Mask plate, production method thereof, display substrate, packaging method thereof and display device

A technology for display substrates and manufacturing methods, which is applied in the field of mask plates, can solve problems such as the influence of display device packaging effects and thickness, and achieve the effect of meeting design requirements and ensuring packaging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

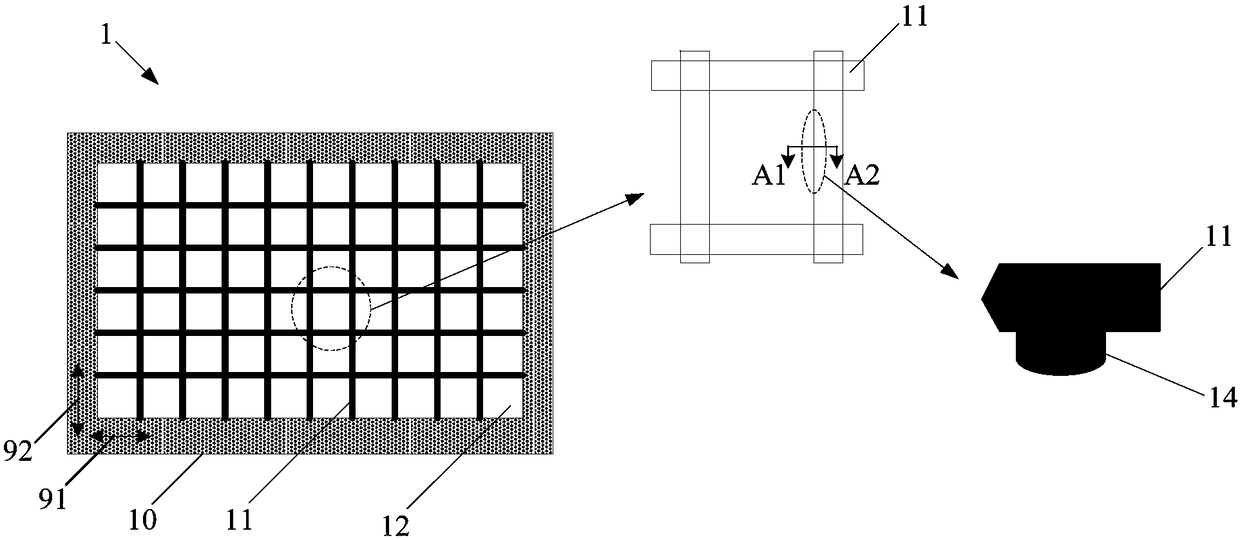

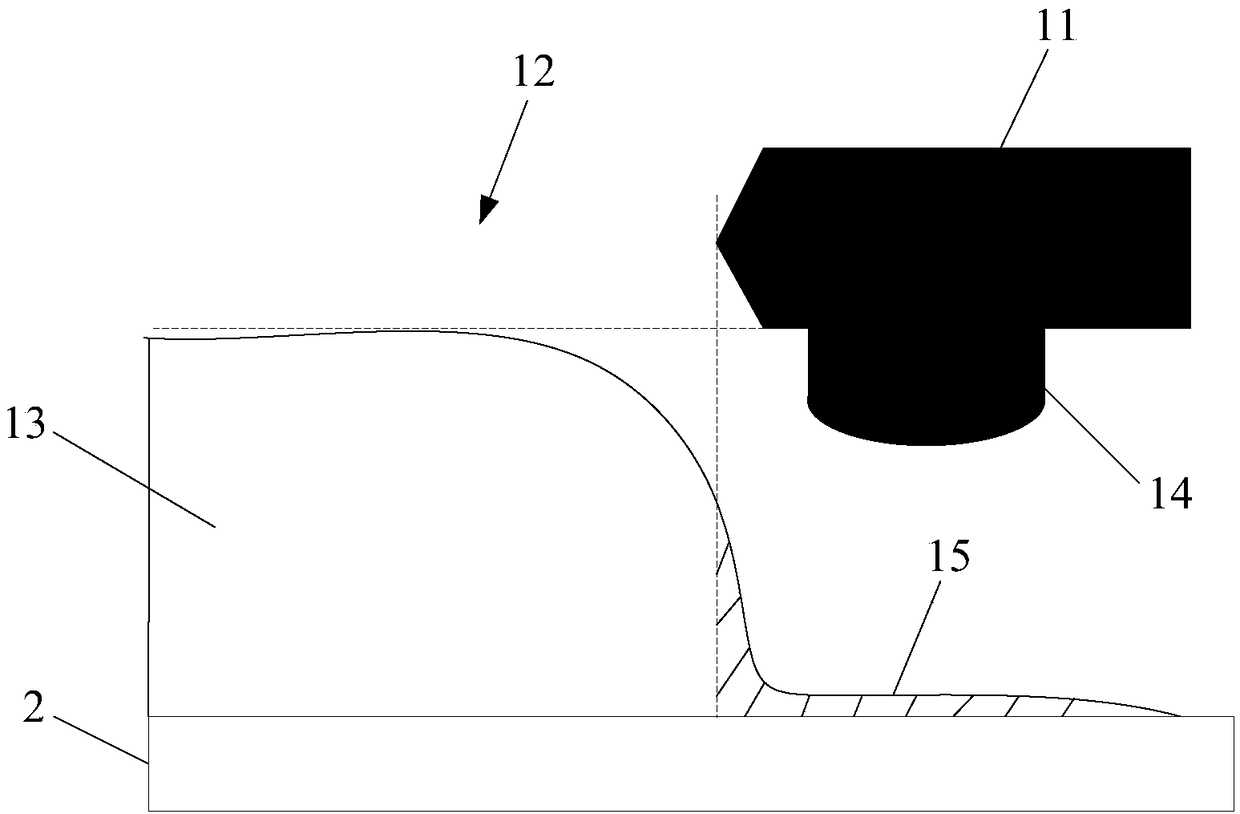

[0055] In order to further illustrate the mask plate and its manufacturing method, the display substrate and its packaging method, and the display device provided by the embodiments of the present invention, a detailed description will be given below in conjunction with the accompanying drawings.

