formate phase 2 CO 3 , stir well and let stand overnight.

[0079] 3) The next day, the extract was separated, and 40 g of the composite activated carbon prepared in Example 1 was added, stirred at room temperature for 1 h, filtered, and rinsed with an appropriate amount of ethyl formate to obtain the filtrate.

[0080] 4) Concentrate the filtrate to about 100 g, add 100 ml of acetone to dissolve, stir at room temperature for 1 h, add 50 ml of purified water and 500 ml of n-heptane in batches within 0.5 h, continue stirring for 1 h, and let stand overnight.

[0081] 5) Filter the crystallization solution, wash with 100ml of n-heptane and 100ml of pure water respectivel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com