Automatic guided vehicle (AGV)

A technology of car body and lifting frame, applied in the field of AGV vehicles, can solve the problems that the structure of AGV vehicles needs to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] As can be seen from the background technology, the structure of the existing AGV car still needs to be improved.

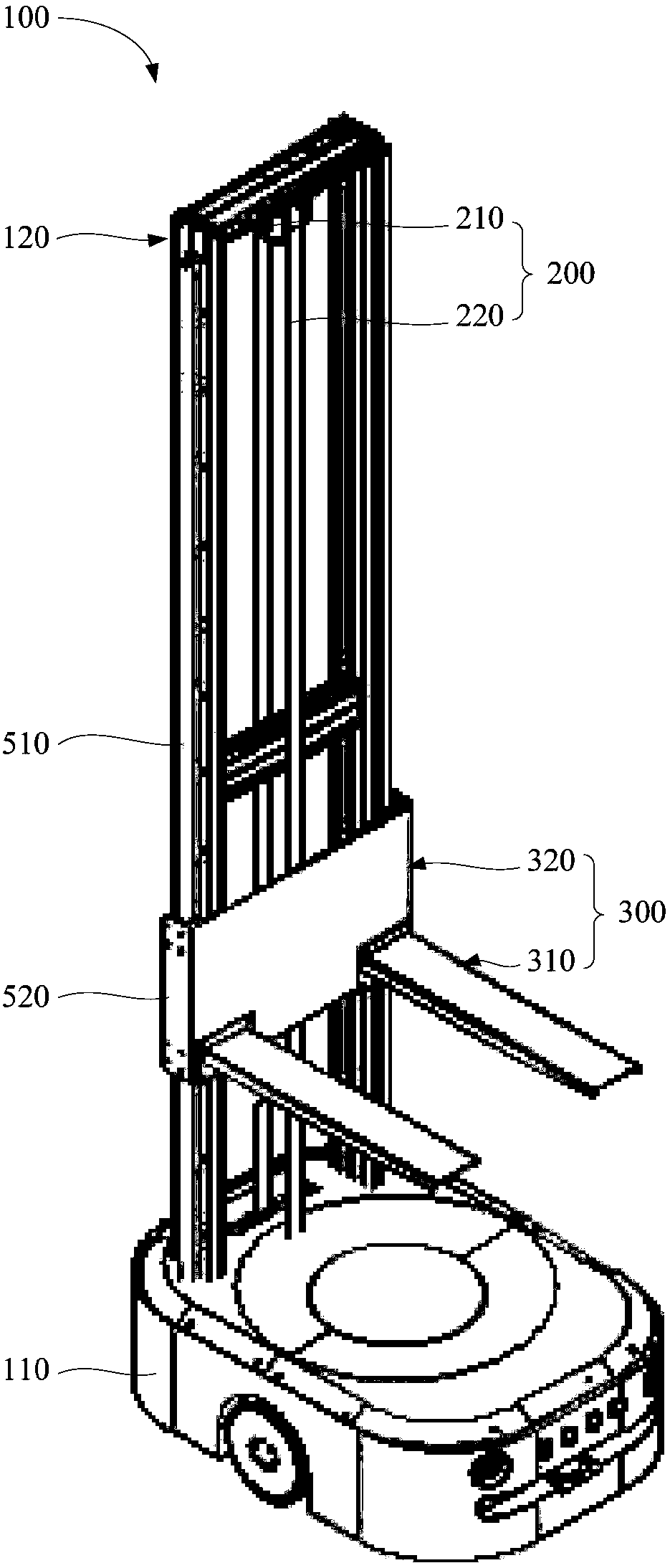

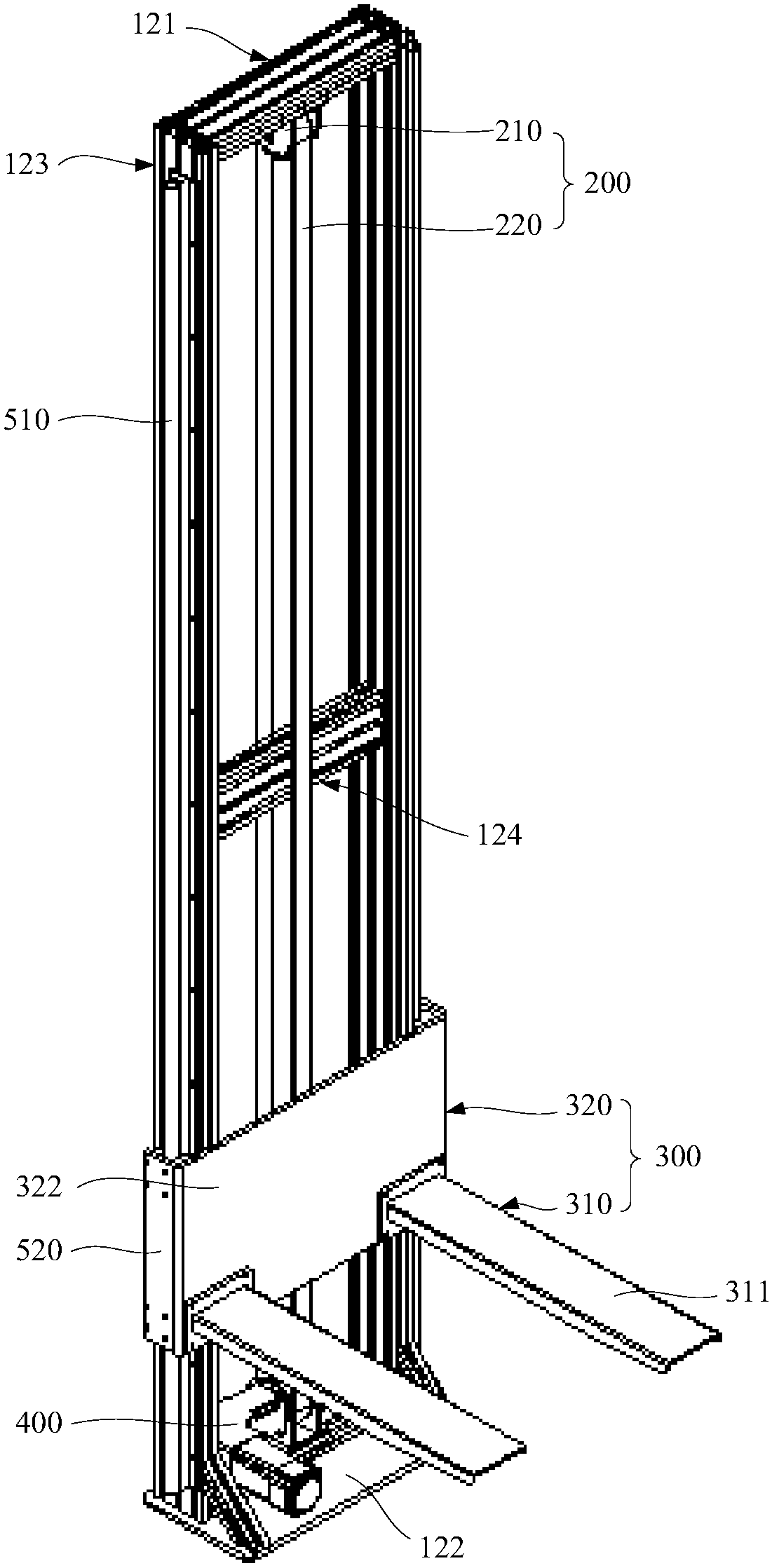

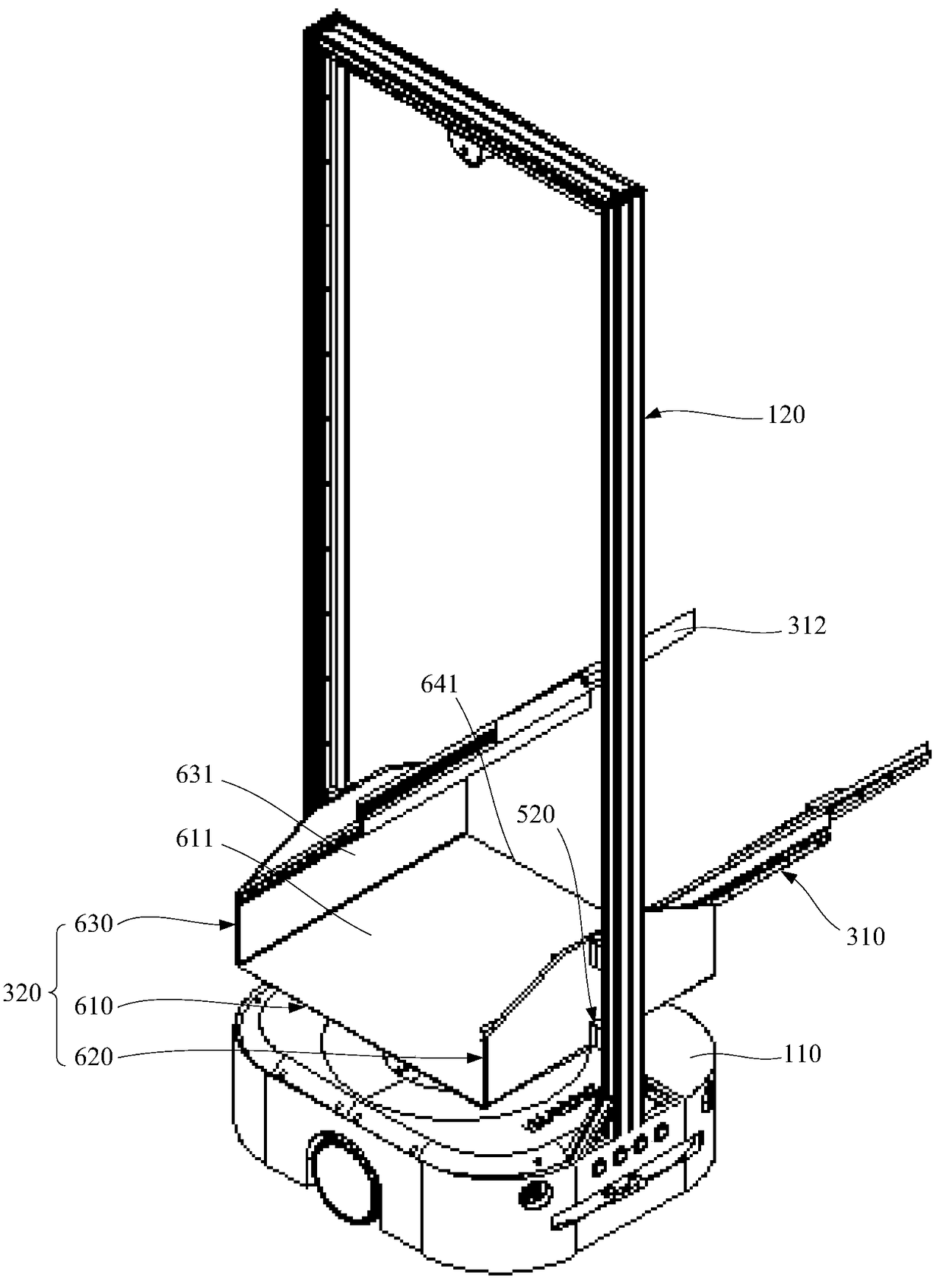

[0039] Now analyze in conjunction with an AGV car, the AGV car includes: a car body and a lifting frame arranged on the car body; two sprockets, each of which is respectively arranged on the top beam and the bottom beam On, the outer peripheral surface of the sprocket has sprocket teeth arranged at equal intervals along the circumferential direction of the sprocket; the chain, the chain is sleeved on the two sprockets, and the chain and the sprocket teeth The picking mechanism, the picking mechanism is fixed on the sprocket, and the moving of the sprocket drives the picking mechanism to rise or fall; the driving source, the driving source is suitable for driving the The sprocket rotates.

[0040] The above-mentioned AGV vehicles still need to be improved, and the reasons for this are as follows:

[0041] Relying on the meshing between the chain and the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com