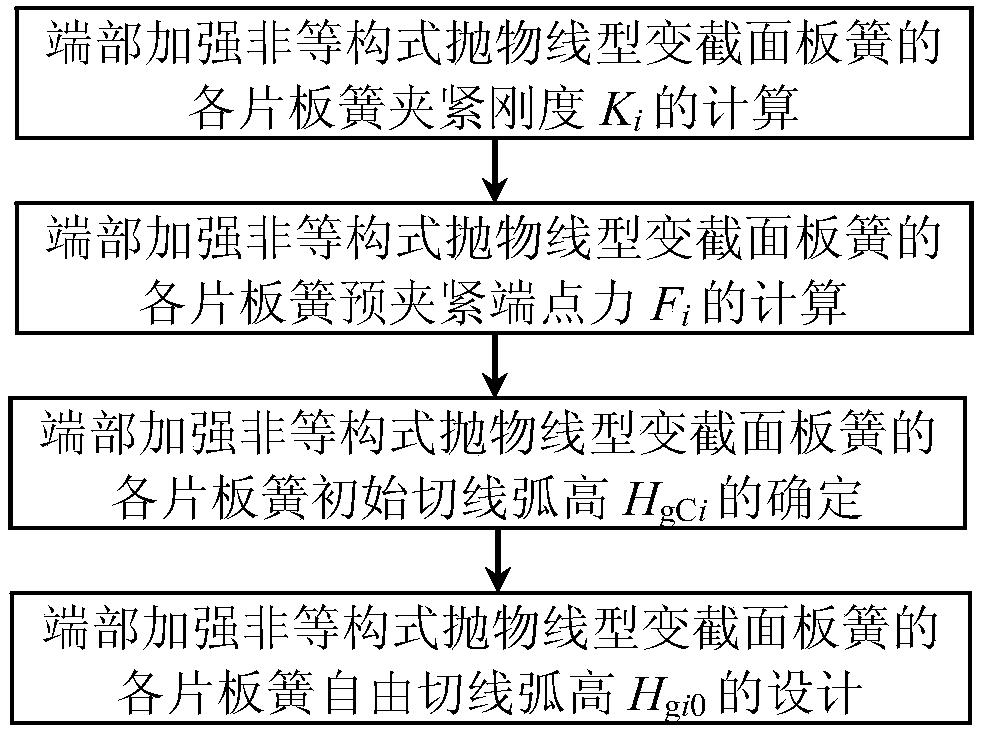

Design method for end-reinforced non-isomorphic taper-leaf spring free tangent arc heights

A technology of non-equal structure and variable cross-section, which is applied in the design characteristics of spring/shock absorber, leaf spring, computer-aided design, etc. Strengthen the calculation of complex clamping stiffness of non-isomorphic parabolic variable-section leaf springs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

