Acrylic resin retanning agent and preparation method thereof

A technology of acrylic resin and retanning agent, which is applied in animal husbandry, chemical treatment and application of small raw hide/large raw hide/leather skin/fur, and can solve the problem of high synthesis temperature, unsuitable temperature control, and affecting the absorption of dyes and fats and other problems, to achieve the effect of stable reaction, favorable absorption, and improved dyeing and fatliquoring effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

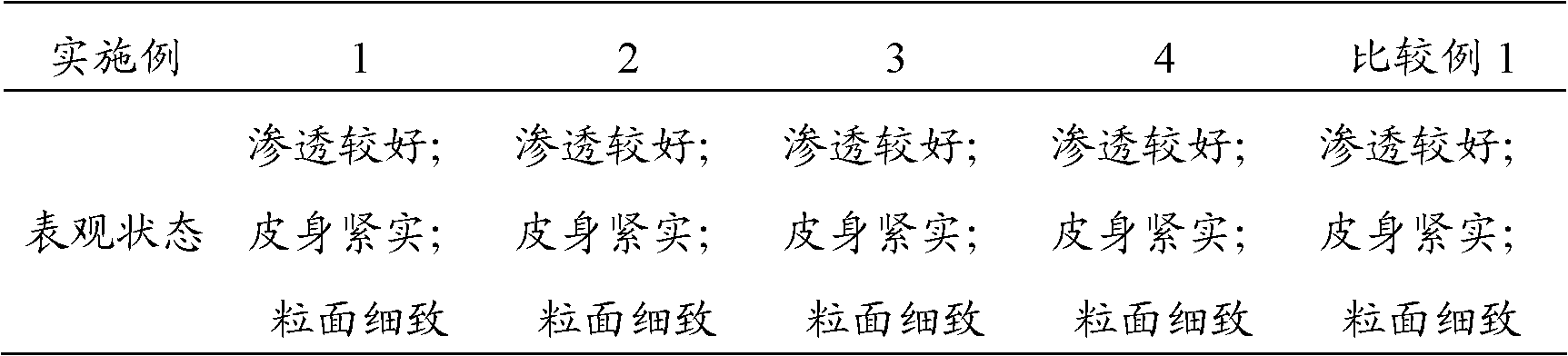

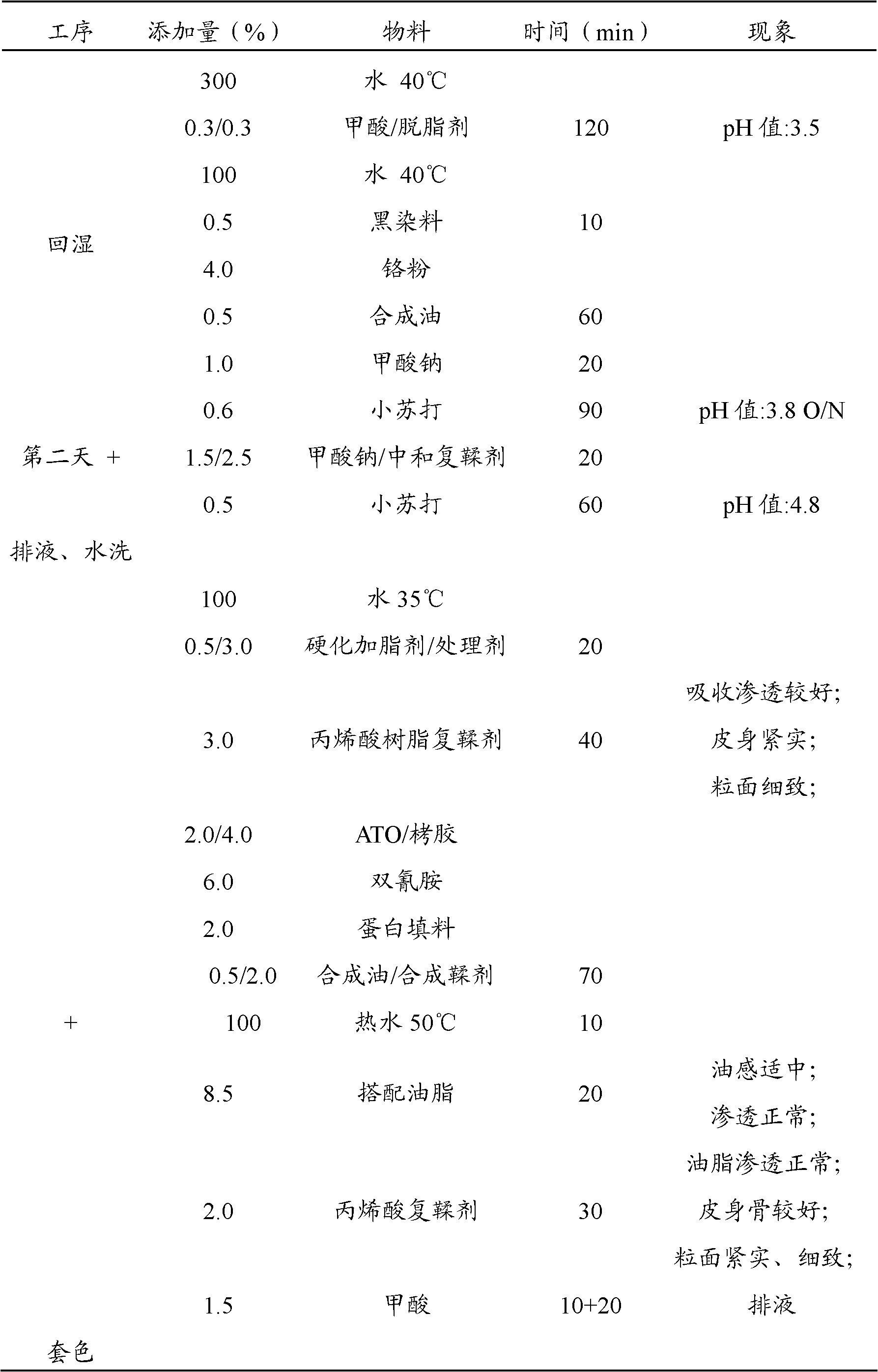

Examples

preparation example Construction

[0046] The present invention also provides a kind of preparation method of the described acrylic resin retanning agent of above-mentioned technical scheme, comprises the following steps:

[0047] a) mixing acrylic acid or methacrylic acid, acyloxyethyltrimethylammonium methacrylate, ethyl acetoacetoxymethacrylate, chain regulator, catalyst and water to obtain a mixture;

[0048] b) The mixture obtained in step a) is mixed with the first initiator to carry out a polymerization reaction for 90 minutes to 120 minutes; the first initiator is peroxide or persulfate;

[0049] c) adding a second initiator to the reaction product obtained in step b) to continue the reaction; the second initiator is azobisisobutylamidine hydrochloride;

[0050] d) adding alkali and water to the reaction product obtained in step c) to obtain an acrylic resin retanning agent.

[0051] In the present invention, firstly, acrylic acid or methacrylic acid, methacrylic acid acyloxyethyl trimethyl ammonium ch...

Embodiment 1

[0069] Adding 240kg water, 640kg mass concentration in the premix tank is 78% methacrylic acid acyloxyethyltrimethylammonium chloride (DMC), 480kg acrylic acid, 80kg acetoacetoxy ethyl methacrylate (AAEM), 8kg Mercaptoethanol and 5.6kg mass concentration are 1% ferrous sulfate solution, after stirring for 20 minutes, the mixture is obtained;

