Acid and alkaline resistant micro-nano aluminum powder/porous carbon composite material and synthesis method thereof

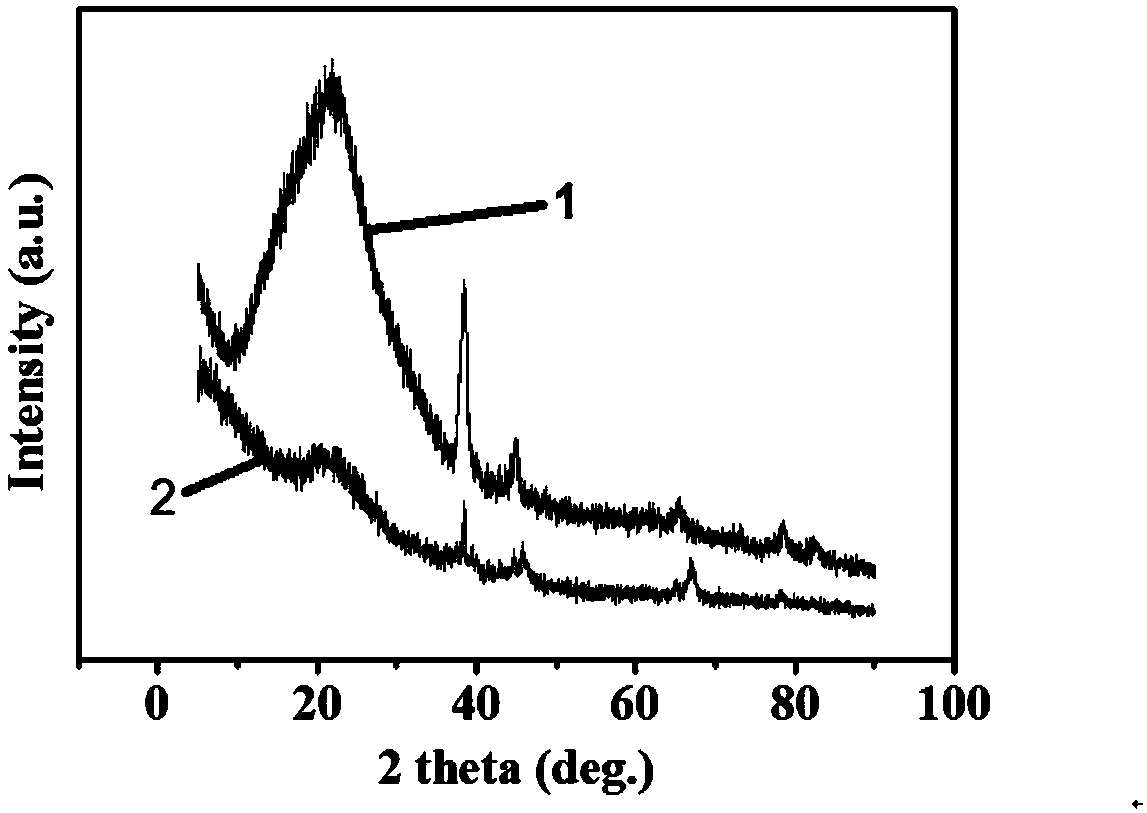

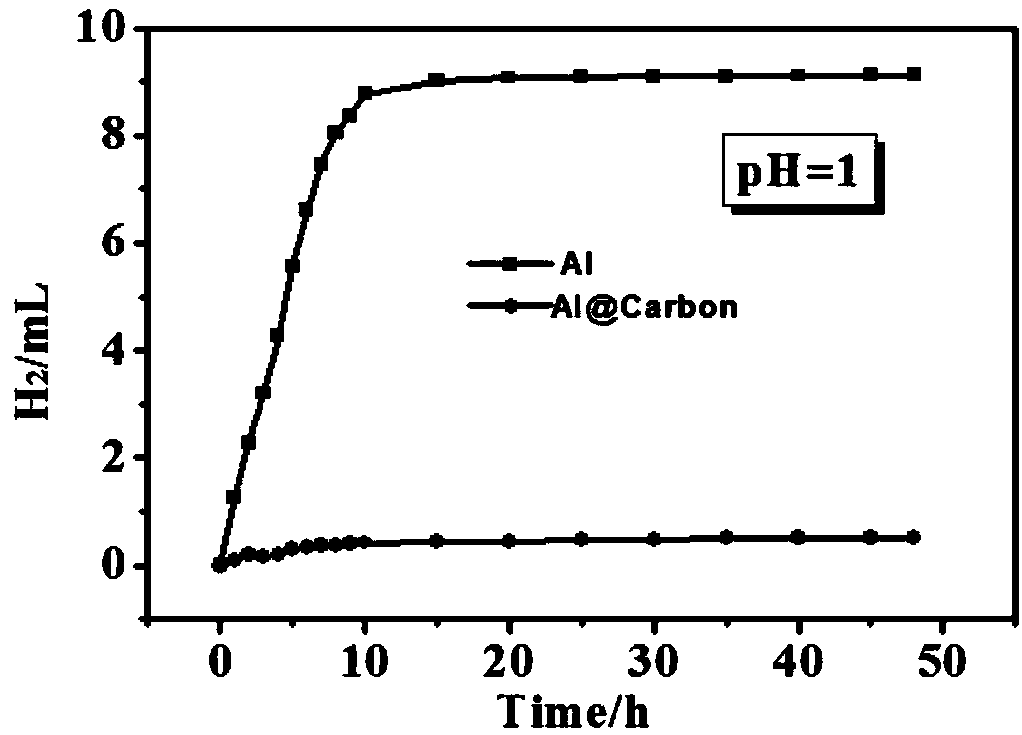

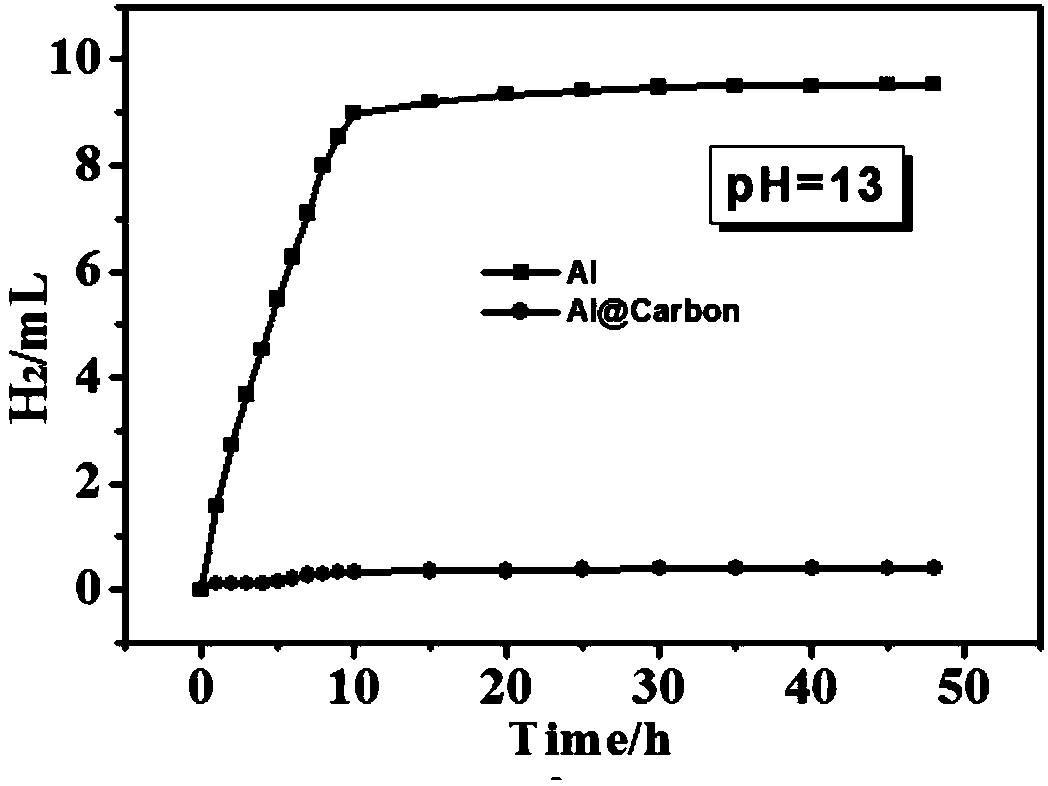

A technology of composite materials and synthesis methods, which is applied in the field of acid and alkali-resistant micro-nano aluminum powder/porous carbon composite materials and their synthesis, can solve the problems of difficulty in controlling the size of core-shell particles, difficulty in controlling the shape of products, and small production scale. Achieve the effect of smooth and regular surface, good crystallization and easy control of particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] An acid and alkali resistant micro-nano aluminum powder / porous carbon composite material, prepared from the following components in weight (kg):

[0041] Aluminum powder 30, phenolic resin 25, ethyl acetate 25, propylene glycol methyl ether acetate 12, carboxymethyl cellulose 6; BYK-3001.5; KH-550 0.3; polyethylene wax 0.2;

[0042] The preparation method includes the following steps:

