Lithium ion battery formation hydrojet-proof device

A lithium-ion battery and blowout prevention technology, which is applied to transfer electrolyte devices, secondary batteries, electrochemical generators, etc., can solve the problems of poor battery weight consistency, environmental pollution, production troubles, etc., and achieves simple structure, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other; the present invention will be described in detail below with reference to the accompanying drawings and in combination with the embodiments.

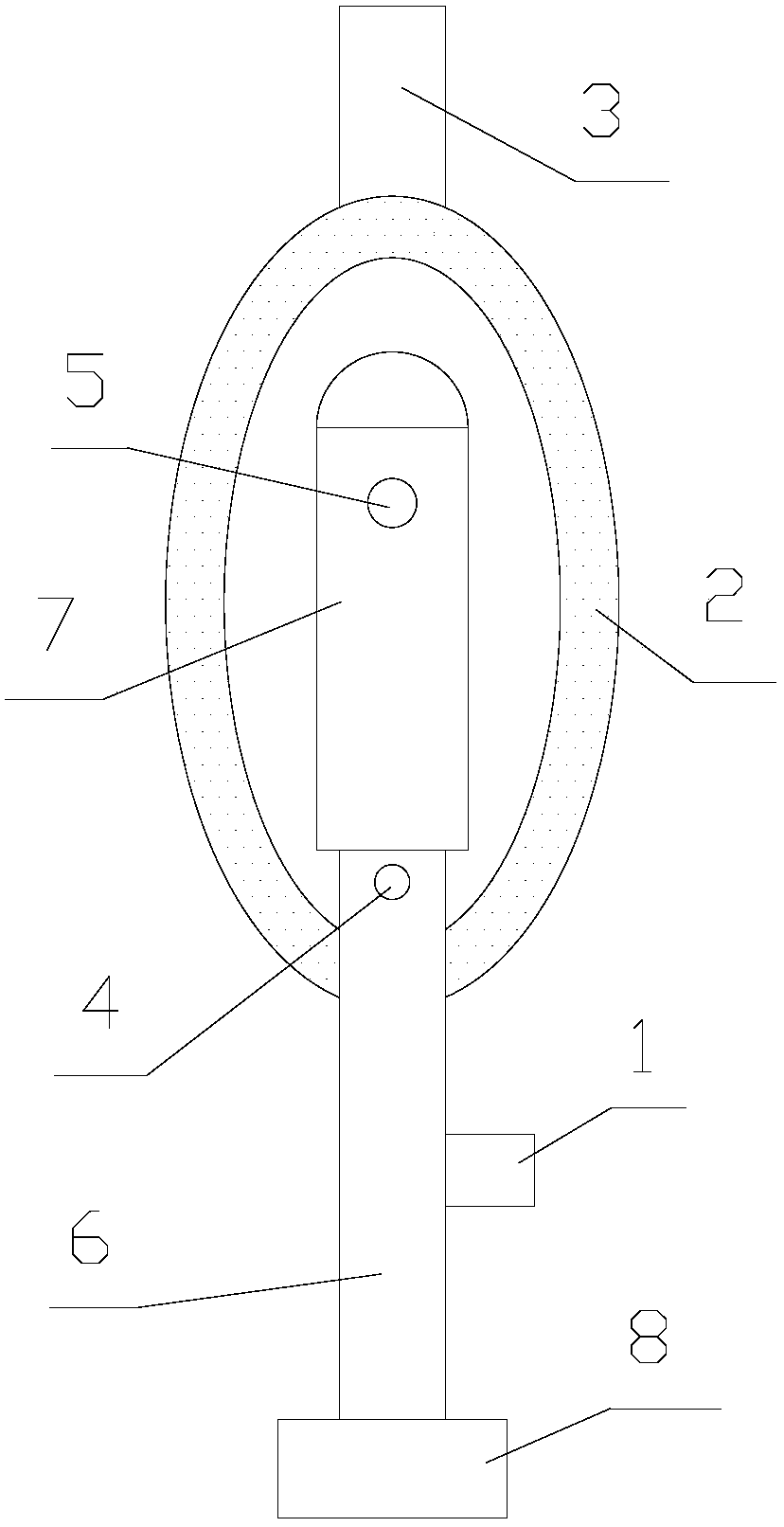

[0020] refer to figure 1 , 2 :

