Cutting saw intermittent work mounting support

A technology for installing brackets and cutting saws, which is applied to sawing machine devices, manufacturing tools, metal sawing equipment, etc., can solve the problems of increased production costs, large distances, and high maintenance costs, and achieves low production costs, easy cutting, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

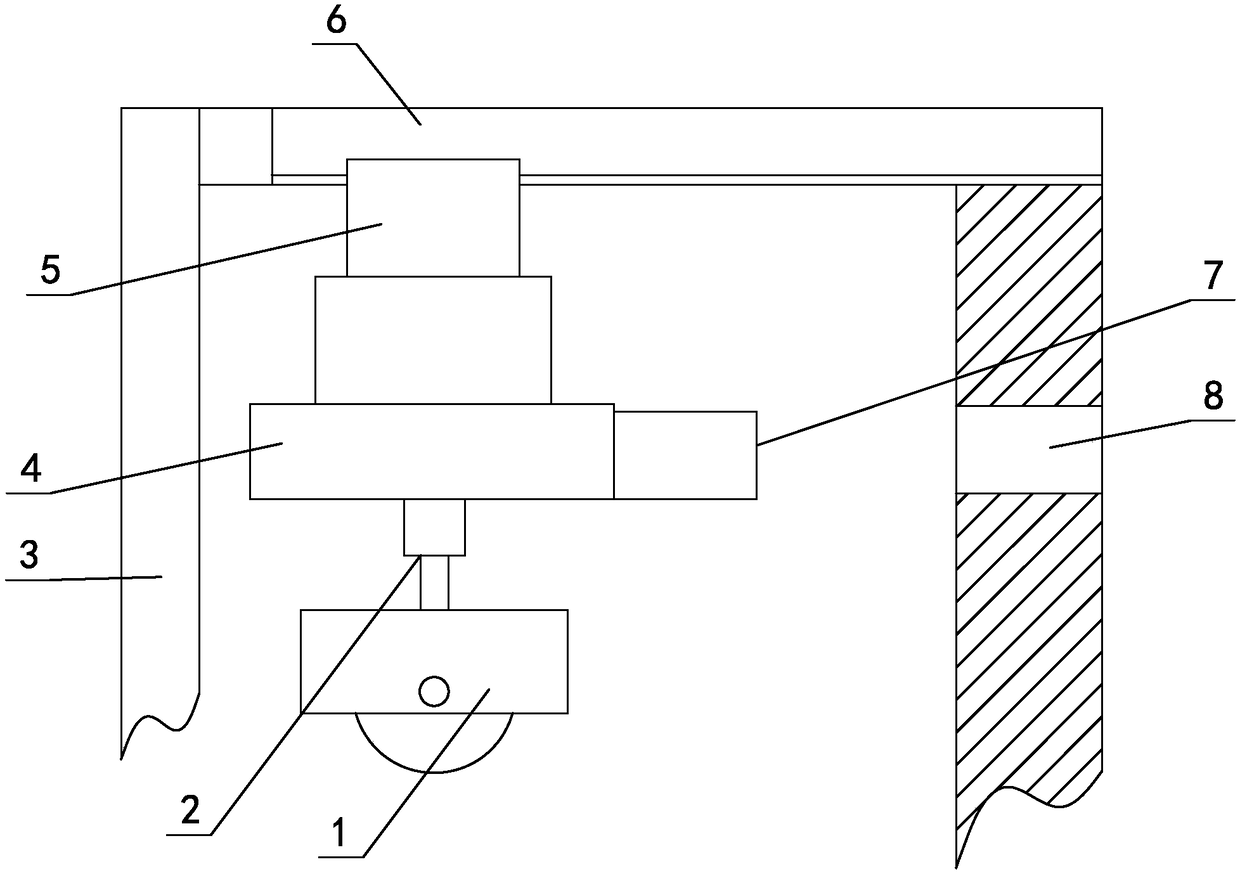

[0015] As shown, the cutting saw intermittent work installation bracket includes a gantry bracket 3, a slide rail 6 is installed horizontally on the gantry bracket 3, a slide block 5 is installed on the slide rail 6, and a mounting plate is horizontally fixed at the bottom of the slide block 5 4. The right side of the mounting plate 4 is provided with a locking pin 7 horizontally to the right. The corresponding locking pin 7 is provided with a pin hole 8 for the locking pin 7 on the support leg on the right side of the gantry bracket 3, and is vertically mounted on the bottom of the mounting plate 4. Hydraulic cylinder 2 is installed.

