Preparation method of micro-spherical aerogel based on super-hydrophobic surface, product obtained by using method and application of method

A super-hydrophobic surface and airgel technology, applied in the direction of silica, silicon oxide, etc., to achieve stable physical parameters, good controllability, and reduce the use of organic solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A microspherical SiO 2 The concrete preparation method of airgel, this method comprises the following steps:

[0036] Step S10, prepare a silica gel solution to form a silica sol, and prepare sodium silicate, water glass or organic silicon source by using an acid-base catalyzed two-step method.

[0037] At room temperature, adjust the pH value of the silica sol to 1-2 with hydrochloric acid with a mass concentration of 1-10%, and dilute it with water to a certain molar ratio in SiO 2 : Water = 1:5~200 range.

[0038] Then adjust the pH value of the above solution to 6-8 by adding ammonia water, and add a certain amount of non-volatile water-soluble reagents, such as ethylene glycol, propylene glycol, glycerol, etc., to control the volatilization speed of the solution. In addition, the present invention can also use other water-soluble reagents with a boiling point higher than 180°C.

[0039] Step S20, preparing the gel. Before the silica sol gels, the silica sol is p...

Embodiment 1

[0051] Prepared from commercially available silica sol, at room temperature, measure 20 mL of silica sol with a mass content of 20% water, dilute it with 70 mL of water, adjust the pH value of the silica sol to 2 with 10% hydrochloric acid, and let it stand for 6 hours.

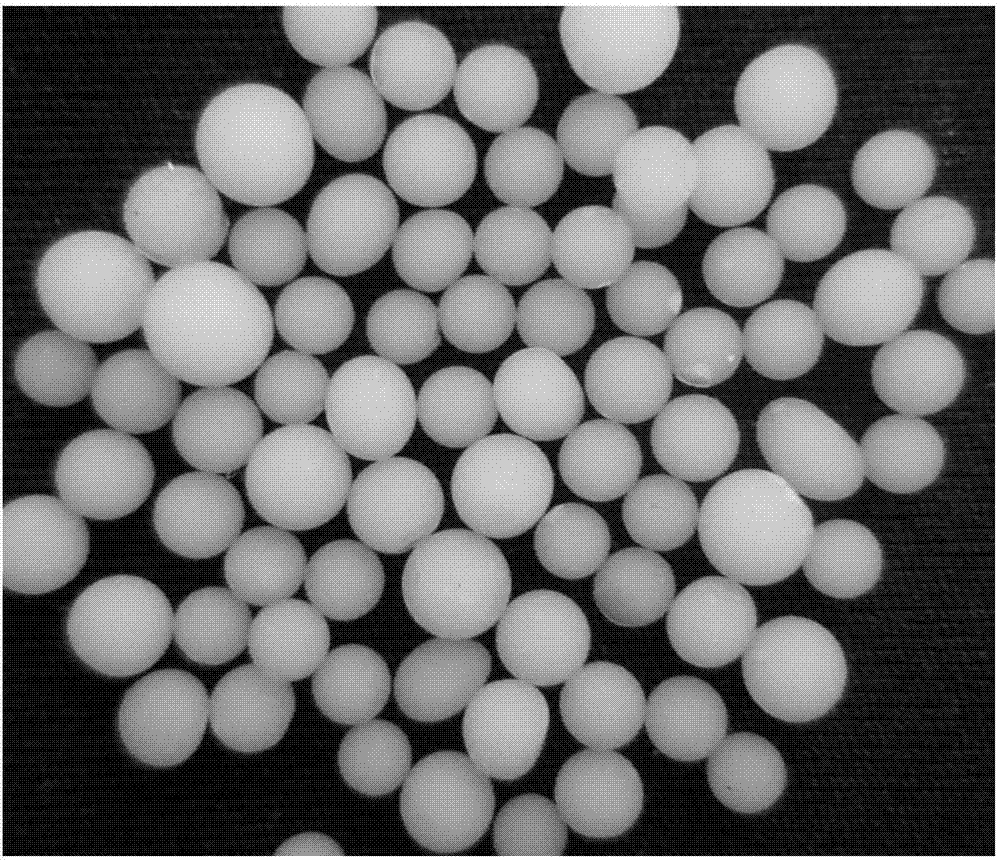

[0052] Then add ammonia water to adjust the pH value of the above solution to 8. Before the silica sol gel, quickly drop it on the surface of the superhydrophobic airgel film through the syringe, and drop silica sol microspheres of different sizes according to different size requirements. Make the diameter range from 1 to 4mm, and let it stand to gel.

[0053] Transfer the prepared wet gel microspheres to ethanol for soaking, and then age the gel with a mixture of water: ethanol = 1:5 by volume; 2The gel was subjected to solvent replacement twice, each time for 4 hours; then the solution of trimethylchlorosilane and n-hexane was mixed at a volume ratio of 3:10, and the microspherical SiO 2 The gel was soaked...

Embodiment 2

[0055] Prepared using commercially available silica sol. First, at room temperature, measure 20 mL of silica sol with a mass content of 20% water, dilute it with 70 mL of water, adjust the pH value of the silica sol to 2 with 10% hydrochloric acid, and let it stand for 6 hours.

[0056] Then add an appropriate amount of glycerin, and adjust the pH value of the above solution to 8 with ammonia water, and quickly pass through an airless sprayer to atomize the silica sol before the silica sol gel, and spray it on the superhydrophobic polytetrafluoroethylene, Let the gel sit.

[0057] Transfer the prepared wet gel microspheres to water, collect them and place them in ethanol for soaking, then age the gel with a mixture of water:ethanol=1:8 by volume; Microspherical SiO 2 The gel was subjected to solvent replacement twice, each time for 1 h; then hexamethyldisilazane and n-heptane were mixed at a volume ratio of 3:10, and the microspherical SiO 2 The gel was soaked in the mixtur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com