Phase-change composite aerogel and preparation method thereof

A technology of composite airgel and phase change microcapsules, which is applied in the field of phase change composite airgel and its preparation, can solve problems such as being in the blank, and achieve the effects of strong temperature adjustment ability, high energy storage, and shortened preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Dissolve 15 parts of ethyl orthosilicate and 5 parts of methyltrimethoxysilane in a mixed solution of 100 parts of ethanol and 50 parts of water, stir at room temperature until evenly mixed, add an appropriate amount of 5 drops of hydrochloric acid to adjust the pH of the solution To 1-2, hydrolyzed for 20 minutes to form silica sol.

[0022] (2) Add 5 drops of basic catalyst to adjust the pH value of the silica sol to 7-9, so that the sol moderately gels to a certain viscosity. Add 5 parts of phase-change microcapsules and 1 part of quartz fiber, stir at room temperature for 20 minutes to stand still, pour the mixed sol into the mold and let it stand to obtain a wet gel with a certain strength, take the wet gel out of the mold, soak in absolute ethanol Aging in solution for 24h. Finally, the phase-change microcapsule composite silica airgel was obtained by drying under normal pressure at 40°C for 24 hours.

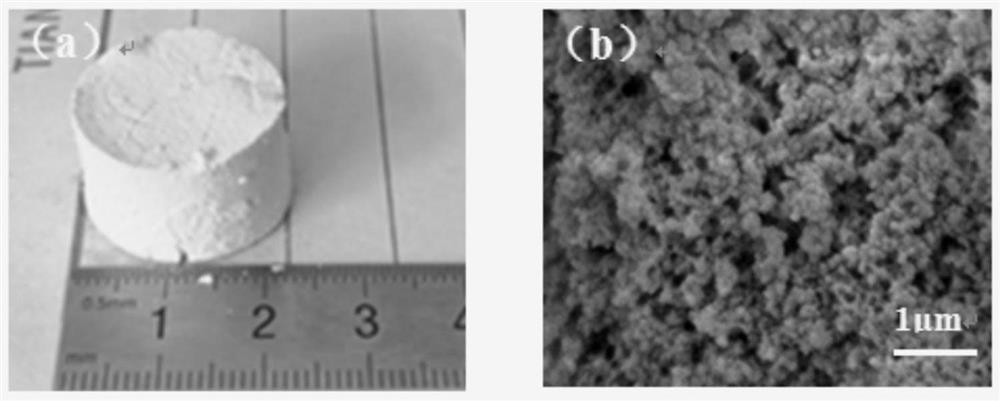

[0023] Such as figure 1 As shown, a is a macroscopic p...

Embodiment 2

[0027] (1) Dissolve 15 parts of ethyl orthosilicate and 5 parts of methyltrimethoxysilane in a mixed solution of 120 parts of ethanol and 30 parts of water, stir at room temperature until evenly mixed, add an appropriate amount of 5 drops of hydrochloric acid to adjust the pH of the solution To 1-3, hydrolyzed for 40 minutes to form silica sol.

[0028] (2) Add 5 drops of basic catalyst to adjust the pH value of the silica sol to 7-10, so that the sol moderately gels to a certain viscosity. Add 10 parts of phase-change microcapsules and 1 part of quartz fiber, stir at room temperature for 20 minutes to stand still, pour the mixed sol into the mold and let it stand to obtain a wet gel with a certain strength, take the wet gel out of the mold, soak in absolute ethanol Aging in solution for 10h. Finally, the phase-change microcapsule composite silica airgel was obtained by drying under normal pressure at 25° C. for 30 h.

Embodiment 3

[0030](1) Dissolve 10 parts of ethyl orthosilicate and 10 parts of methyltrimethoxysilane in a mixed solution of 100 parts of ethanol and 50 parts of water, stir at room temperature until evenly mixed, add an appropriate amount of 5 drops of hydrochloric acid to adjust the pH of the solution To 2-3, hydrolyzed for 20 minutes to form silica sol.

[0031] (2) Add 5 drops of basic catalyst to adjust the pH value of the silica sol to 8-10, so that the sol moderately gels to a certain viscosity. Add 5 parts of phase-change microcapsules and 2 parts of antibacterial fiber, stir at room temperature for 20 minutes to stand still, pour the mixed sol into the mold and let it stand to obtain a wet gel with a certain strength, take the wet gel out of the mold, soak in absolute ethanol Aging in solution for 36h. Finally, the phase-change microcapsule composite silica airgel was obtained by drying under normal pressure at 60°C for 22 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com