Universal PTC liquid heater

A technology of liquid heaters and heating cores, applied in the shape of heating elements, immersion heating devices, etc., can solve the problems of the increase in the breakdown ratio of PTC ceramics, and achieve the effects of beautiful appearance, easy installation, and easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

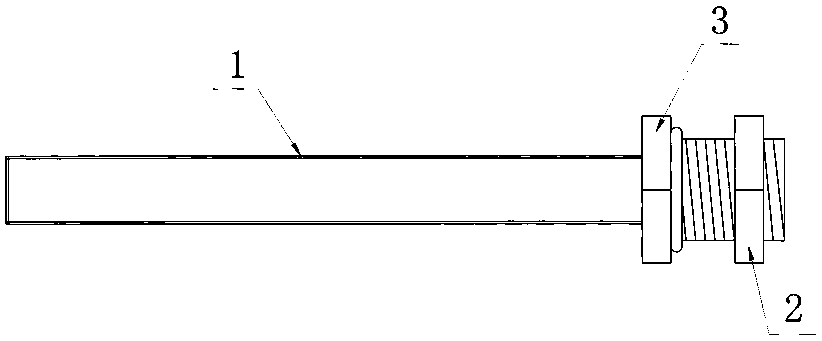

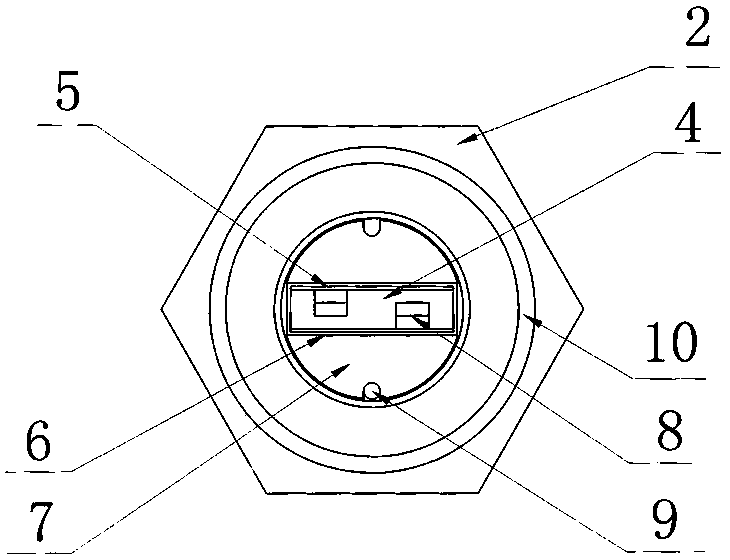

[0012] as attached figure 1 , figure 2 As shown, a general-purpose PTC liquid heater includes a circular tubular stainless steel shell 1, a PTC heating core and a sealing flange 3. One end of the stainless steel shell 1 in contact with water is welded and sealed, and the other end is installed with a sealing flange. The sealing method The blue is made of stainless steel, with a sealing ring 10, a screw port and an outer hexagonal nut 2 on the outside, and a hole inside, and the diameter of the hole matches the outer diameter of the required metal casing after shrinking; the stainless steel casing 1 is sealed by a sealing method The flanges are sealed with high temperature resistant epoxy resin. The PTC heating core 2 is set in the stainless steel shell 1, the PTC heating core 2 includes a PTC heating element 4, an electrode sheet 5 and an insulating film 6, and the PTC heating element 4 is composed of one or more pieces of special high temperature, high pressure The PTC cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com