An Ultrasonic-Assisted Equal Channel Angular Stretch Processing Method

An equal channel angle, ultrasonic-assisted technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as lowering the pulling force, and achieve the effect of greatly reducing the pulling force, softening and deformation resistance, and facilitating continuous processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

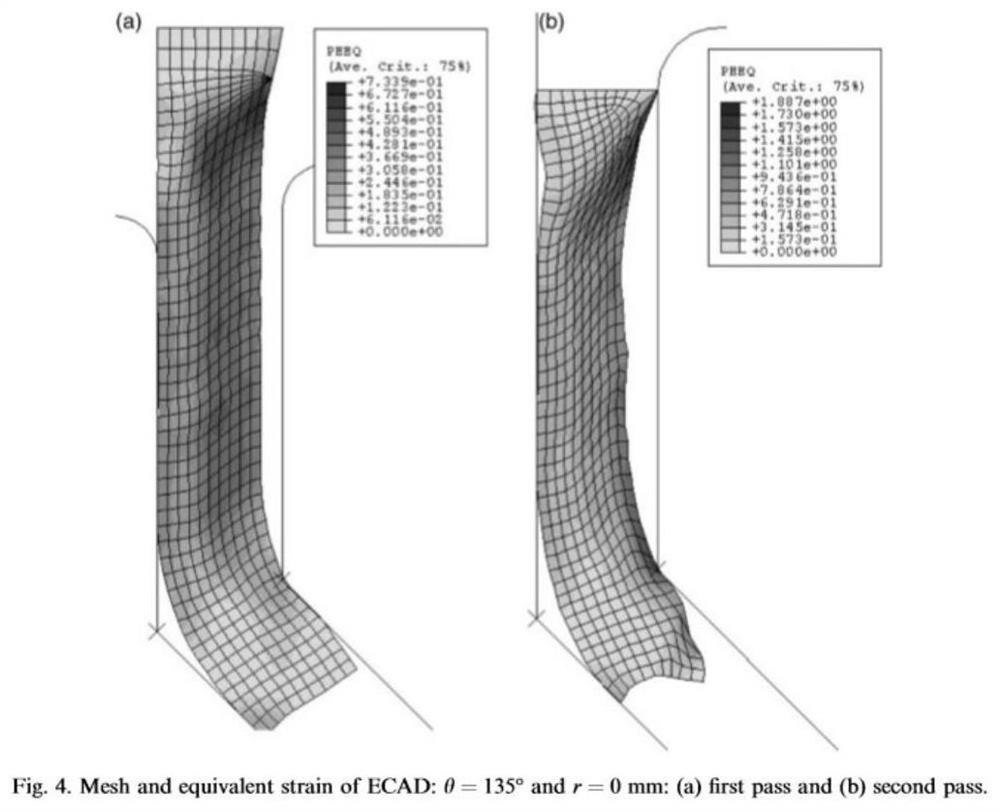

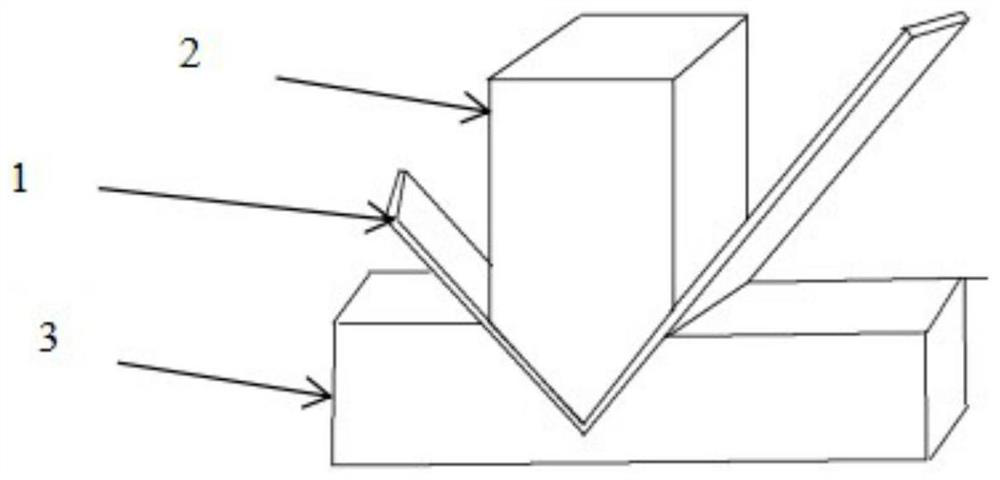

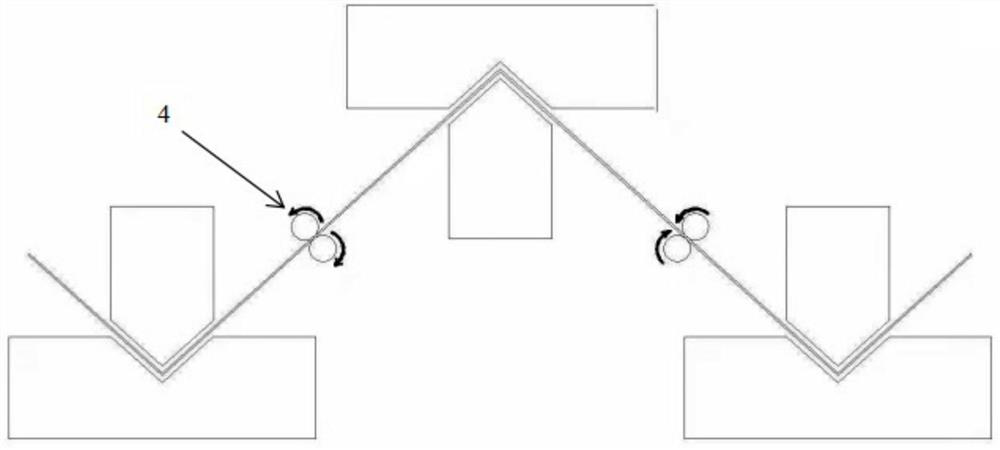

[0052] Ultrasonic-assisted equal-channel angular stretching of 100 micron T2 rolled copper foil, the device system such as figure 2 with 3 As shown, this ultrasonic-assisted equal-channel angular stretching processing method comprises the following steps:

[0053] (1) Clean the surface of T2 rolled copper foil to remove dirt;

[0054] (2) Apply inert lubricating oil on the surface of copper foil to form an oil film for protection and lubrication;

[0055] (3) The intersection angle of the V-shaped channel of the ultrasonic-assisted equal-channel angular stretching device is 90°, the amplitude of the ultrasonic impact head is 20 microns, and the vibration frequency is 20KHZ; the angular thickness of the channel is 120 microns; the V-shaped ultrasonic tool punch and V-shaped The base is made of high-hardness and wear-resistant high-carbon steel; water cooling is used to cool down;

[0056] (3) Turn on the ultrasonic device of the processing system, and pass the foil forward ...

Embodiment 2

[0062] Ultrasonic-assisted equal-channel angular stretching of 50 micron 304 stainless steel foil, the device system such as figure 2 with 3 As shown, this ultrasonic-assisted equal-channel angular stretching processing method comprises the following steps:

[0063] (1) Clean the surface of the stainless steel foil to remove dirt;

[0064] (2) Apply inert lubricating oil on the surface of the steel foil to form an oil film for protection and lubrication;

[0065] (3) The intersection angle of the V-shaped channel of the ultrasonic-assisted equal-channel angular stretching device is 120°, the amplitude of the ultrasonic impact head is 15 microns, and the vibration frequency is 28KHZ; the angular thickness of the channel is 65 microns; the V-shaped ultrasonic tool punch and V-shaped The base is made of high hardness and wear-resistant hard alloy tungsten steel; it is cooled by water;

[0066] (3) Turn on the ultrasonic device of the processing system, and pass the foil forwa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com