Transformer framework preventing winding lead wire from crossing

A technology of transformer skeleton and winding leads, which is applied to the parts of transformer/inductor, transformer/inductor coil/winding/connection, electrical components, etc., which can solve the problem of inability to realize fully automatic production of transformers, uncontrollable quality of transformers, and uneven quality unevenness and other problems, to promote green production, avoid direct cross-contact, and ensure consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

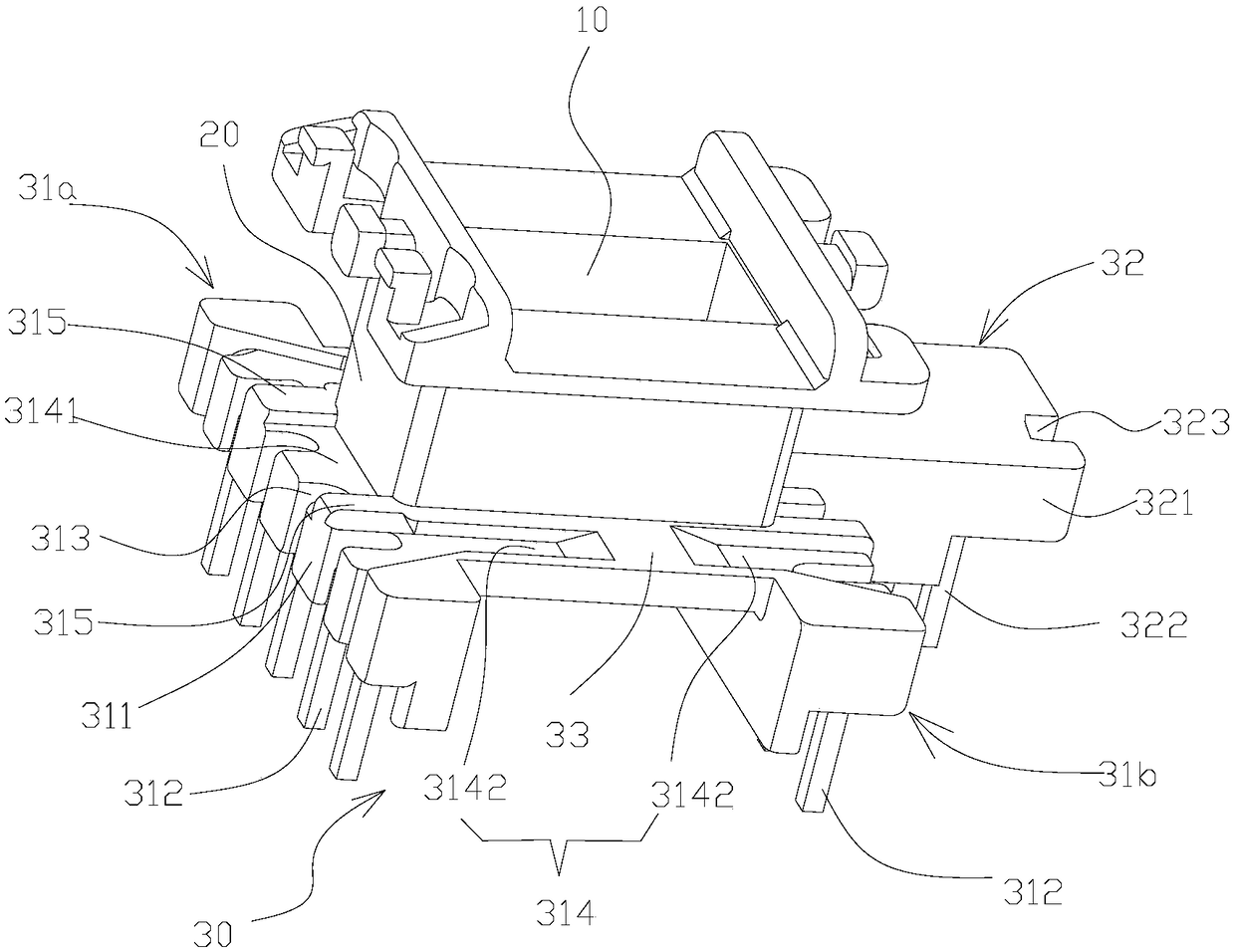

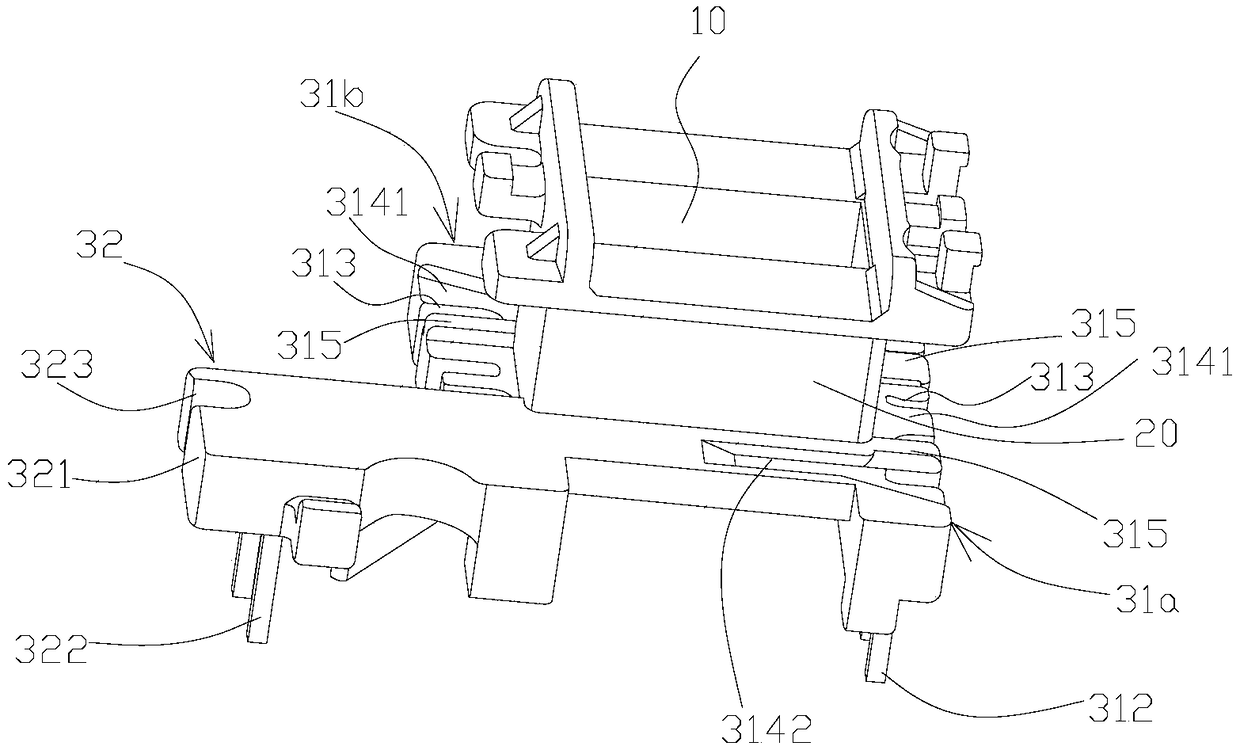

[0030] Such as Figure 1-5 As shown, in this specific embodiment, the transformer bobbin includes a magnetic core slot 10 that runs through longitudinally, an upper layer of the bobbin vertically arranged on the top periphery of the magnetic core slot 10, a winding bobbin 30 vertically arranged on the bottom periphery of the magnetic core slot 10, and the bobbin The upper layer, the winding bobbin 30 and the outer wall of the magnetic core slot 10 form a winding slot 20 for winding the primary coil 40 and the secondary coil 50 ; the secondary coil 50 is wound outside the primary coil 40 . Wherein, the winding bobbin 30 includes a primary bobbin 31 and a secondary bobbin 32; the primary bobbin 31 includes a first primary bobbin 31a and a second primary bobbin 31b, the first primary bobbin 31a is arranged on one side of the magnetic core slot 10, the second The two primary frames 31b and the secondary frame 32 connected to the inner end of the second primary frame 31b and extend...