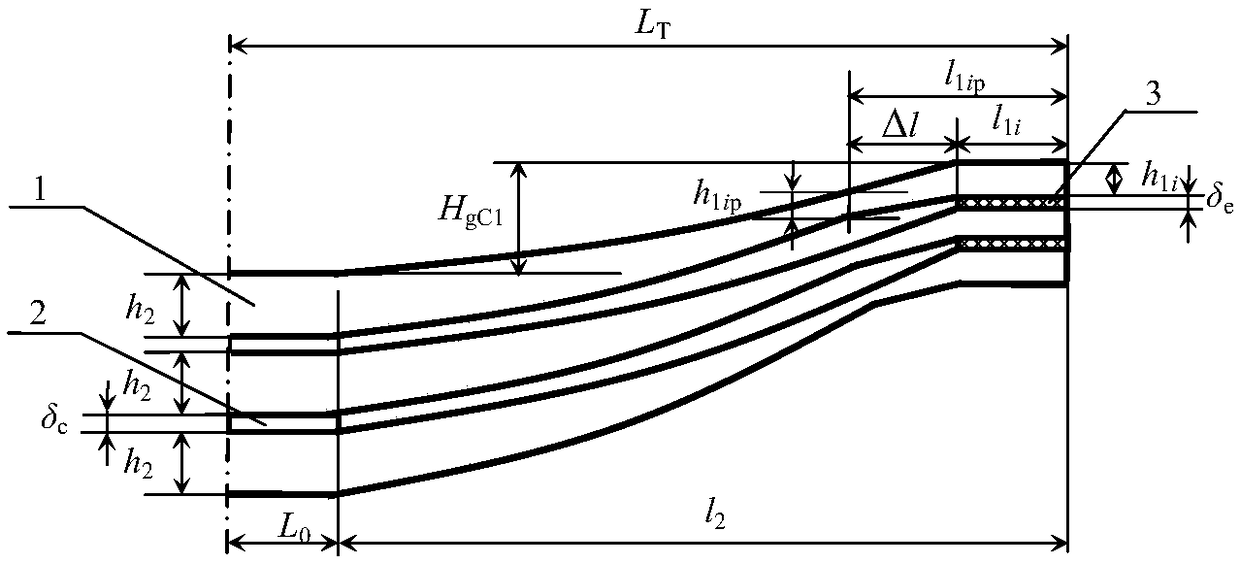

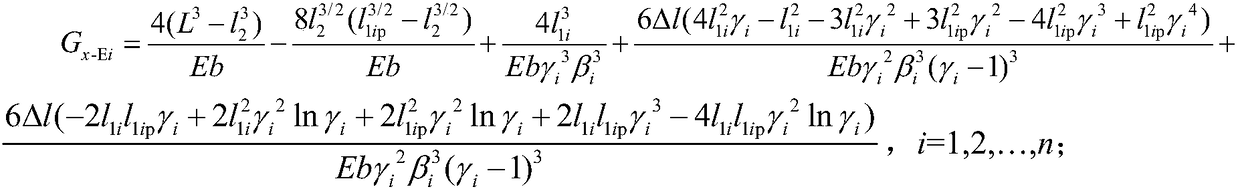

[0028] Example one: the width of the non-isostructured parabolic variable cross-section leaf spring of a certain end strengthened b=60mm, half of the effective length L T =575mm, half the length of the straight section of the root clamped by the riding bolt L 0 =50mm, the horizontal length of the diagonal line Δl=30mm, and the elastic modulus E=200GPa. The number of leaf spring n=3, the thickness of the straight section of the root of each leaf spring h 2 =18mm, the horizontal distance from the root of the parabolic segment to the end point of the leaf spring l 2 =L T -L 0 =525mm; the end thickness of the parabolic section of each leaf spring h 11p = 8mm, h 12p =7mm, h 13p =6mm; the thickness of the flat end of each leaf spring h 11 = 9mm, h 12 = 8mm, h 13 =7mm; the thickness ratio β of the parabolic segment of each leaf spring 1 =h 11p / h 2 = 0.4444, β 2 =h 12p / h 2 = 0.3889, β 3 =h 13p / h 2 =0.3333, the thickness ratio of the diagonal line γ 1 =h 11 / h 11p = 1.1250, γ 2 =h 12 / h...

Example Embodiment

[0058] The second embodiment: the width of the non-isostructured parabolic variable cross-section leaf spring of a certain end strengthened b=60mm, half of the effective length L T =575mm, half the length of the straight section of the root clamped by the riding bolt L 0 =50mm, the horizontal length of the diagonal line Δl=30mm, and the elastic modulus E=200GPa. The number of leaf springs n=4, the thickness of the root flat section of each leaf spring is h 2 =16mm, the horizontal distance from the root of the parabolic segment to the end point of the leaf spring l 2 =L T -L 0 =525mm; the end thickness of the parabolic section of each leaf spring h 11p = 8mm, h 12p =7mm, h 13p = 6mm, h 14p =5mm, the thickness of the flat end of each leaf spring h 11 = 9mm, h 12 = 8mm, h 13 =7mm, h 14 = 6mm. The thickness ratio of the parabolic segment of each leaf spring β 1 =h 11p / h 2 =0.5, β 2 =h 12p / h 2 = 0.4375, β 3 =h 13p / h 2 = 0.375, β 4 =h 14p / h 2 =0.3125; the thickness ratio of the obl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com