A plate positioning and grabbing system and positioning and grabbing method applied to an automated production line

An automatic production line and plate technology, applied in positioning devices, metal processing equipment, feeding devices, etc., can solve problems such as poor positioning accuracy, positioning accuracy dependent on positioning accuracy, life-threatening, etc., to achieve rapid action response, high positioning accuracy, good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The plate positioning and grasping system and positioning and grasping method applied to the automatic production line of the present application are preferably applied to the precise positioning and grasping of parts before bending, and of course, can also be applied to other processes.

[0076] The precise positioning and grasping of parts before bending will be taken as a specific embodiment below to further describe the application in detail.

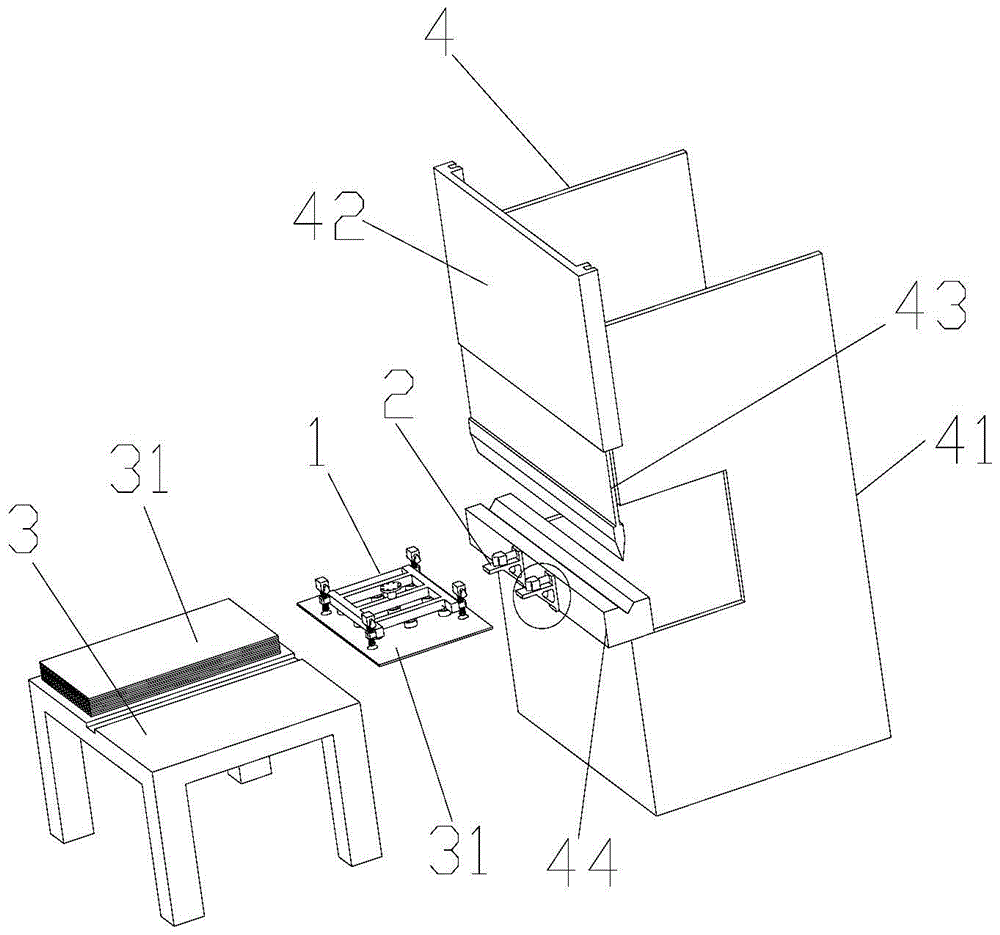

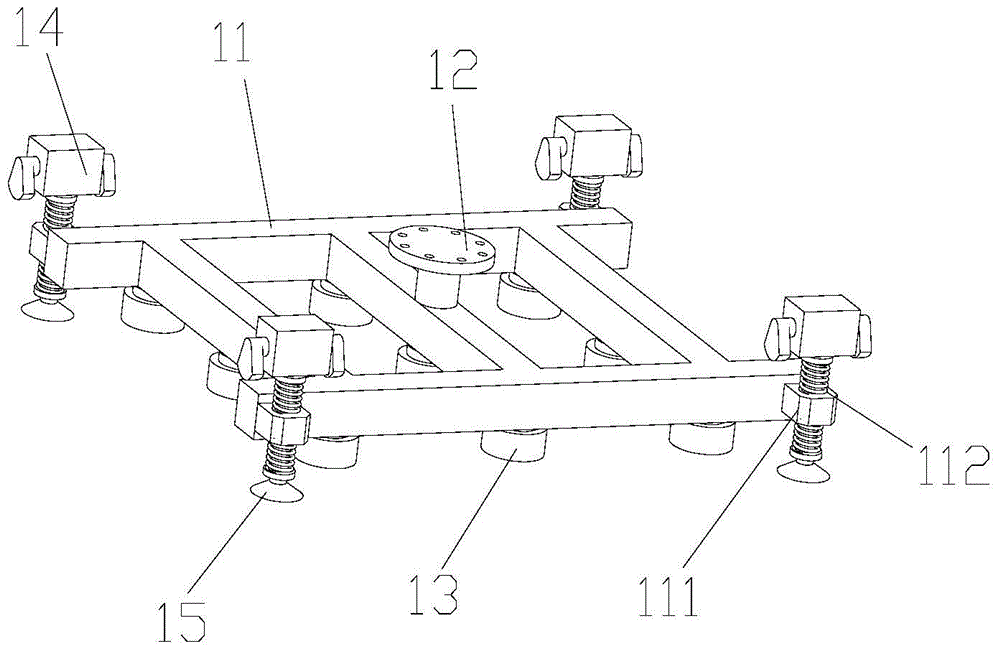

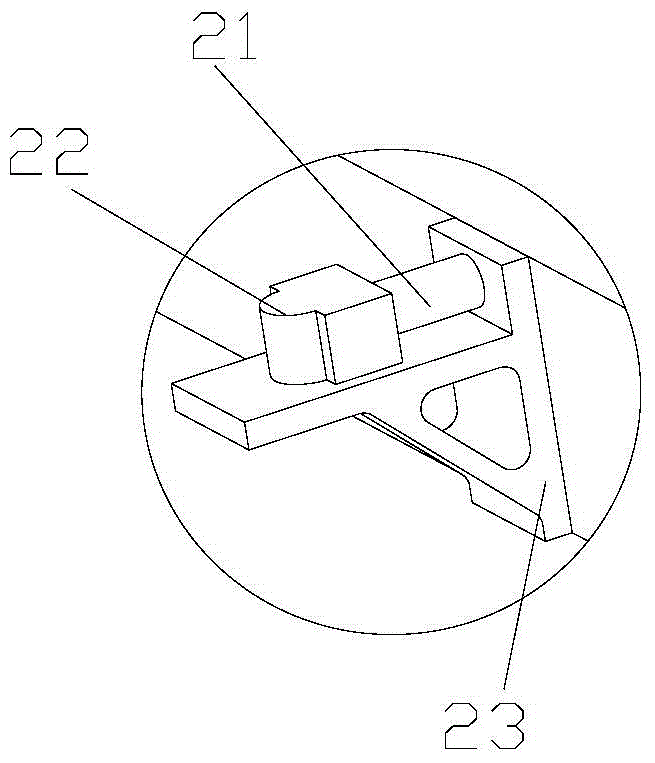

[0077] Such as figure 1 As shown, a plate positioning and grabbing system applied to an automated production line includes a manipulator, a material rack 3, a material picking gripper 1, at least two positioning devices 2, a bending machine 4 and a numerical control system.

[0078] Above-mentioned bending machine 4 is prior art, as figure 1 As shown, it includes a fuselage 41, a slider 42, an upper mold 43 and a lower mold 44. Wherein, the position of the lower mold 44 is fixed, that is, the positioning plate placement are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com