[0016] In this embodiment, the sliding block 5 is equipped with a driving mechanism that slides left and right along the slide rail 6 .

[0017] When installing, set the product conveyor along the right side of the cutting saw 1. When cutting, the driving mechanism drives the mounting plate 4 to move to the right, so that the locking pin 7 is i...

Embodiment 2

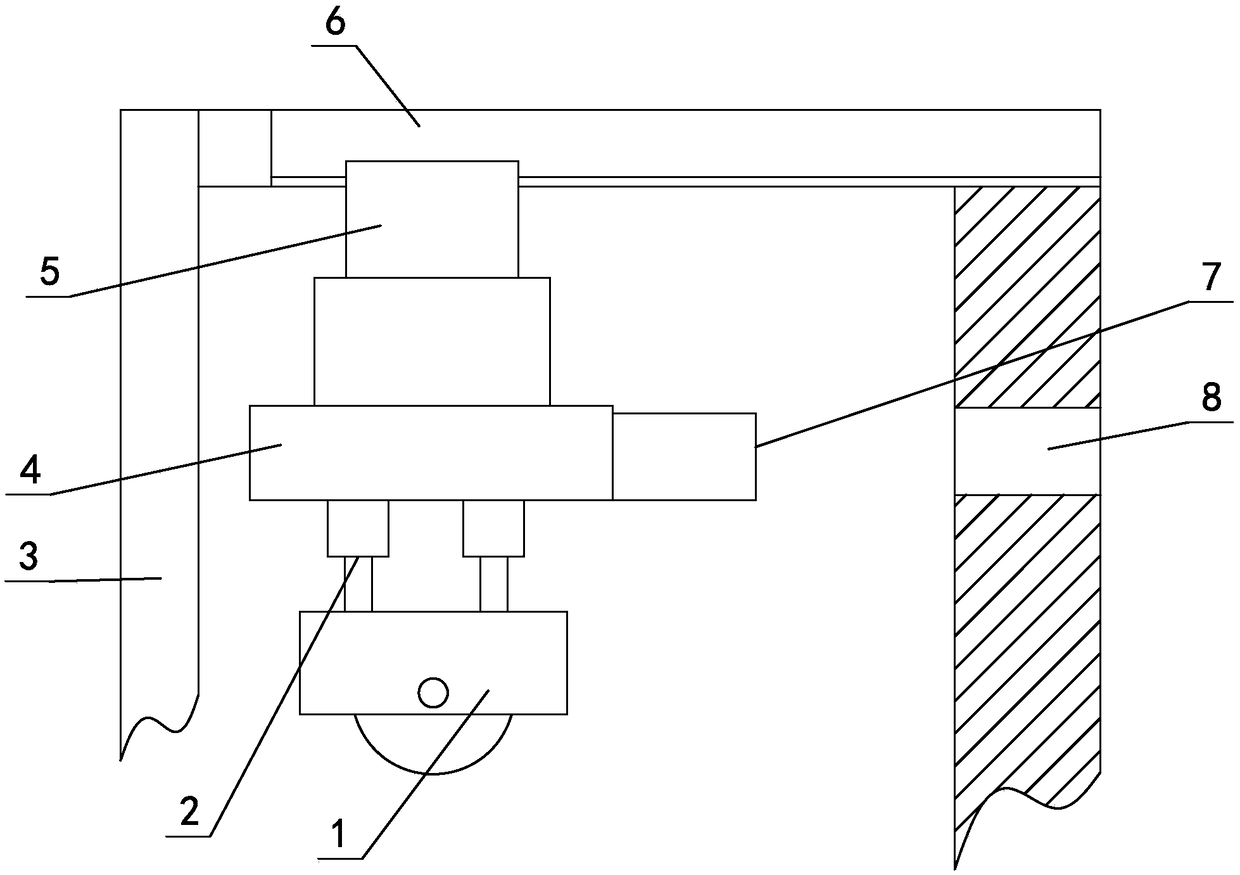

[0019] Changes are made on the basis of Example 1, such as figure 2 As shown, there are two hydraulic cylinders 2, which are distributed parallel to the left and right, so as to further improve the stability during cutting.

[0020] Others are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com