Thick needle color-developing jacquard screen cloth and manufacturing method thereof

A production method and thick needle technology, applied in knitting, warp knitting, application and other directions, can solve the problems of unclear V-point jacquard structure, poor three-dimensional feeling, poor V-point jacquard stability and wear resistance, etc. Clear, good shape retention, high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further explain the technical solution of the present invention, it will be described in detail below in conjunction with the accompanying drawings.

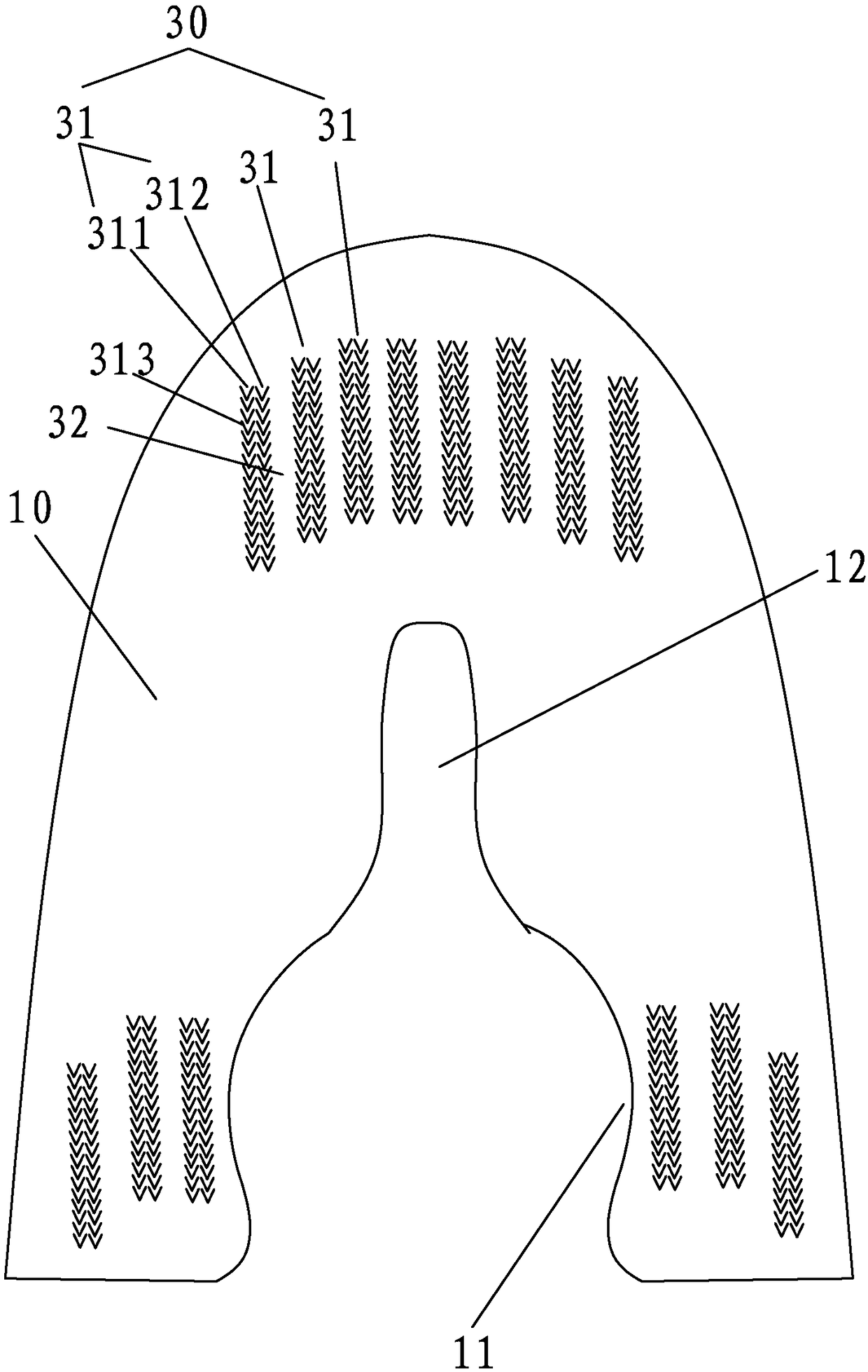

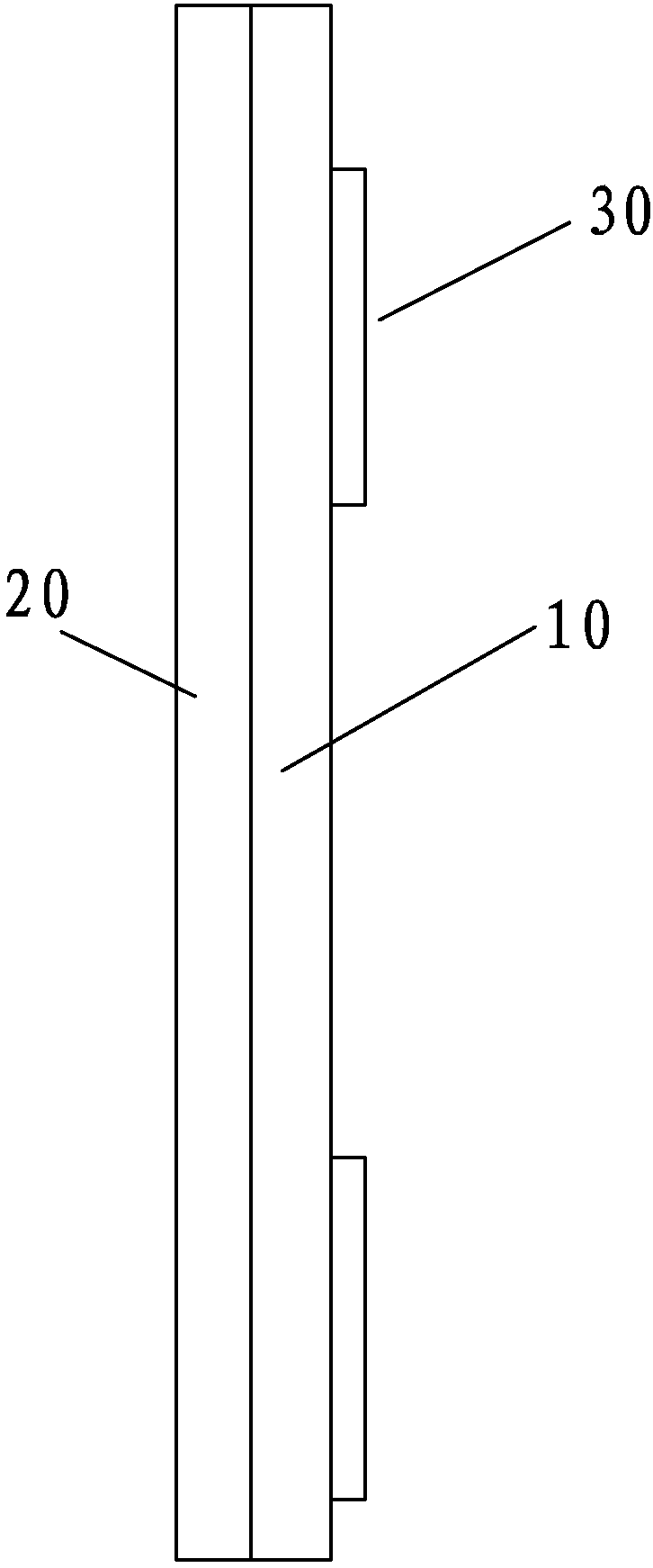

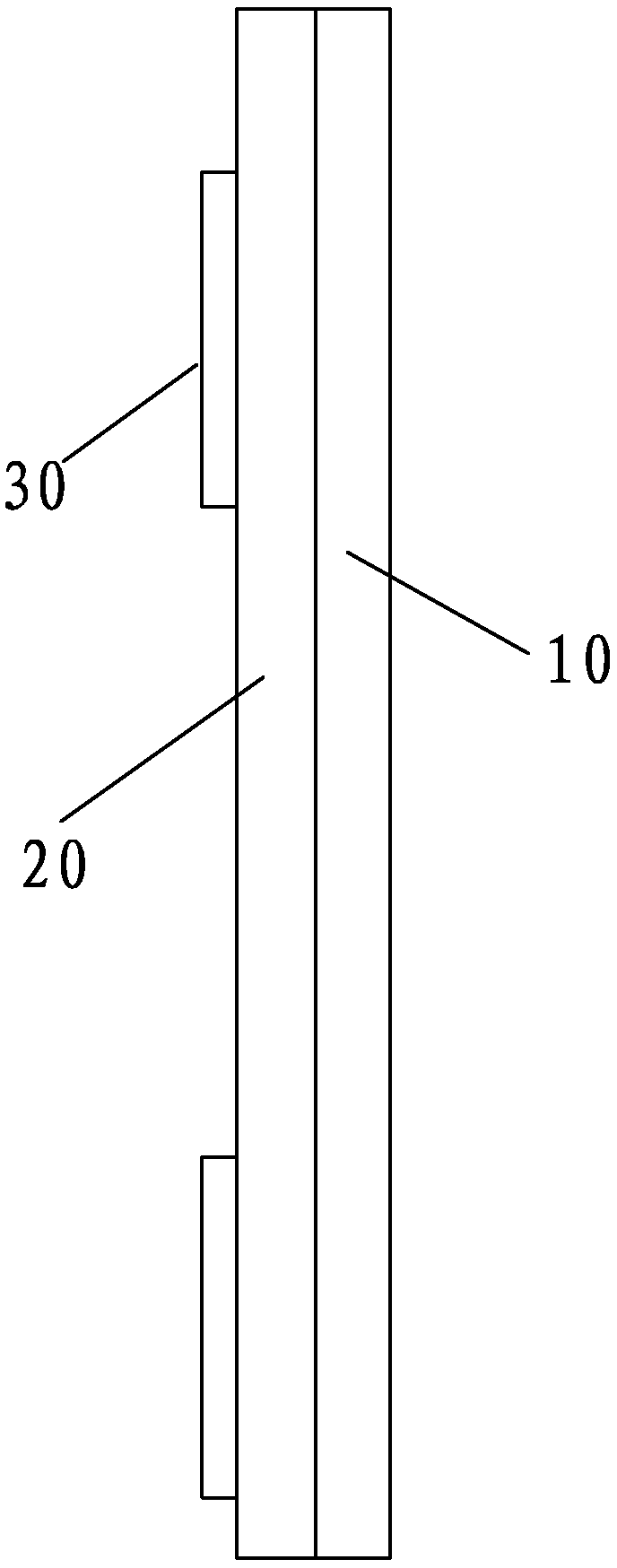

[0031] refer to Figure 1 to Figure 4 , a kind of jacquard jacquard mesh cloth with thick needle color development, the mesh cloth includes a mesh cloth body, the mesh cloth body has a surface layer 10, a bottom layer 20 and a connecting yarn for connecting the surface layer 10 and the bottom layer 20, and the surface layer 10 and / or Or a jacquard pattern 30 is formed on the bottom layer 20, and the jacquard pattern 30 is integrally woven from 500D to 1500D jacquard yarns.

[0032] In the present invention, the surface layer 10, the bottom layer 20 and the jacquard pattern 30 are integrally knitted by a double needle bed double jacquard warp knitting machine.

[0033] As a preferred mode of the present invention, the jacquard yarn is 600D polyester high elastic yarn, and the surface layer 10 is interwoven wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com