Multi-combination steel keel

A steel keel and keel technology, which is applied in the field preparation of formwork/formwork components and building components, construction, etc., can solve the problems of large material loss and single size, achieve strong rigidity and twist resistance, and facilitate installation and disassembly , The effect of reducing engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

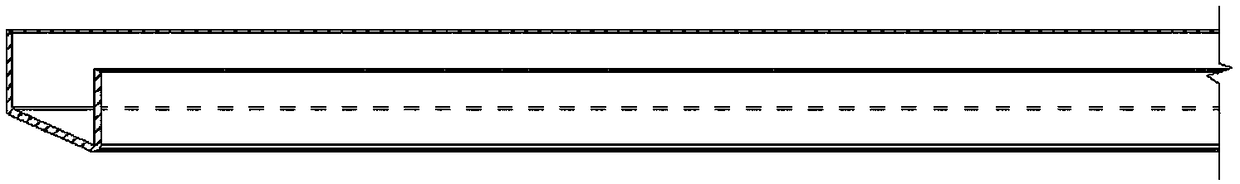

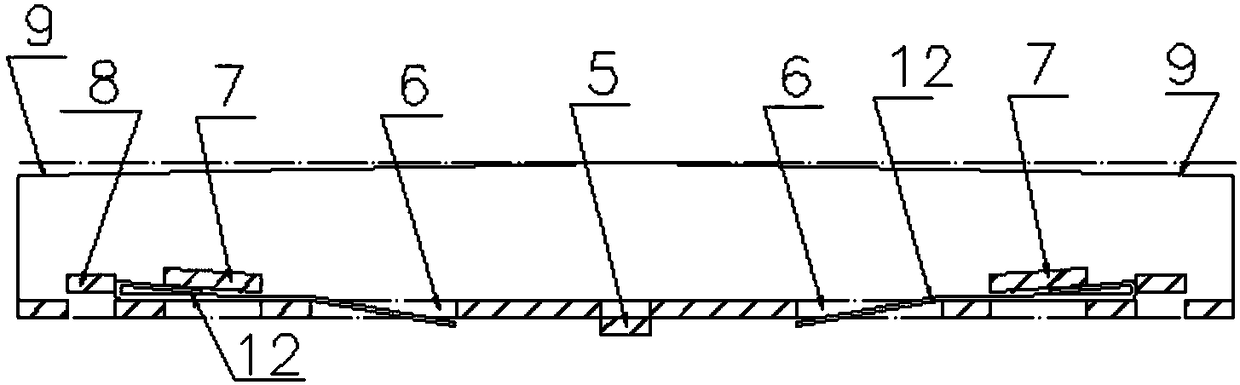

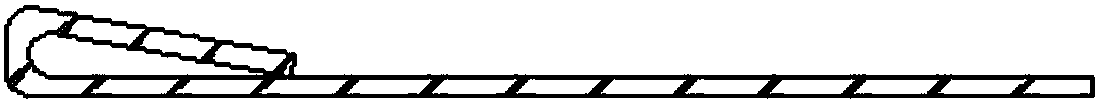

[0020] refer to Figure 1-7 , a multi-combination steel keel, including keel connectors and keel frames. The keel connector is divided into the main part of the connector and the accessories of the connector. The lower side of the keel frame and the connector accessory slope is welded through the main keel welding port (13), and is connected into one main keel. Both ends of the bottom of the main part of the connector are provided with snap-in units of the main part, and each snap-in unit of the main part includes a tongue groove (6), a fixed tongue convex groove (7), a tongue stopper (8), and a snap tongue (12). A concave shelf (5) is provided in the middle of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com