[0043] (1) First design a composite solvent system, put ethyl acetate and propylene glycol methyl ether acetate into a stirring tank and stir fully, start to adjust the speed to 2000r / min, and control the temperature at 50℃. After the dispersion is even, the stirring speed As low as 500r / min, add carboxymethylcellulose and KH-550 dropwise in sequence under stirring conditions, add polyethylene wax and BYK-300 after cooling to 30°C, and stir for 20 minutes;

[0044] (2) Then add aluminum powder and phenolic resin to the above solvent system in sequence, and ultrasonic dispersion treatment for 45 ...

Embodiment 2

[0047] An acid and alkali resistant aluminum powder / porous carbon composite material, prepared from the following components in weight (kg):

[0048] Aluminum powder 35, epoxy resin 27, acetone 20, palm oil 10, polyacrylamide 5; BYK-331 2; KH-560 0.5; organic bentonite 0.5;

[0049] The preparation method includes the following steps:

[0050] (1) First design a composite solvent system, put the acetone and palm oil into the stirring tank and fully stir, start to adjust the speed 2500r / min, the temperature is controlled at 55℃, after the dispersion is uniform, reduce the stirring speed to 800r / min, add polyacrylamide and KH-560 dropwise in sequence under stirring conditions, add organic bentonite and BYK-331 after cooling to 35℃, and stir for 25 minutes;

