Calibration method of pressure sensor based on mc8051

A pressure sensor and calibration method technology, which is applied in the calibration/testing of force/torque/power measuring instruments, measuring fluid pressure, instruments, etc., can solve problems such as low accuracy of curve and surface fitting, unstable network, and a large number of samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

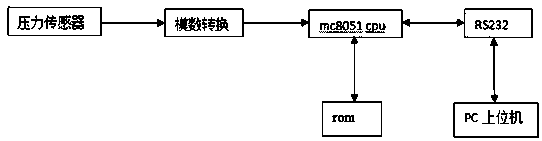

[0026] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

[0027] A kind of pressure sensor calibration algorithm based on 8051 of the present invention, comprises the following steps,

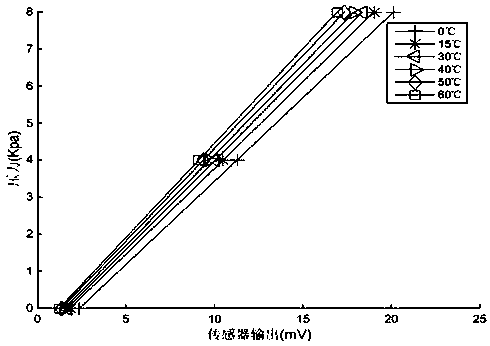

[0028] Step S1: Select the pressure sensor, preset n temperature values and m pressure values, where the n temperature values are respectively t 0 , t 1 , t 2 , t 3 , t 4 , t 5 , t 0 ~t 2 is the low normal temperature section, t 2 ~t 5 for the high temperature section;

[0029] Step S2: Fix the temperature value unchanged, carry out the pressure sensor test, and perform polynomial fitting on the pressure value P and the output voltage u to obtain the P-U function p n = f n (u);

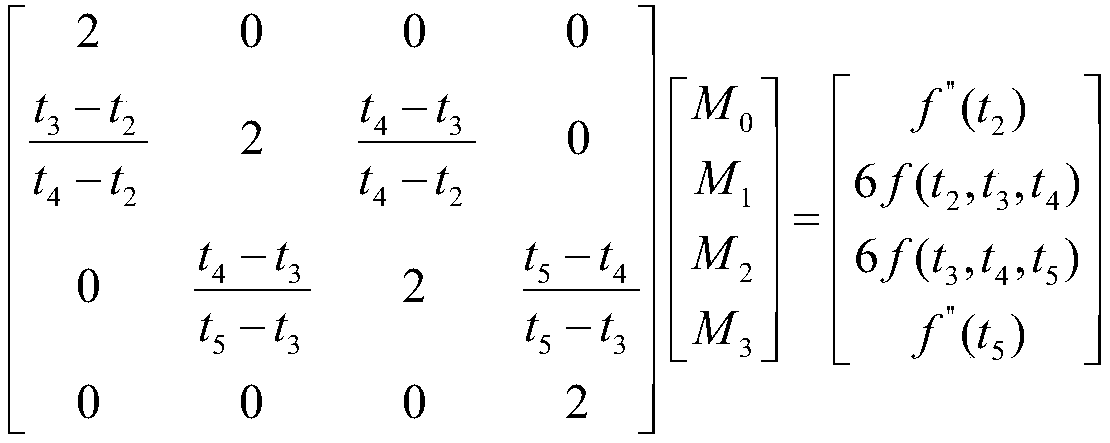

[0030] Step S3: Test the pressure sensor in the low normal temperature section and the high temperature section respectively, and perform the following treatments respectively;

[0031] (1) Under the low normal temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com