Piston type air compressor, motion conversion mechanism and vehicle air compressor

A technology of piston movement and piston type, which is applied in the field of air compressors to achieve the effects of enhanced structural balance performance, excellent balance performance, and increased displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

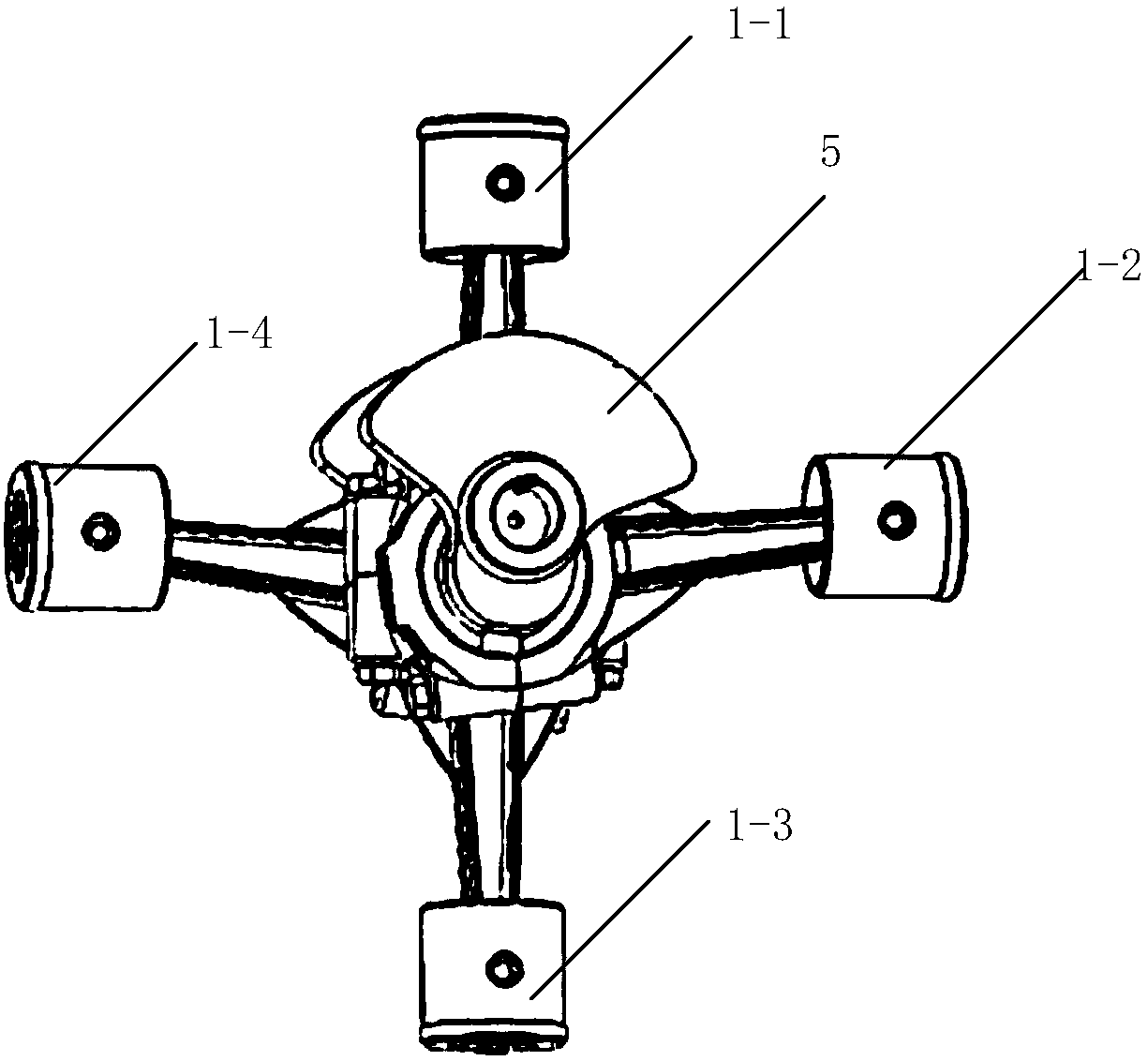

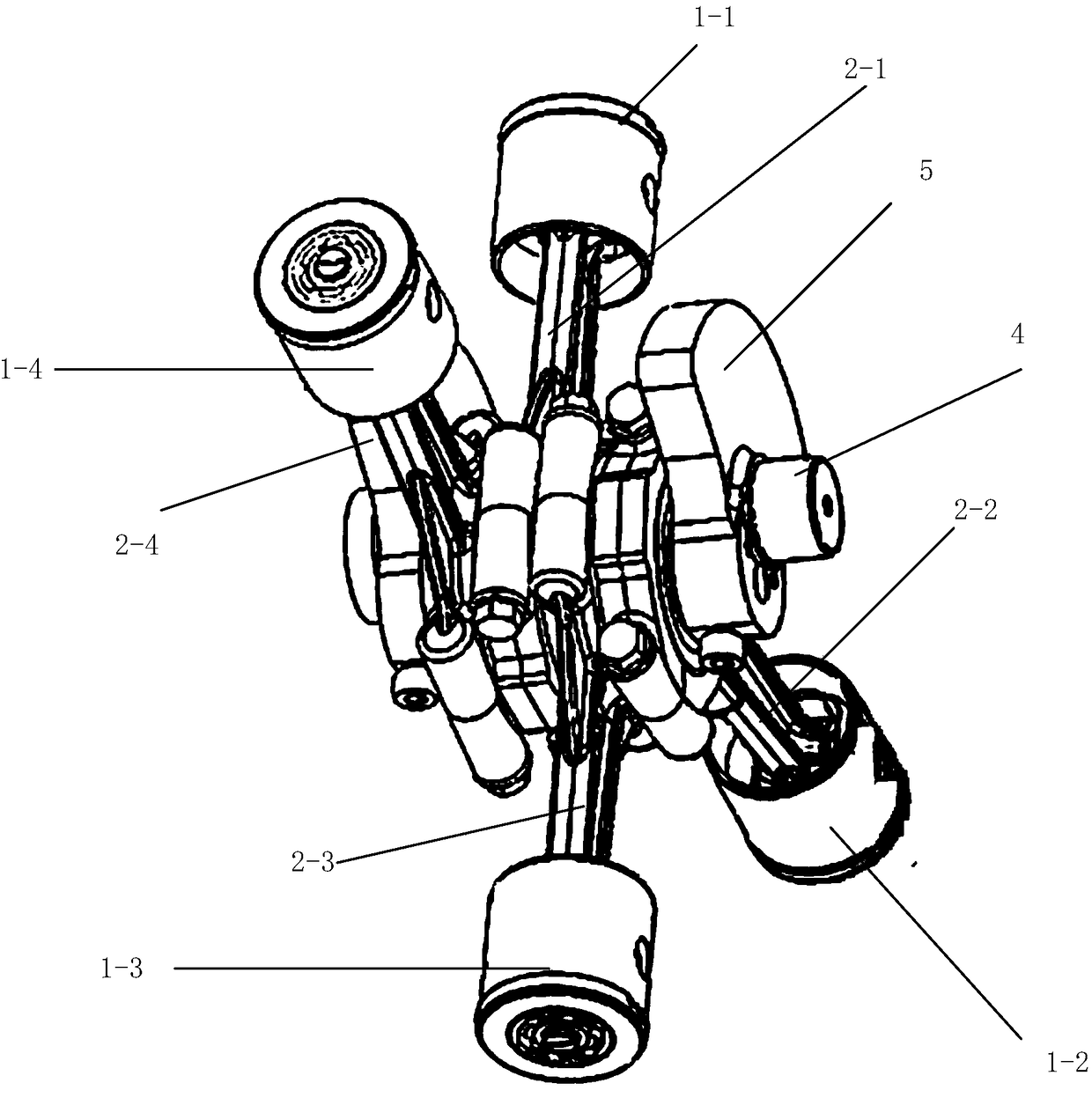

[0035] The present embodiment is a piston air compressor with 8-cylinder double cross structure (or double X structure). Figure 4 and Figure 5 The schematic diagram of the structure of the piston air compressor of this embodiment is shown. In this embodiment, the piston compressor of this embodiment is mainly described in combination with its arrangement form, and the body, driving device and accessories of the compressor are not described. There are too many descriptions, and relevant parts can refer to existing piston compressors.

[0036] Please refer to Figure 4 and Figure 5 , the 8-cylinder double cross structure of this embodiment includes eight compression cylinders 20, which are placed on both sides of the compressor, four cylinders on one side, and the four cylinders on one side are arranged in a cross shape, and a driving device is arranged in the middle. In the example, the driving device is a driving motor 10 . The whole machine is arranged on the base 30 ....

Embodiment 2

[0042] The piston air compressor of this embodiment is the same as that of the first embodiment above, and is also an 8-cylinder double cross structure. block structure. Each rotary-reciprocating conversion mechanism includes four single-acting pistons and four round sliders, and the arrangement of the pistons is the same as in the first embodiment. An oil-free bearing can be used between the piston and the slider, and other structures of the piston air compressor in this embodiment can be the same as that of the first embodiment above, and will not be discussed here. The piston air compressor of this embodiment has the same technical effect as the above embodiment, and furthermore, the secondary reciprocating moment of inertia is also zero. Has a better balancing effect.

Embodiment 3

[0044] In this embodiment, the piston air compressor is a 4-cylinder cross-shaped structure, that is, a rotary reciprocating conversion device is used. The rotary reciprocating motion conversion device can adopt the structure of the above-mentioned embodiment 1 or the structure of the above-mentioned embodiment 2. Other aspects of the piston air compressor in this embodiment can be the same as the above-mentioned embodiment, and will not be discussed here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com