Preparation method of ultrafine vanadium dioxide powder

A technology of ultra-fine powder and vanadium dioxide, which is applied in the direction of vanadium oxide, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of increasing production costs and easy introduction of impurities, and achieve low cost and broad Market prospect, wide application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

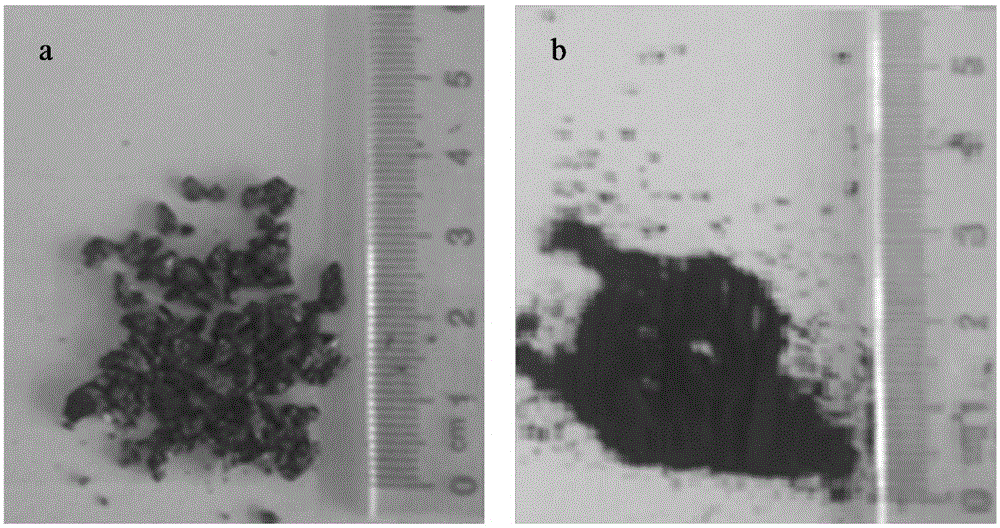

[0033] A preparation method of vanadium dioxide ultrafine powder includes the following steps:

[0034] Step 1: Preparation of product precursor

[0035] Vanadium sulfate trihydrate VOSO 4 ·3H 2 O was dissolved in distilled water, and then an alkaline solution was added, and the pH of the solution was slowly adjusted to 6-7 to obtain an off-white suspension; the suspension was filtered and cleaned to obtain an amorphous product precursor; the product precursor was put into vacuum Drying is carried out in a drying oven, the drying temperature is 60-80°C, and the drying time is 24-48h to obtain a dry, loose, non-caking precursor powder, and the obtained precursor powder has a mesh number greater than 1000 mesh. The soluble hexavalent tungsten compound used is one or more of sodium tungstate, ammonium tungstate or tungstic acid, and the alkaline solution used is one of sodium hydroxide, sodium carbonate, sodium bicarbonate or aqueous ammonia Or multiple.

[0036] Step 2: Preparation o...

Embodiment 1

[0045] A preparation method of vanadium dioxide ultrafine powder includes the following steps:

[0046] Step 1: Preparation of product precursor

[0047] Vanadium sulfate trihydrate VOSO 4 ·3H 2 O is dissolved in distilled water, and 0.01mol / L dilute NaHCO 3 The solution is added dropwise to the continuously stirred VOSO at a rate of 50mL / h with a syringe pump 4 In the solution, control the pH value in the range of 6-7 to obtain an off-white suspension; the suspension is filtered and cleaned to obtain an amorphous product precursor; the product precursor is placed in a vacuum drying oven for drying, and the drying temperature is 80 ℃, the drying time is 24h, to obtain a dry, loose, non-caking precursor powder, and the obtained precursor powder has a mesh number greater than 1000 mesh. The soluble hexavalent tungsten compound used is one or more of sodium tungstate, ammonium tungstate or tungstic acid, and the alkaline solution used is one of sodium hydroxide, sodium carbonate, sodi...

Embodiment 2

[0057] A preparation method of vanadium dioxide ultrafine powder includes the following steps:

[0058] Step 1: Preparation of product precursor

[0059] Vanadium sulfate trihydrate VOSO 4 ·3H 2 O is dissolved in distilled water, and 0.01mol / L dilute NaHCO 3 The solution is added dropwise to the continuously stirred VOSO at a rate of 50mL / h with a syringe pump 4 In the solution, control the pH value in the range of 6-7 to obtain an off-white suspension; filter the suspension to obtain an amorphous product precursor; put the product precursor in a vacuum drying oven for drying, and the drying temperature is 80 ℃, the drying time is 24h, to obtain a dry, loose, non-caking precursor powder, and the obtained precursor powder has a mesh number greater than 1000 mesh. The soluble hexavalent tungsten compound used is one or more of sodium tungstate, ammonium tungstate or tungstic acid, and the alkaline solution used is one of sodium hydroxide, sodium carbonate, sodium bicarbonate or aqueo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com