Solid-liquid separation filter pressing equipment with shock absorption and dislocation prevention functions

A solid-liquid separation and anti-dislocation technology, applied in filtration separation, mechanical equipment, separation methods, etc., can solve the problems affecting the smooth progress of solid-liquid separation, unstable filter plate walking, affecting work efficiency, etc., to increase pressure, reduce voids, the effect of increasing the efficiency of the filter press

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

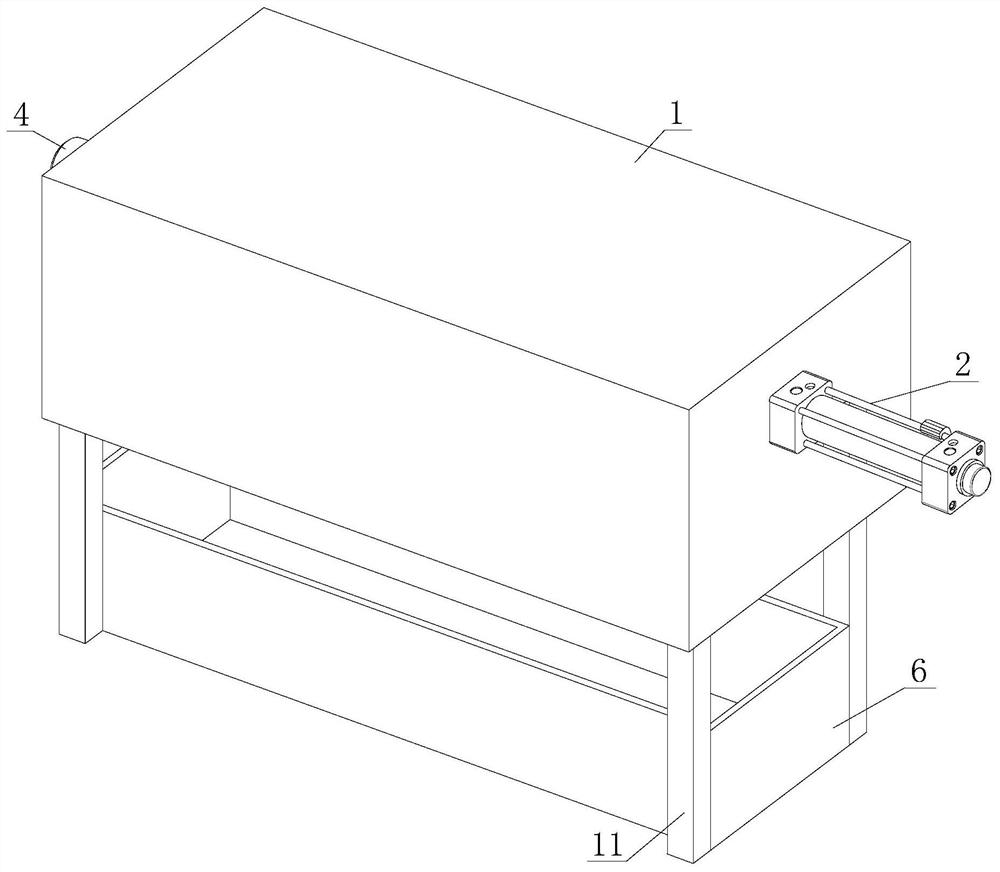

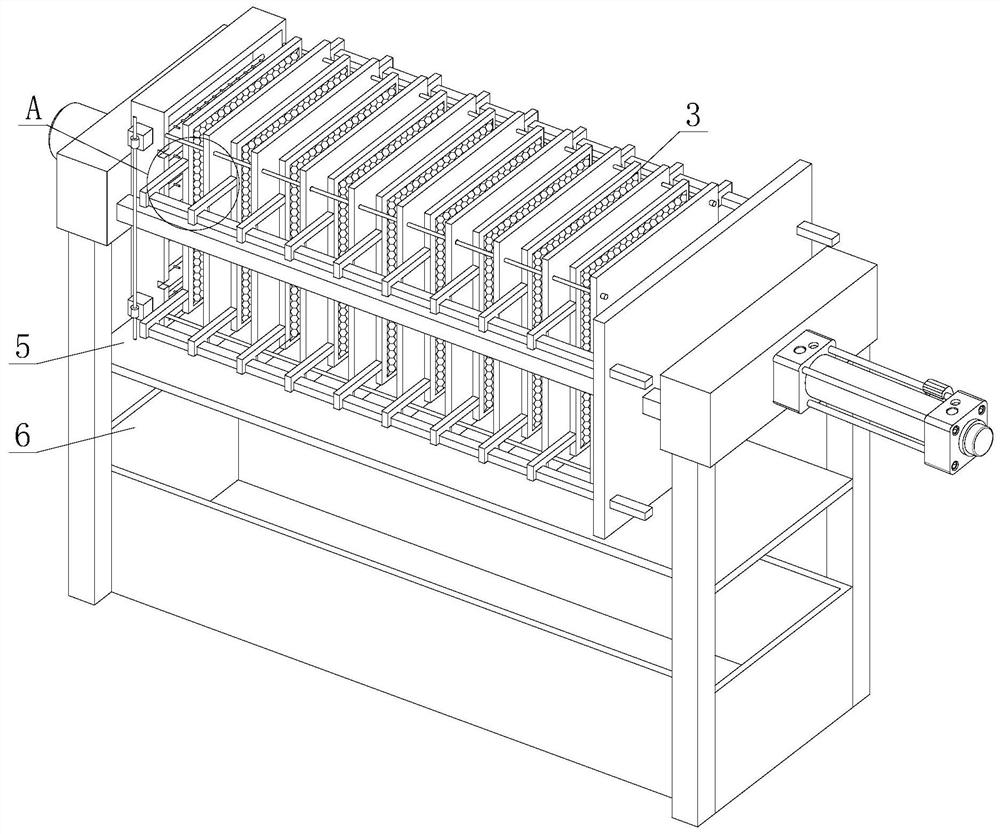

[0037] see Figure 1-Figure 2 , a solid-liquid separation filter press device with the function of shock absorption and anti-displacement, comprising a box body 1, a support frame 11 is connected to the bottom of the box body 1, a power assembly 2 is arranged at the side end of the box body 1, and a pressure filter is arranged inside the box body 1. The filter assembly 3 and the shock absorber 4 are arranged in the filter press assembly 3 , the blanking plate 5 is arranged below the filter press assembly 3 , the blanking plate 5 is arranged between the support frames 11 , and the receiving box 6 is provided below the support frame 11 .

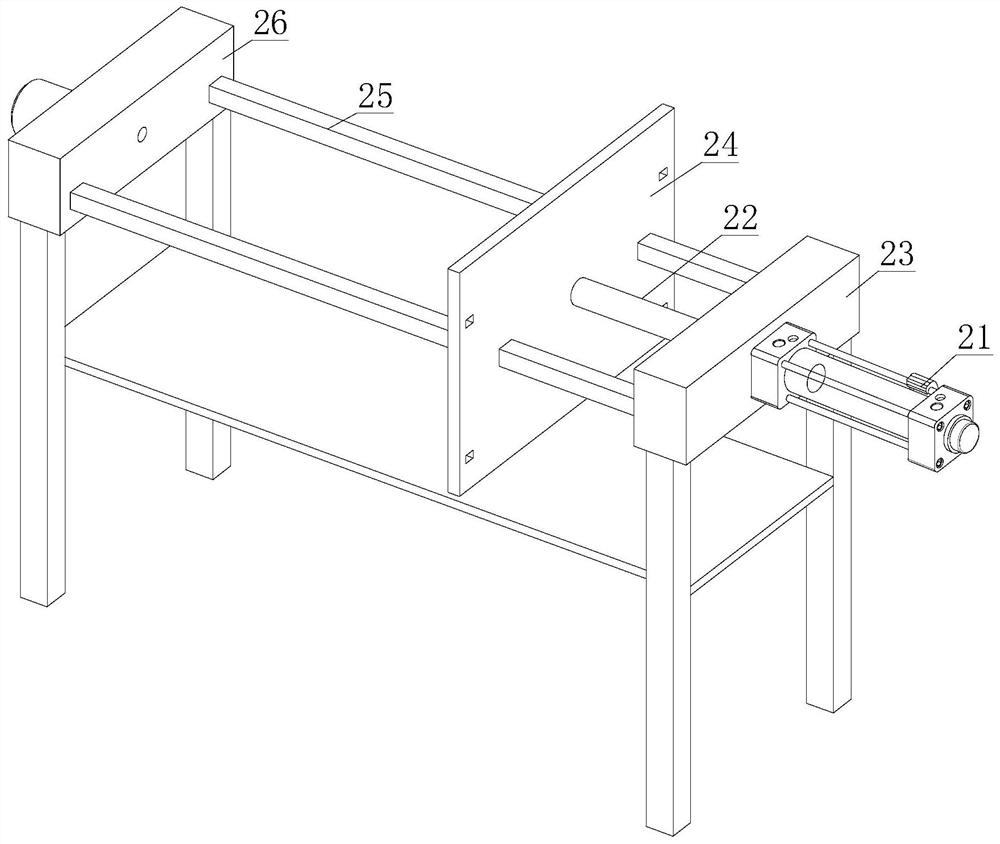

