Cut-off device and method for plastic composite packaging bag bag-making

A composite packaging bag and cutting device technology, which is applied in the field of packaging bag production, can solve the problems of high equipment cost, reduced work efficiency, and complex overall device, and achieve the effects of reducing production cost, improving work efficiency, and reducing wear frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

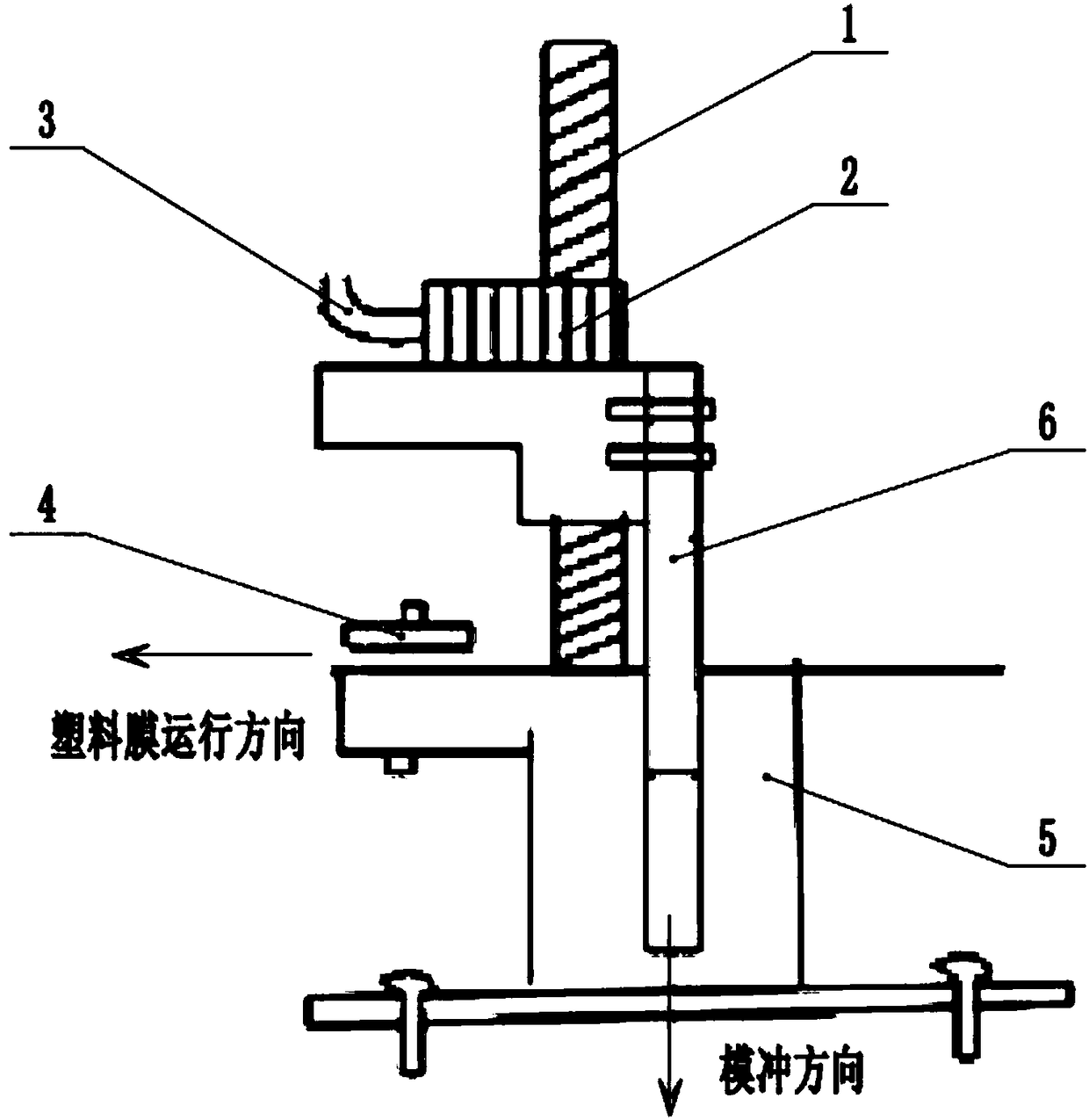

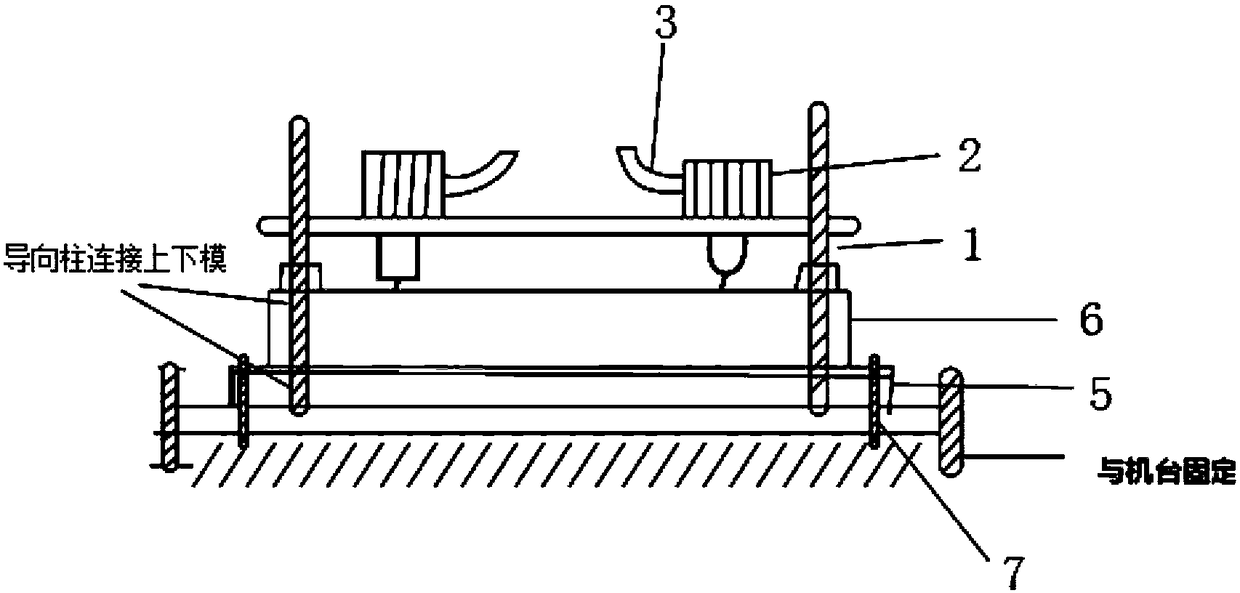

[0033] A plastic composite packaging bag making and cutting device, comprising, an upper convex mold and a lower concave mold, the punching width of the upper convex mold and the lower concave mold is 2 mm, and the upper convex mold is equipped with a forward air pump and a reverse air pump To provide power, the two air pipes of the forward air pump and the reverse air pump are connected with a solenoid valve controlled by the bag making machine. Both ends of the upper punch are equipped with upper and lower guide posts to fix the running direction of the die cutter.

[0034] The die cutter is vertically fixed to the machine table. The specific fixing method is that there is a screw hole on the die cutter, and the die cutter is fixed to the corresponding position on the machine table by bolt connection. Loosen the bolt and it can be removed from the machine table to release the electrical connection. , The die cutter is lifted along the guide column, and the upper and lower die cu...

Embodiment 2

[0037] The difference between Example 2 and Example 1 is that the length of the die cutter in Example 2 is 500 mm, which is suitable for punching plastic composite packaging bags of various materials, various thicknesses and widths.

[0038] From the above description, it can be seen that the above-mentioned embodiments of the present application achieve the following technical effects:

[0039] 1) One cut for each cut, making full use of the cutting edge of the cutter, reducing redundant actions and improving work efficiency;

[0040] 2) Since the "single cutter" is used in this application, the wear frequency is reduced compared with the traditional technology, and the tool is not easy to curl and wear, which reduces the production cost. In particular, the plastic bags produced by our company are composite materials, which are generally thicker and have a large number of materials composited with aluminum foil. The punching effect is significantly better than that of the "double cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com