Solid-liquid separation filter pressing equipment with filter plate dislocation prevention function

A solid-liquid separation and anti-displacement technology, which is applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of easy breeding of bacteria, single structure, and prone to dislocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

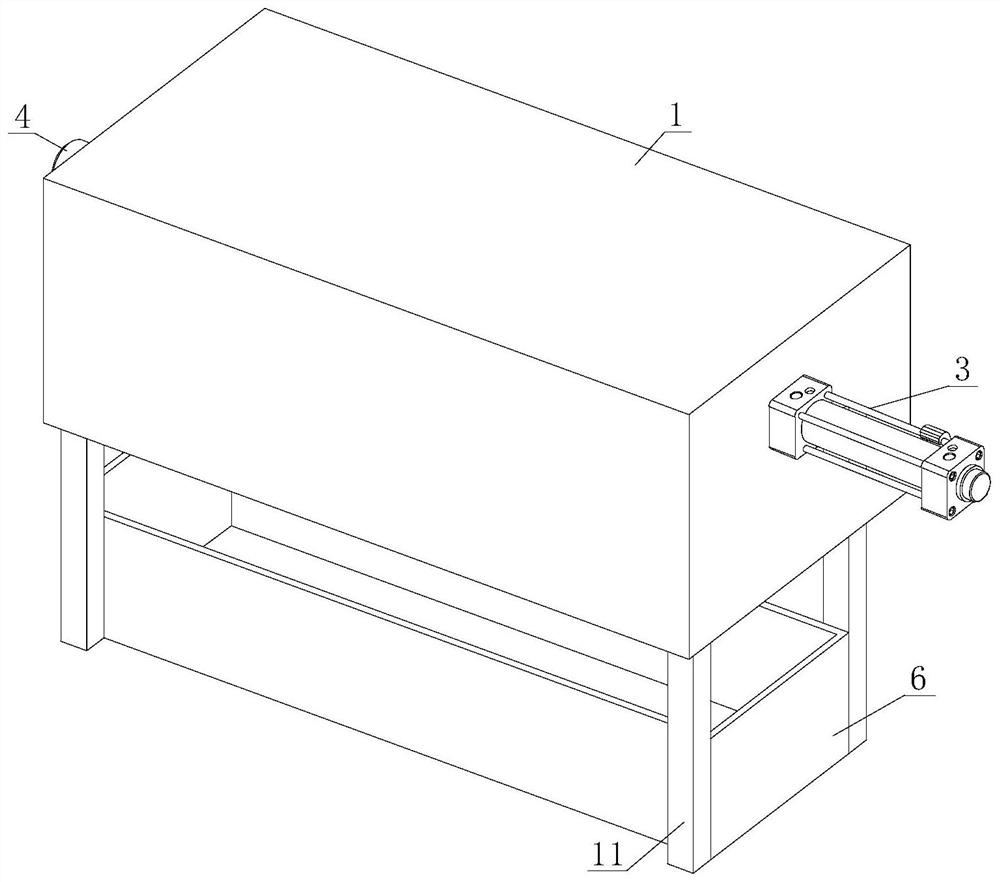

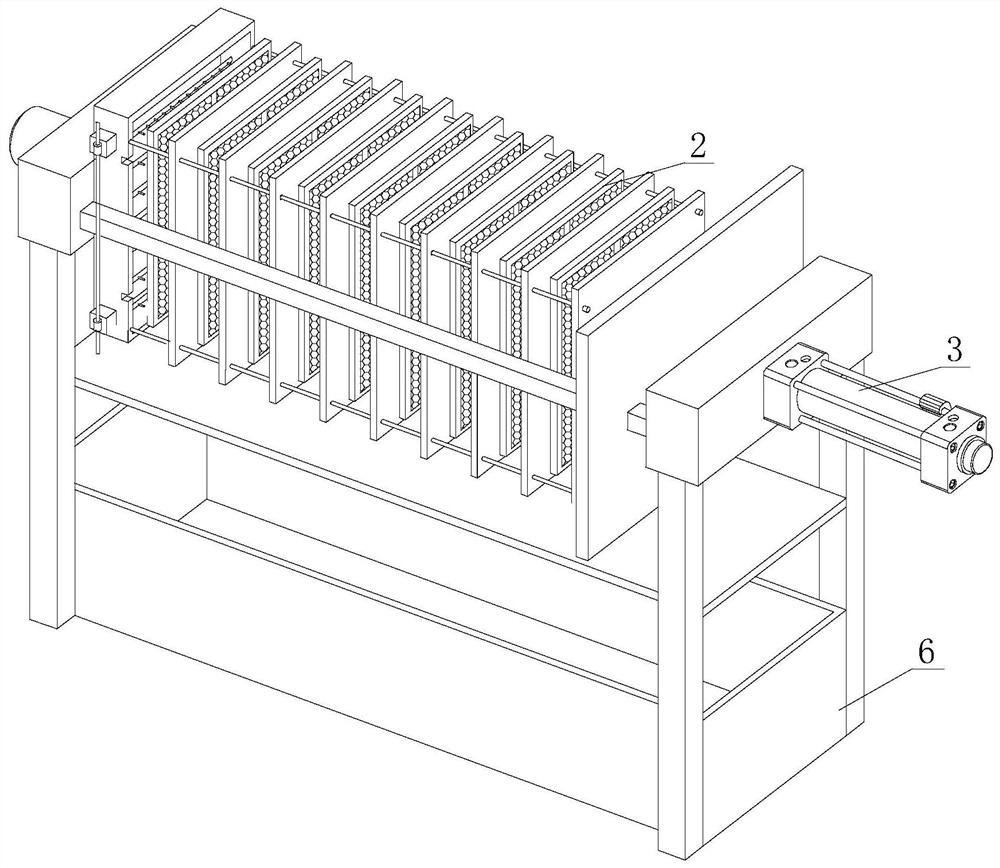

[0038] see Figure 1-Figure 2 , the solid-liquid separation filter press equipment with the filter plate anti-displacement function, comprising a filter press box 1, a support frame 11 is fixed below the filter press box 1, and a filter press assembly 2 is arranged inside the filter press box 1, The inside of the filter press box 1 is provided with a positioning extrusion device 3, the filter press assembly 2 is sleeved on the positioning extrusion device 3, the inside of the filter press assembly 2 is provided with an anti-displacement device 4, and the anti-dislocation device 4 is sleeved with a scraper assembly 5 A collecting device 6 is arranged under the filter press box 1 , and the collecting device 6 is arranged inside the support frame 11 .

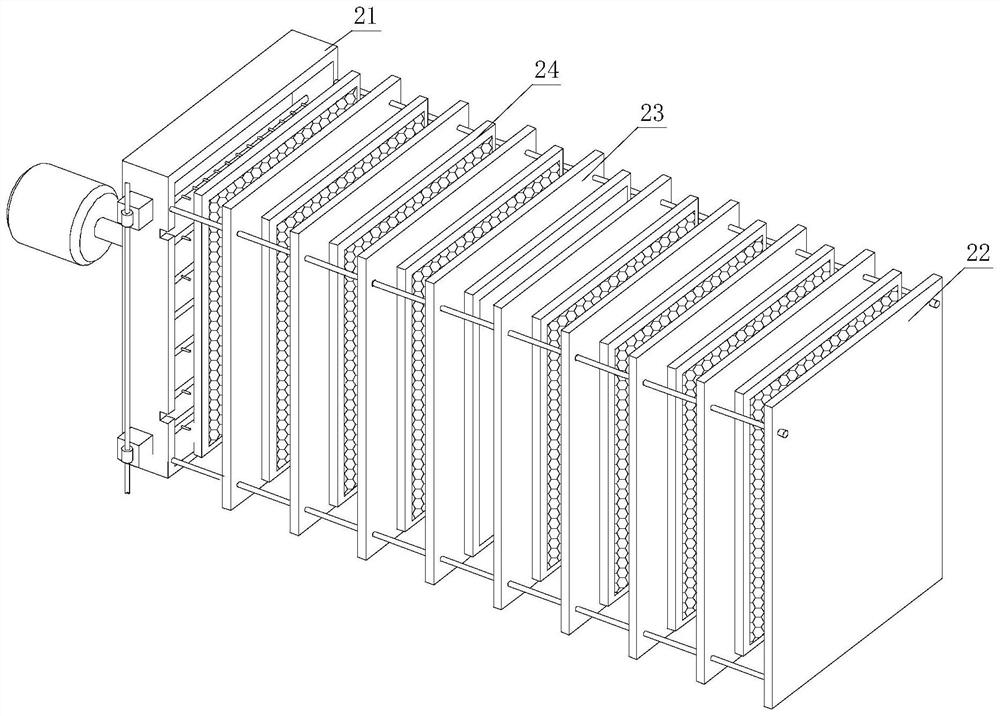

[0039] see Figure 3-Figure 4 , the filter press assembly 2 comprises a fixed press plate 21, a movable press plate 22, a filter frame 23, a filter plate 24 and a filter cloth 25, a filter plate 24 is arranged at the side end of ...

Embodiment 2

[0045] see Figure 12 , the solid-liquid separation filter press equipment with the filter plate anti-displacement function, comprising a filter press box 1, a support frame 11 is fixed below the filter press box 1, and a filter press assembly 2 is arranged inside the filter press box 1, The inside of the filter press box 1 is provided with a positioning extrusion device 3, the filter press assembly 2 is sleeved on the positioning extrusion device 3, the inside of the filter press assembly 2 is provided with an anti-displacement device 4, and the anti-dislocation device 4 is sleeved with a scraper assembly 5 A collection device 6 is arranged below the filter press box 1, and the collection device 6 is arranged inside the support frame 11. The filter press assembly 2 includes a fixed press plate 21, a movable press plate 22, a filter frame 23, a filter plate 24 and a filter cloth 25, and the fixed press plate 21 side end is provided with filter plate 24, and filter plate 24 one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com