Iron-contained solid waste intelligent treatment system and control method thereof

A technology for disposal system and solid waste, applied in the field of metallurgy, can solve the problem that the zinc load affects the normal operation of blast furnace, dust, sludge, iron, carbon resources, etc., and achieves the effect of reducing the desulfurization burden of the converter, increasing the usage, and realizing the effect of recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Preferred embodiments of the present invention will be described in detail below.

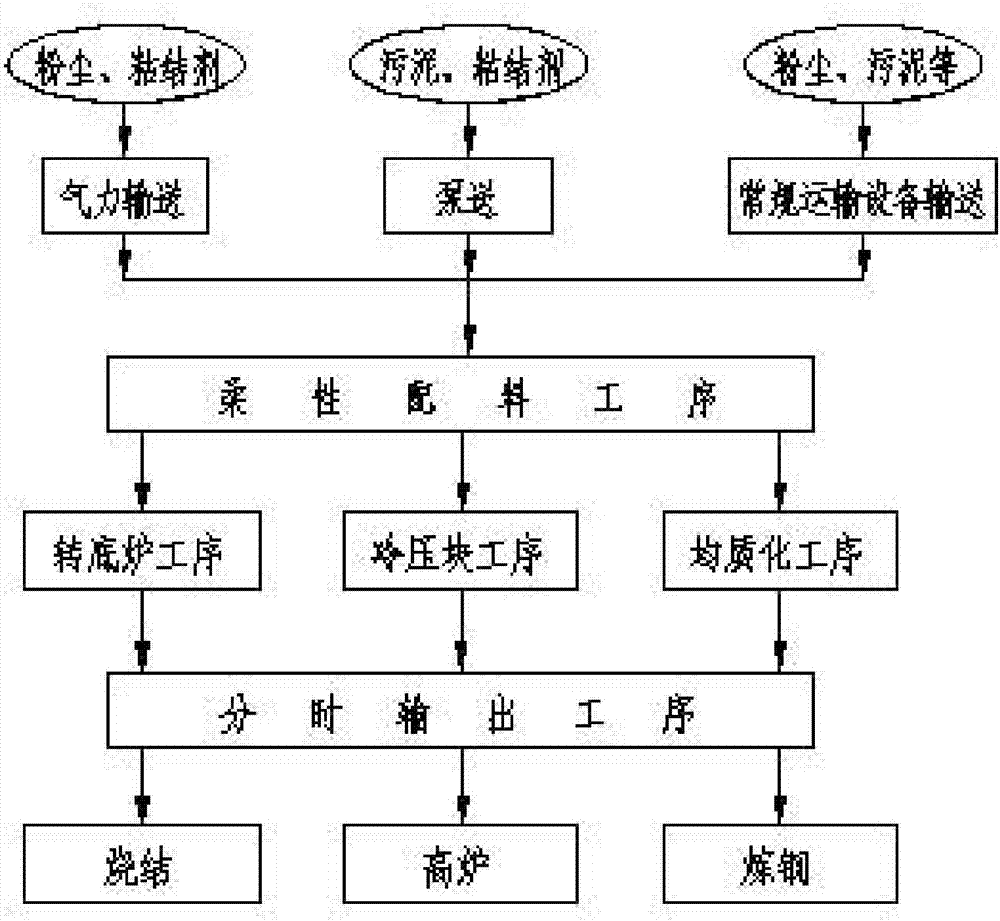

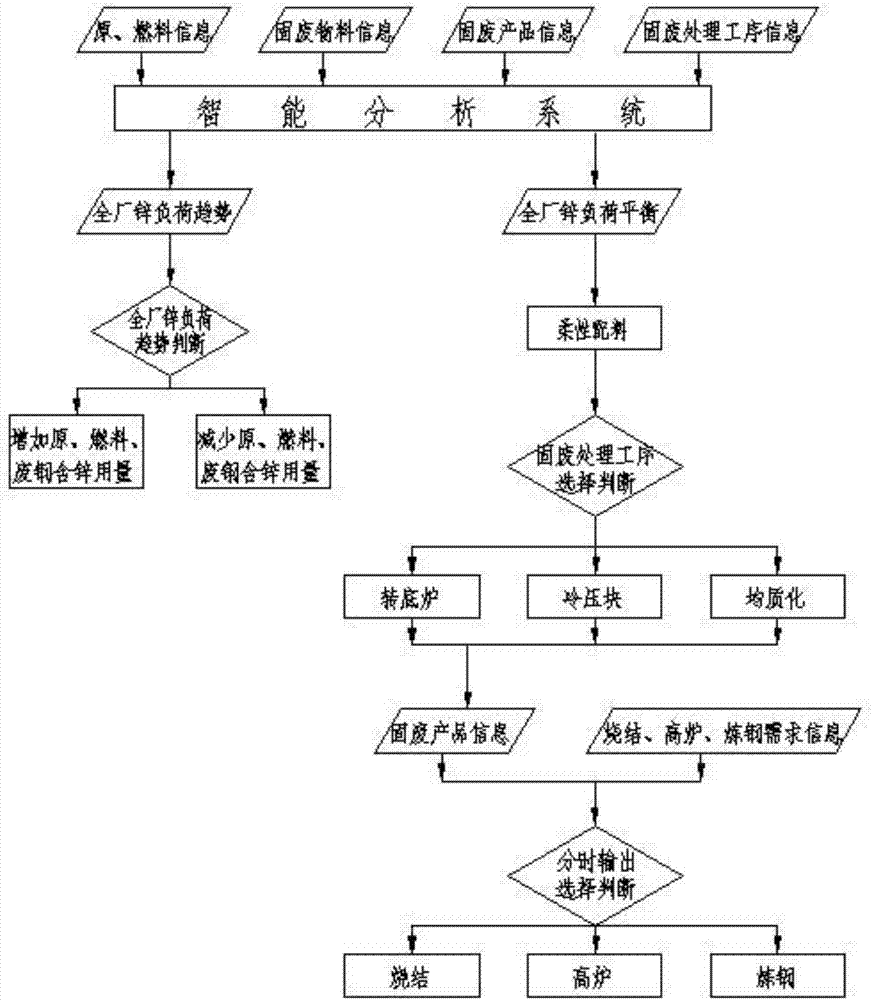

[0021] Such as figure 1 The process flow chart of the intelligent disposal system for iron-containing solid waste is shown, which includes input layer, batching layer, pretreatment layer, output layer and final treatment layer from top to bottom. The input layer divides the material into a mixed layer of dust and binder , mixed layer of sludge and binder, and mixed layer of dust and sludge. The batching layer is a flexible batching process for centralized batching of materials. Usually, the materials in one batching silo in a project can only go to one process, and the batching bin of the flexible batching process The materials can go to multiple specified processes as needed. Various iron-containing dust, dry sludge, binders, etc. enter the silo for storage. The silo is equipped with double outlets and connected to a quantitative feeder, which can send different materials to the homoge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com