[0070] Adding 105kg of mass concentration to the head tank is a 30% hydrogen peroxide solution, adding 640kg of deionized water to the reactor, and adding the mixture and the hydrogen peroxide solution dropwise to the reactor after the temperature is raised to 35° C. The dropping time is controlled at 1.5h~2h; after the dropping, the temperature rises naturally to 70°C~80°C, reacts at this temperature for 30min, then heats up to 80°C~85°C, stirs for 1h, and then slowly adds 36kg mass concentration It is a 10% azobisisobutylamidine hydrochloride (V50) solution, and the addition time is 20min to 30min. After the addition of V50 is complete...

Embodiment 2

[0072] Add 240kg water, 720kg mass concentration in the premix tank and be 78% methacrylic acid acyloxyethyl trimethyl ammonium chloride (DMC), 510kg acrylic acid, 64kg acetoacetoxy ethyl methacrylate (AAEM), 16kg Mercaptopropionic acid and 5.6kg mass concentration are 1% ferrous sulfate solution, after stirring for 20 minutes, the mixture is obtained;

[0073]Adding 112kg of mass concentration to the header tank is a 30% hydrogen peroxide solution, adding 640kg of deionized water to the reactor, and adding the mixture and the hydrogen peroxide solution dropwise to the reactor after the temperature is raised to 30° C. The dropping time is controlled at 1.5h~2h; after the dropping, the temperature rises naturally to 70°C~80°C, reacts at this temperature for 30min, then heats up to 80°C~85°C, stirs for 1h, and then slowly adds 38kg mass concentration It is a 10% azobisisobutylamidine hydrochloride (V50) solution, and the addition time is 20min to 30min. After the addition of V50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com