GIS loop resistance testing device and method without removing grounding rows

A technology of loop resistance and testing equipment, which is applied in the direction of measuring equipment, measuring resistance/reactance/impedance, measuring electrical variables, etc. It can solve the problems of threatening the personal safety of operators, affecting the efficiency of on-site work, and consuming time and effort for grounding bars, etc., to achieve Simplify the operation process, eliminate the risk of induction electric injury, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

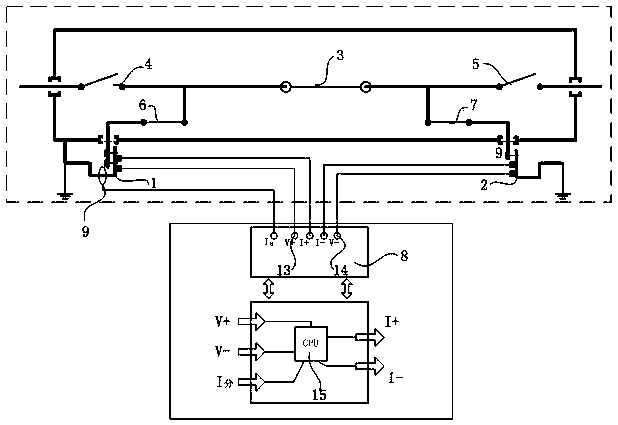

[0027] Such as figure 1Shown is the first embodiment of the GIS loop resistance testing device and method without removing the grounding bar of the present invention. The GIS loop is located inside the GIS equipment shell, including the first grounding bar 1, the second grounding bar 2, the GIS switch 3, The first knife switch 4 and the second knife switch 5, the first knife switch 4, the GIS switch 3, and the second knife switch 5 are connected in series to form a GIS main circuit, and the first grounding bar 1 is connected in parallel to the first Between the knife switch 4 and the GIS switch 3, the second ground bar 1 is connected in parallel between the second knife switch 5 and the GIS switch 3; the first ground bar 1, the second ground bar 2 and the GIS main The first grounding knife switch 6 and the second grounding knife switch 7 are respectively connected between the loops, and a parallel shunt is formed between the first grounding bar 1, the second grounding bar 2 an...

Embodiment 2

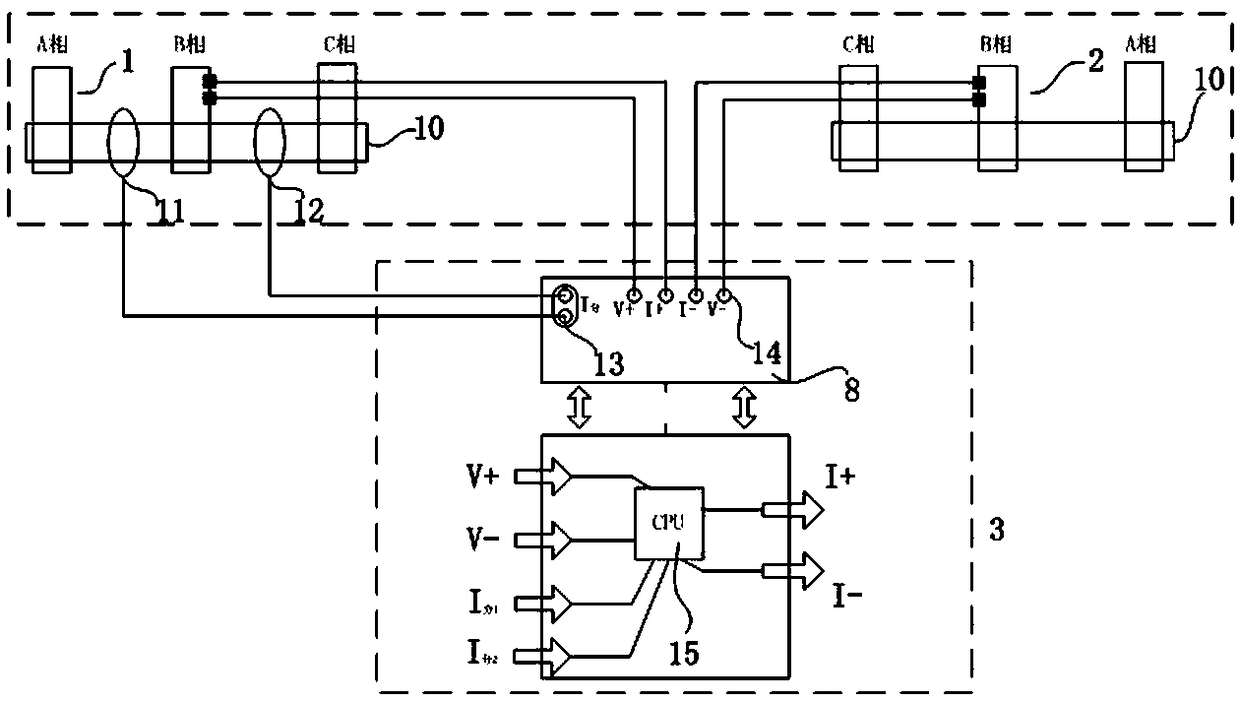

[0036] Such as figure 2 Shown is the second embodiment of the GIS loop resistance testing device and method without dismantling the grounding bar of the present invention. This embodiment is similar to the first embodiment, the difference is that the first grounding bar 1, the second The ground bars 2 each include a phase A ground bar, a B phase ground bar, and a C phase ground bar, and the A phase ground bar, the B phase ground bar, and the C phase ground bar are connected in series through copper pieces 10, so The copper part 10 is grounded; the Hall element 9 includes a first Hall element 11 and a second Hall element 12, and the first Hall element 11 is arranged between the A-phase ground row and the B-phase ground row The second Hall element 12 is arranged on the copper piece 10 between the B-phase ground bar and the C-phase ground bar.

[0037] When testing the B-phase loop resistance, the specific implementation of the present embodiment is as follows:

[0038] S1. Di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com