Disk-type double-support double-stator permanent magnetic synchronous traction machine

A synchronous traction machine, double support technology, applied in the direction of electromechanical devices, control mechanical energy, magnetic circuit static parts, etc., can solve the problems of increasing the volume of the traction machine, the bending deformation of the shaft, the overall structure is not too compact, etc. Effects of Power Density and Traction Capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

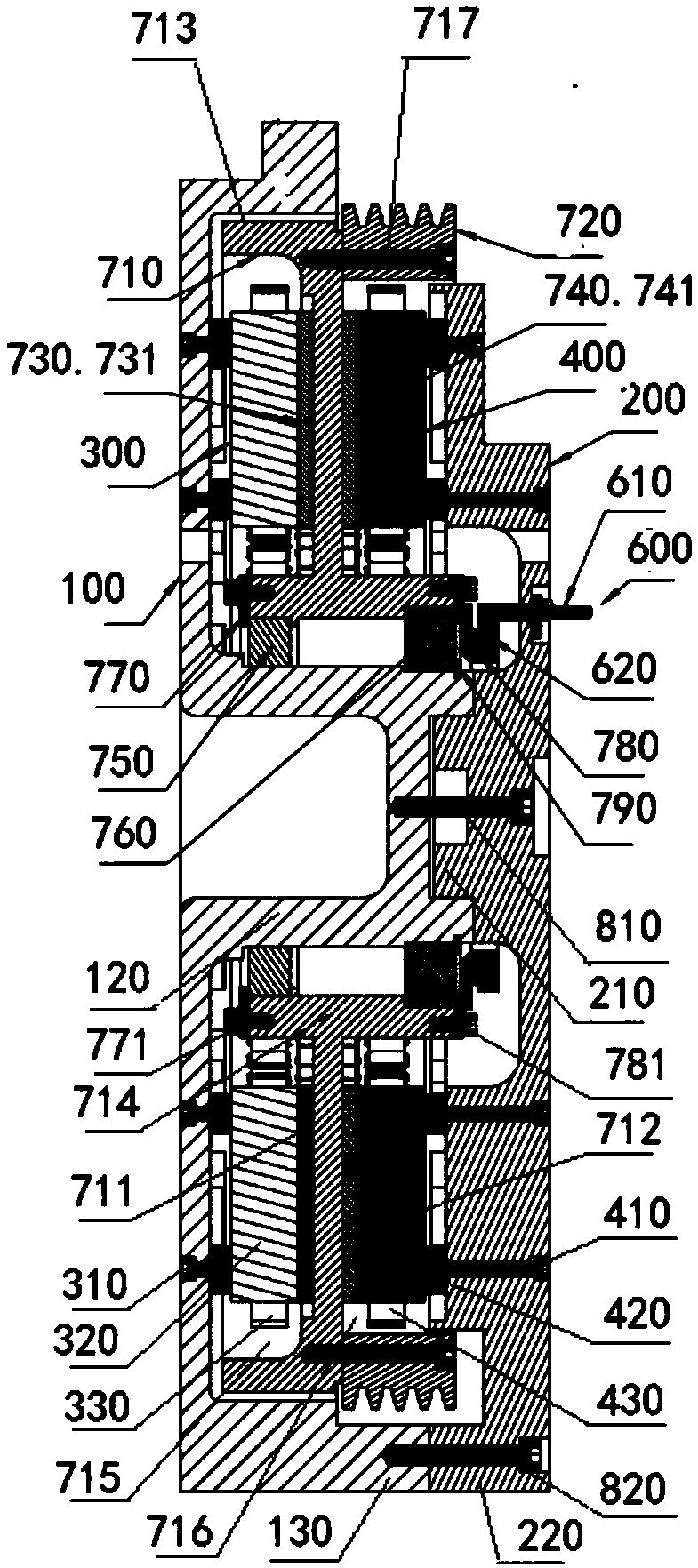

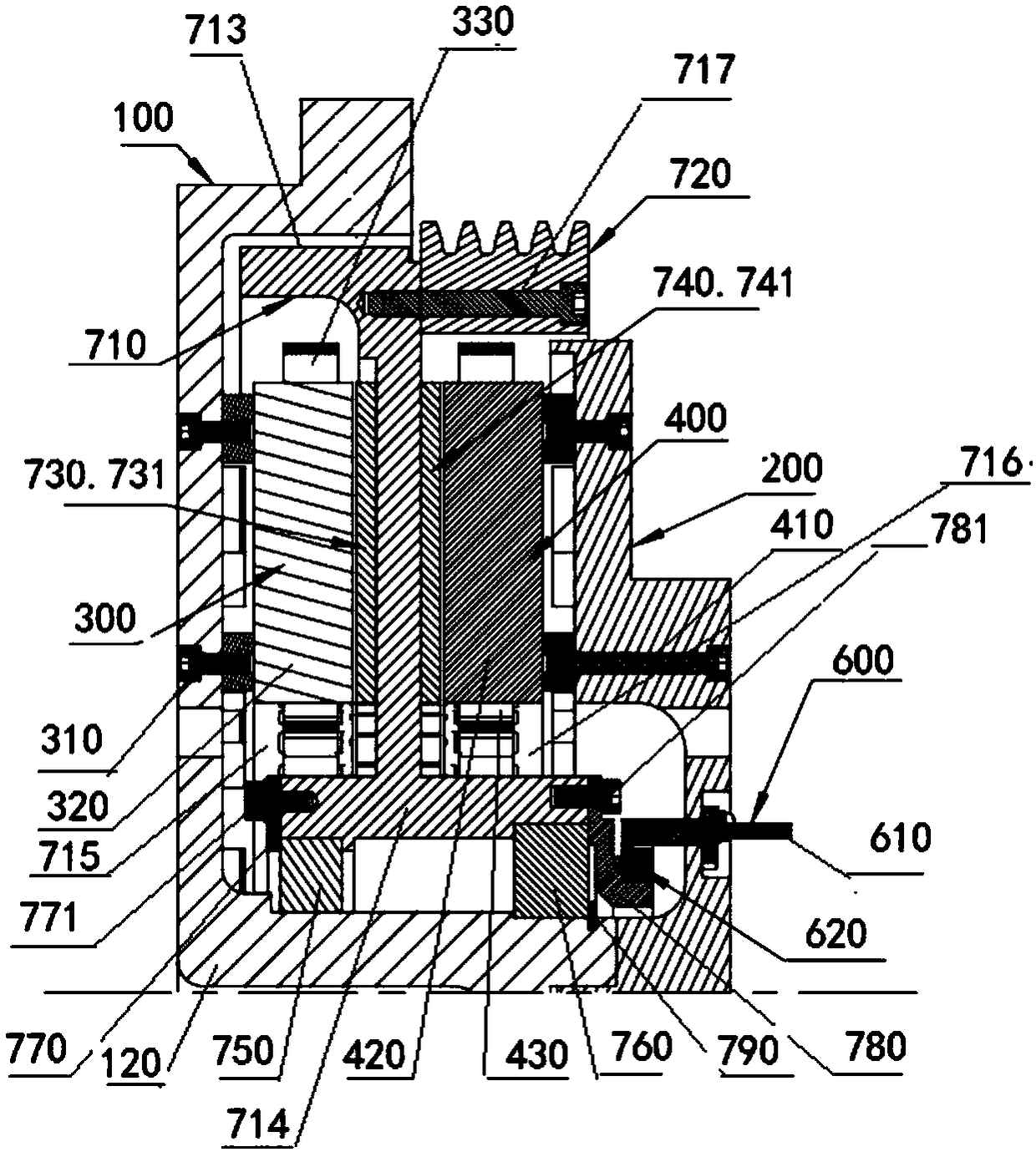

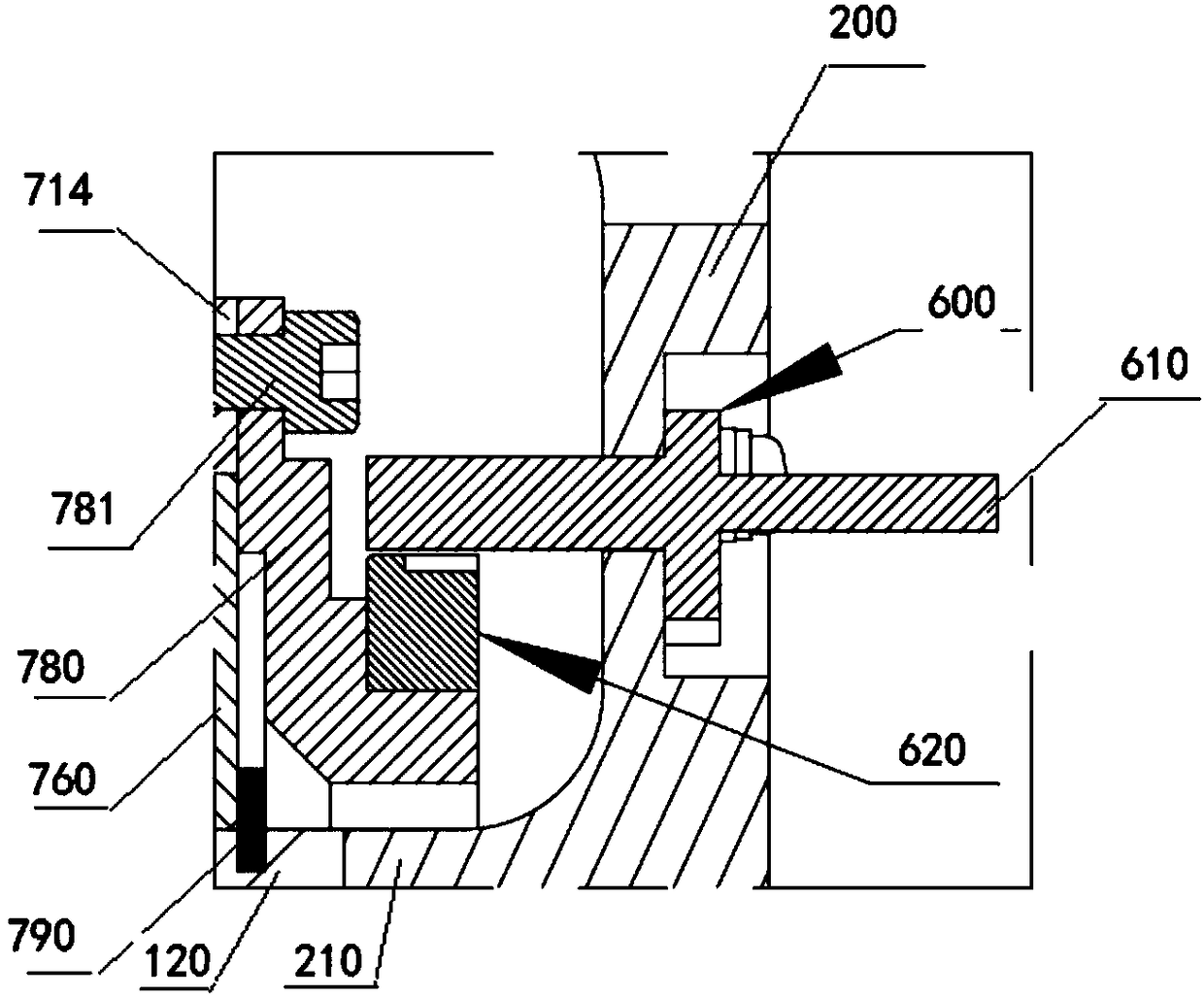

[0036] see Figure 1 to Figure 16 , the disc-type double-support double-stator permanent magnet synchronous traction machine shown in the figure consists of a first housing 100, a second housing 200, a first stator assembly 300, a second stator assembly 400, a rotor assembly, and a brake 500 , Encoder 600 and so on.

[0037] A first axially protruding central mounting portion 120 and a first axially protruding peripheral mounting portion 130 are disposed on the first housing 100 .

[0038] A second axially protruding central mounting portion 210 and a second axially protruding peripheral mounting portion 220 are disposed on the second housing 200 .

[0039] In this embodiment, the first stator assembly 300 is fixedly installed on the correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com