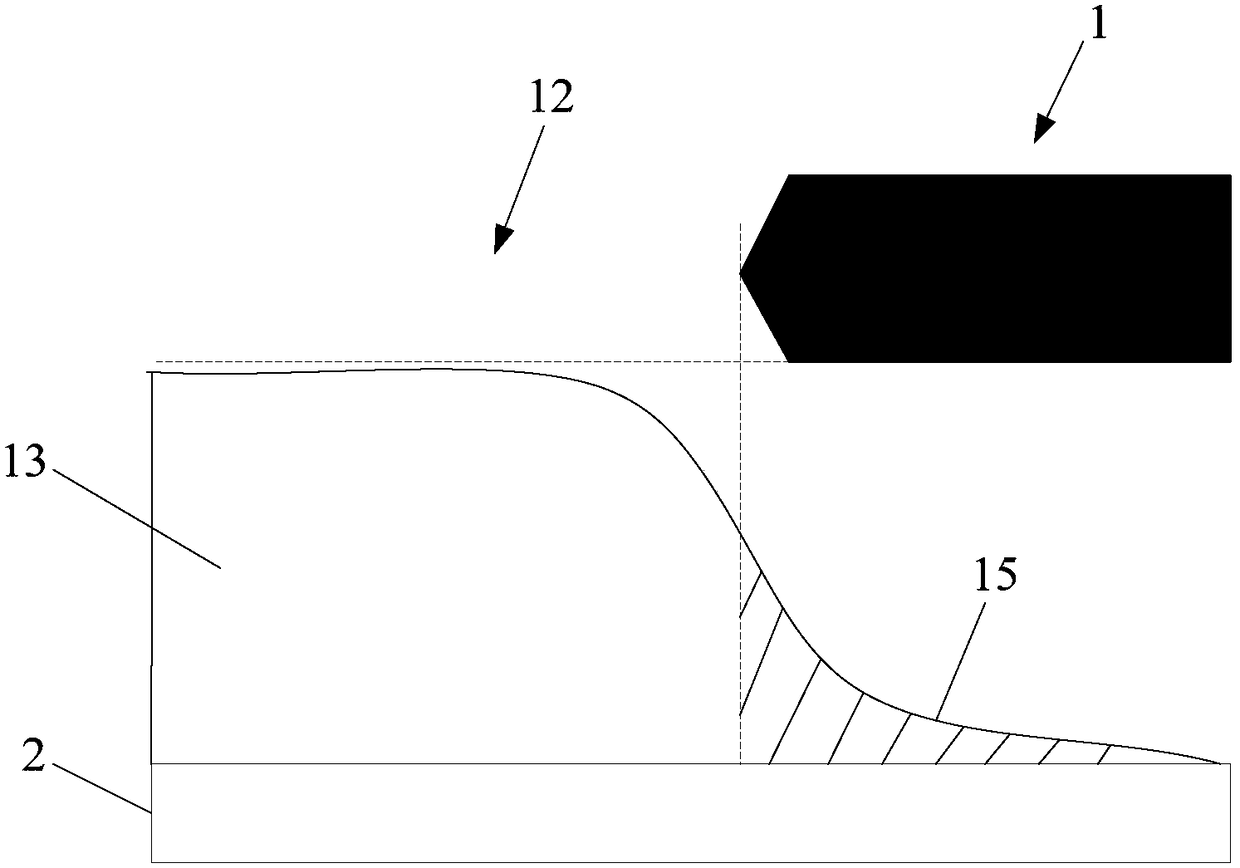

[0056] As described in the background art, see figure 1 , in the prior art, when the display device is packaged, the Under Coating15 will be formed on the motherboard 2 of the display device that is covered by the non-opening area of the mask plate 1, and the coverage of the Under Coating15 is from the mask plate 1 Starting from the edge of the opening of the opening, extending to the edge of the display device corresponding to the opening, and from the edge of the opening to the edge of the display device, the thickness of Under Coating15 is gradually reduced; once the thickness of UnderCoating15 at the edge of the display device When it is too thick, it is easy to cause cracks i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com