Planar separated motor applied to wall breaking machine

A plane separation and wall breaking machine technology, which is applied in applications, electromechanical devices, electrical components, etc., can solve the problems of inconvenient placement and taking of the mixing cup, loud working noise, and short life of the motor, so as to achieve convenient cleaning and prolong The effect of long service life and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be described below in conjunction with the drawings and embodiments.

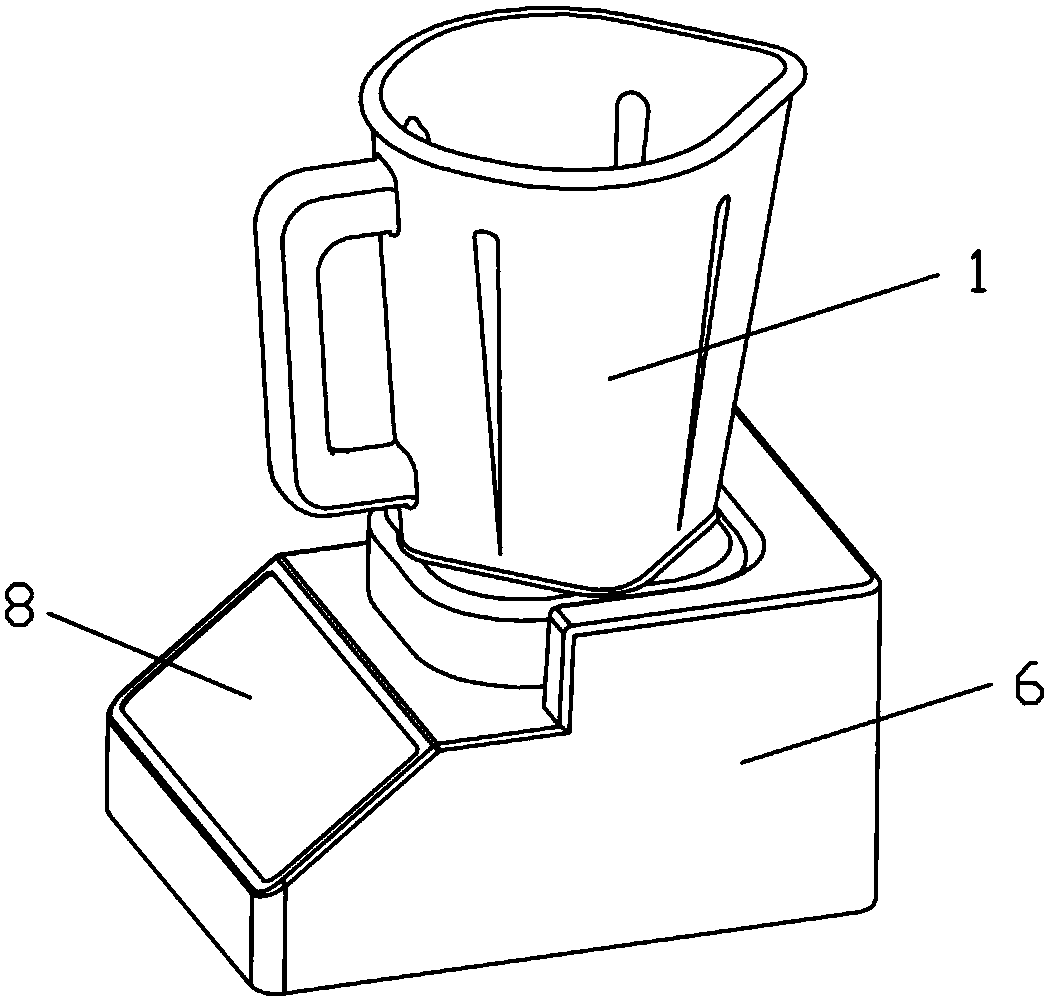

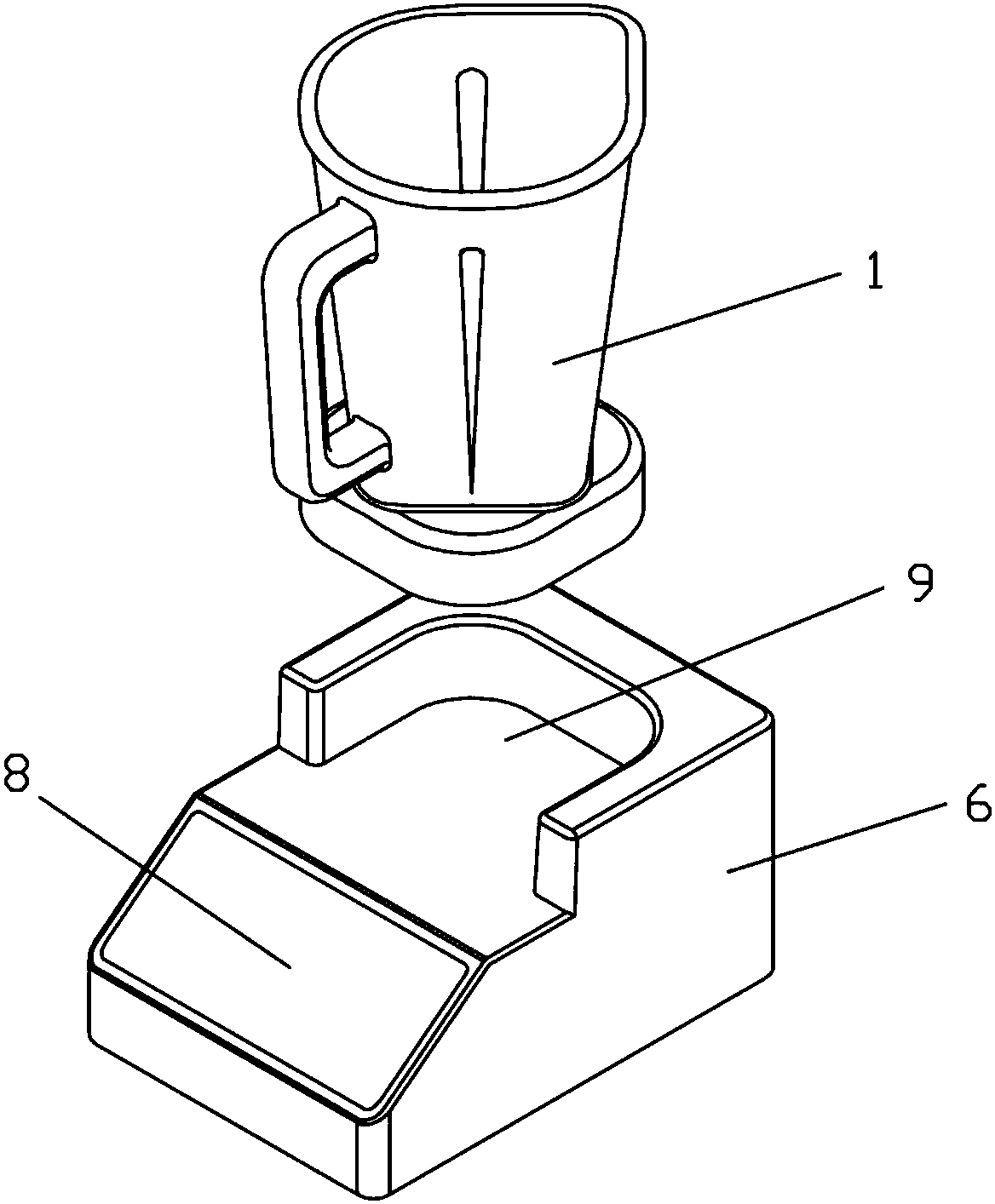

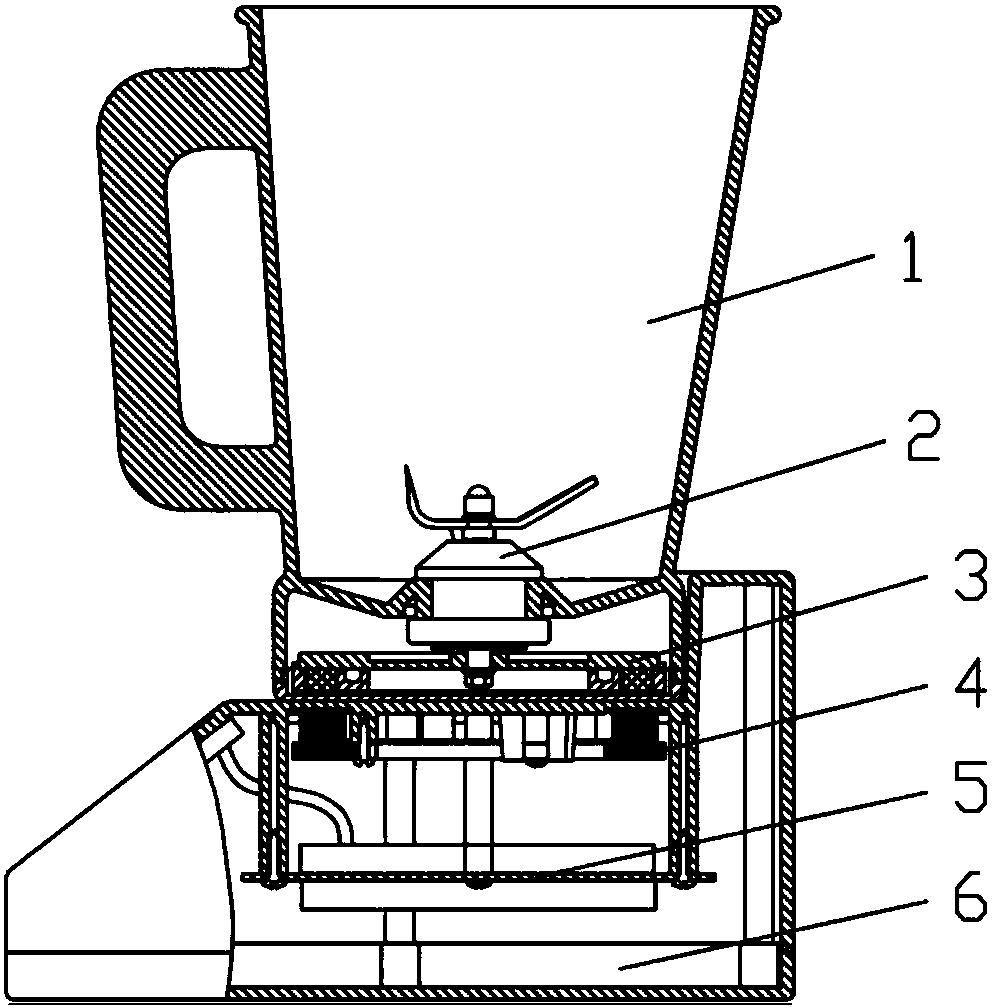

[0027] Such as Figure 1 to Figure 3 As shown, a planar split motor applied to a wall breaking machine according to the present invention includes a planar split motor rotor 3 and a planar split motor stator 4, and the planar split motor rotor 3 is arranged on the stirring cup 1 of the wall breaking machine In the cavity at the bottom, and connected with the cutter head part 2 in the mixing cup 1 through a shaft, the plane separated motor stator 4 is set in the cavity of the base 6 of the wall breaker, and is connected with the base 6 The system control part 5 is electrically connected, the bottom of the stirring cup 1 is fixed with a cup bottom cover 7, and the top of the base 6 is provided with a U-shaped seat 9, and the cup bottom cover 7 can be pushed in and taken out from the U-shaped seat 9 in the horizontal direction to realize plane separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com