[0038] see image 3 , the power assembly 2 includes a pressure cylinder 21, a pressure rod 22, a hydraulic seat 23, a pressure plate 24, a support rod 25 and a fixed seat 26, the pressure cylinder 21 is fixed on the side end of the hydraulic seat 23, and the hydraulic seat 23 and the fixed seat 26 are formed by The two support rods 25 are con...

Embodiment 2

[0043] see Figure 11 , a solid-liquid separation filter press device with the function of shock absorption and anti-displacement, comprising a box body 1, a support frame 11 is connected to the bottom of the box body 1, a power assembly 2 is arranged at the side end of the box body 1, and the inside of the box body 1 The filter press assembly 3 is set, and the shock absorber 4 is arranged in the filter press assembly 3. The power assembly 2 includes a pressure cylinder 21, a pressure rod 22, a hydraulic seat 23, a pressure plate 24, a support rod 25 and a fixing seat 26, and the pressure cylinder 21 is fixed on the hydraulic pressure. The side end of the seat 23, the hydraulic seat 23 and the fixed seat 26 are connected and fixed by two bracket rods 25, the output end of the pressure cylinder 21 is connected to the pressure rod 22, and the pressure rod 22 runs through the hydraulic seat 23 to connect with the pressure plate 24, and there are 24 sets of pressure plates Connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com