[0051] (2) Then add aluminum powder and epoxy resin to the above solvent system in sequence, ultrasonic dispersion treatment for 50 minutes, drying at 90°C for 1.5 hours to obtain aluminum-based precursor;

[0052] (3) Finally, the ...

Embodiment 3

[0054] An acid and alkali resistant micro-nano aluminum powder / porous carbon composite material, prepared from the following components in weight (kg):

[0055] Aluminum powder 40, glucose 20, ethanol 25, Taikoo oil 8, polyethylene glycol 4; 201 methyl silicone oil 2; YB-401 0.7; polyglycerol ricinol ester 0.3;

[0056] (1) First design a composite solvent system, put ethanol and Taikoo oil into the stirring tank and stir thoroughly, start to adjust the speed to 3000r / min, and control the temperature at 60℃. After the dispersion is uniform, reduce the stirring speed to 1000r / min, add polyethylene glycol and YB-401 dropwise in sequence under stirring conditions, add polyglycerol ricinol ester and methyl silicone oil after cooling to 40°C, and stir for 30 minutes;

[0057] (2) Then add aluminum powder and glucose to the above-mentioned composite solvent system in sequence, and ultrasonic dispersion treatment for 60 minutes. Dry at 100°C for 2 hours to obtain an aluminum-based precurs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com