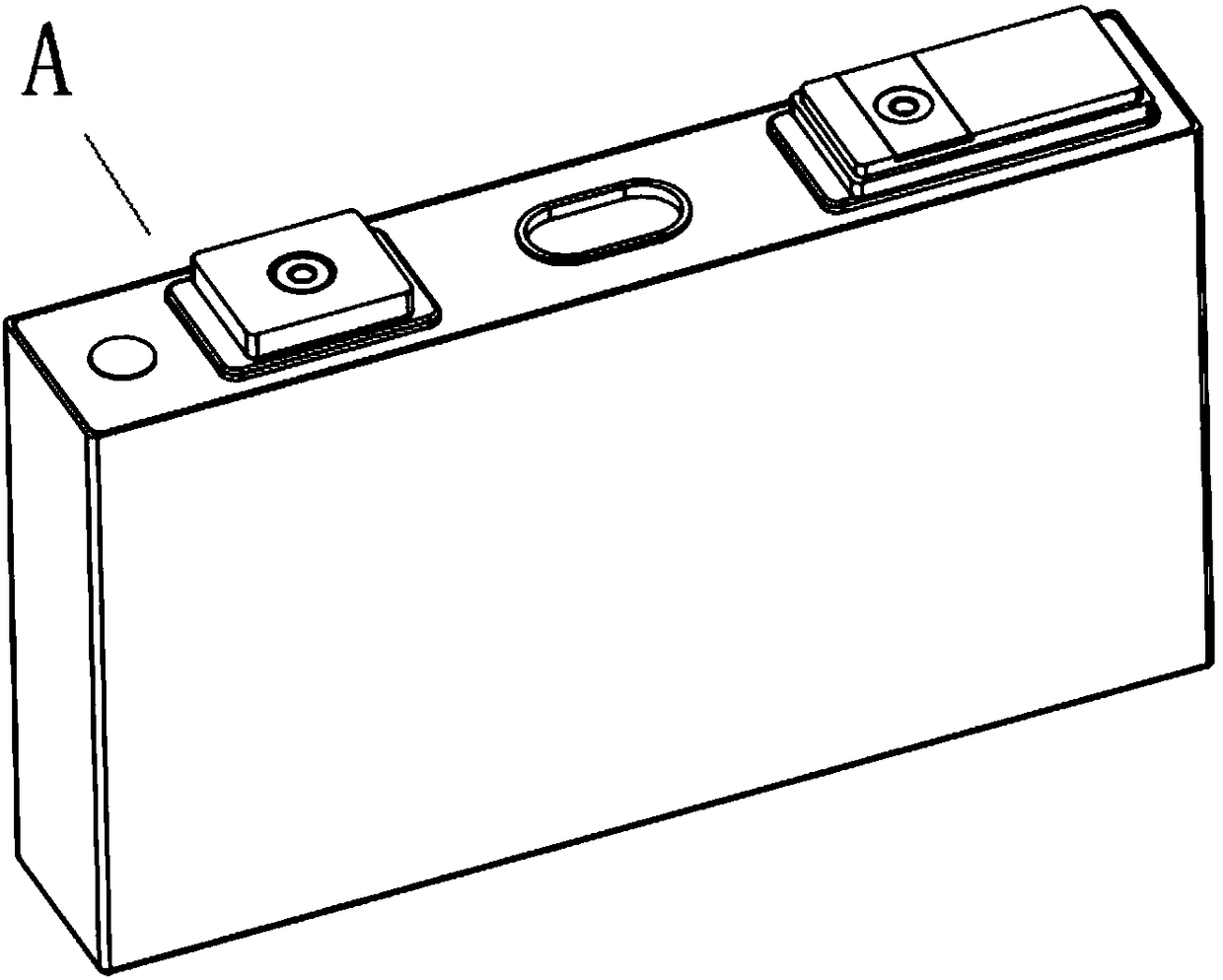

[0021] The present invention proposes a lithium-ion battery formation anti-spray device, comprising a connecting pipe assembly, a valve, a liquid accumulation chamber, and a connecting pipe. The first end of the connecting pipe assembly is located outside the liquid accumulation chamber, and the second end of the connecting pipe assembly is Located in the effusion cavity, the first end of the connecting tube assembly is open, and the second end of the connecting tube assembly is closed; the connecting tube assembly is provided with a return hole and a drain hole, both of which are located in the effusion cavity Inside, the drain hole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com