Embodiment 2

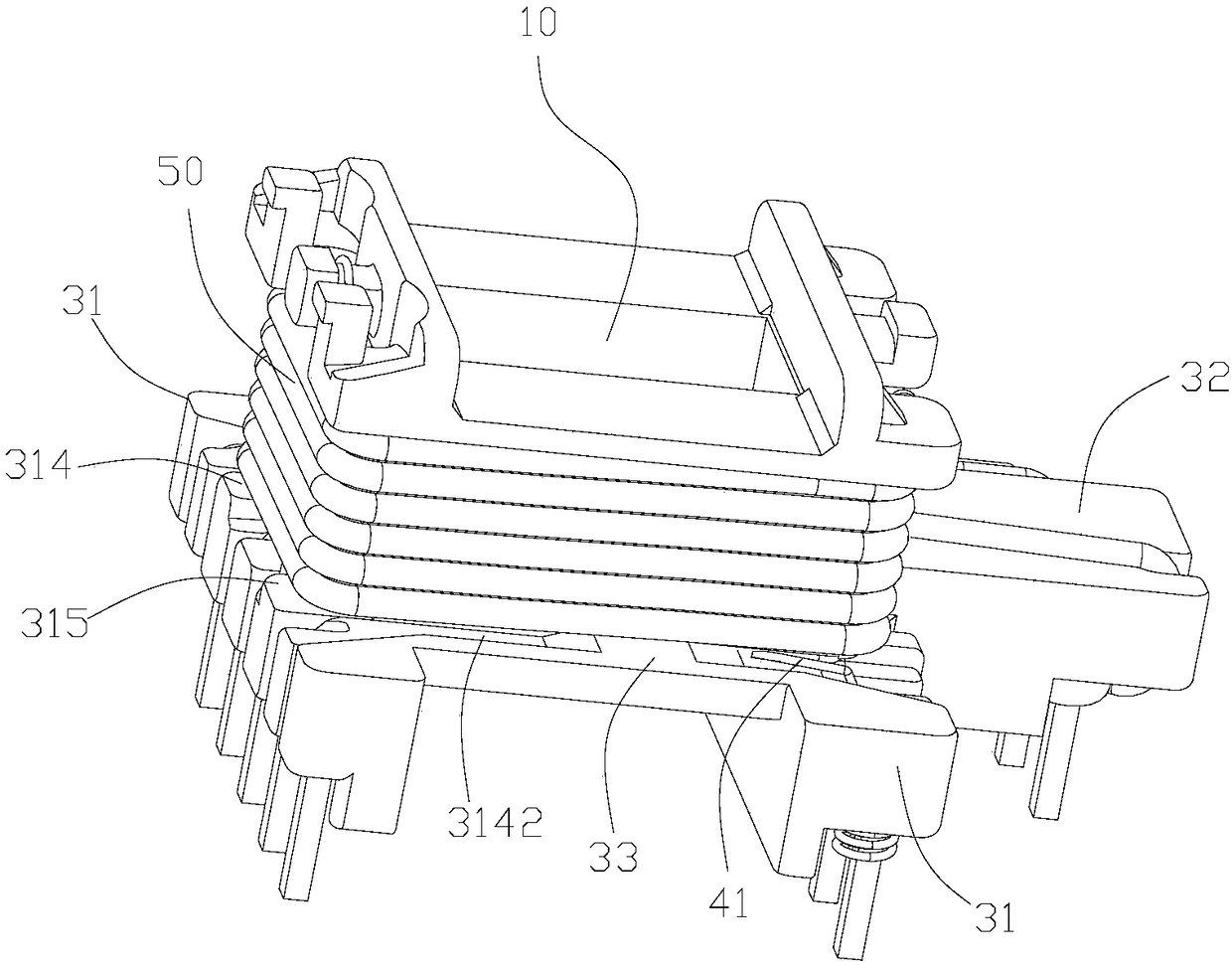

[0038] Such as Figure 6-8 As shown, in this specific embodiment, the transformer skeleton of the invention includes a magnetic core slot 10 that runs through transversely, and the same side at both ends of the magnetic core slot 10 is respectively provided with a winding bobbin 30 in parallel, and the outer wall of the magnetic core slot 10 and the winding bobbin 30 A winding slot 20 for winding the primary coil 40 and the secondary coil 50 is formed. Wherein, the winding frame 30 includes a primary frame 31 and a secondary frame 32, the primary frame 31 includes a first primary frame 31a, a second primary frame 31b, the first primary frame 31a is arranged at one end of the winding groove 20, and the second primary frame 31b and the secondary skeleton 32 connected to the second primary skeleton 31b and extending vertically outward along the length direction of the second primary skeleton 31b form an L-shaped skeleton, and the L-shaped skeleton is arranged at the other end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com