Position Error Compensation Method for Coreless Current Sensor

A current sensor and error compensation technology, which is applied in the field of position error compensation method, can solve problems such as troublesome industrial applications, complex and variable positional relationship between current-carrying wires and sensors, and achieve the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

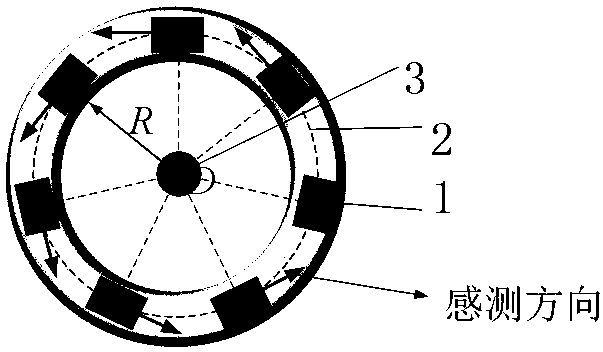

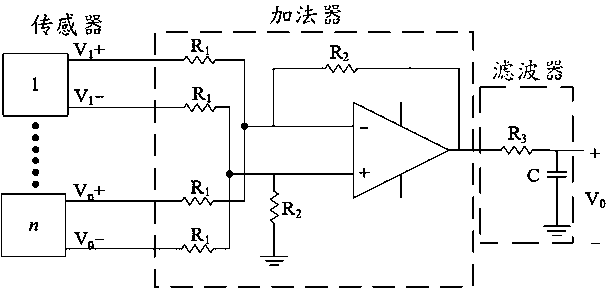

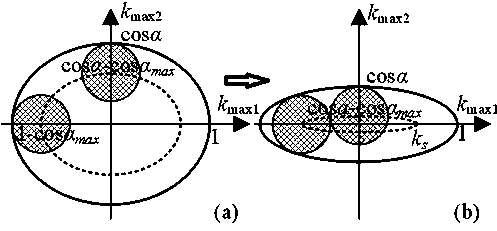

[0021] A position error compensation method for a coreless current sensor of the present invention arranges a plurality of magnetic field sensors without a magnetic core evenly on a circular printed circuit board (similar to an ampere ring), and by proportionalizing the magnetic field values sensed by each sensor Weighting reduces the measurement error caused by the positional relationship, and changes the proportional relationship between the inner diameter of the ring in the sensor array and the diameter of the current-carrying conductor in the design, so that the designed sensor can meet the accuracy requirements. Specifically include the following steps: including the following steps: Step S1: uniformly install n magnetic field sensors without magnetic cores on a circular printed circuit board, the sensing direction of the n magnetic field...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com