Automatic pressing assembling device and method for spoiler

A technology for assembling equipment and assembling methods, which is applied in the direction of mechanical equipment, workpiece clamping devices, connecting components, etc., can solve the problems affecting the quality of the spoiler, labor time-consuming and labor-intensive consistency, etc., to achieve good assembly effect and strong product consistency , produce more effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

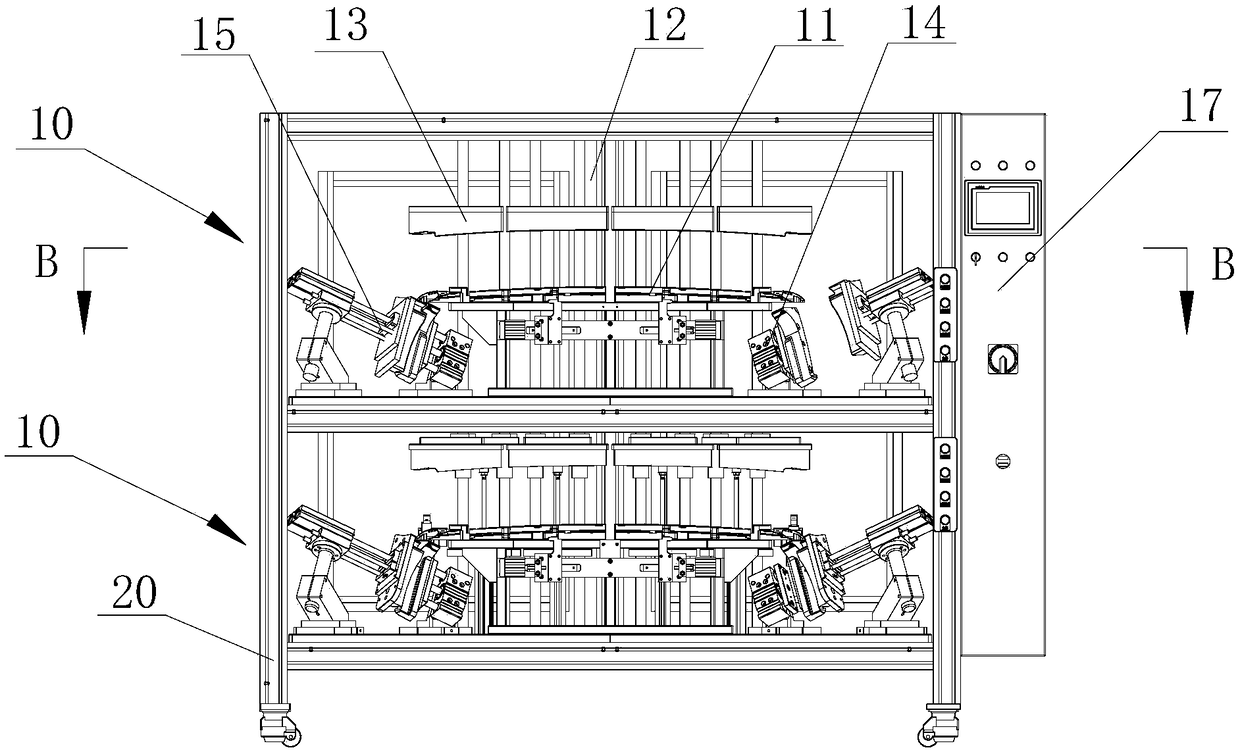

[0029] refer to figure 1 , in the figure, a spoiler automatic pressing and assembling equipment provided in this embodiment, which presses the spoiler after dispensing, makes the glue solidify and assembles the decorative board, and uses its automatic equipment to press Tight assembly reduces the labor intensity of workers, avoids consistency problems caused by manual operations by workers, and increases the reliability of the spoiler.

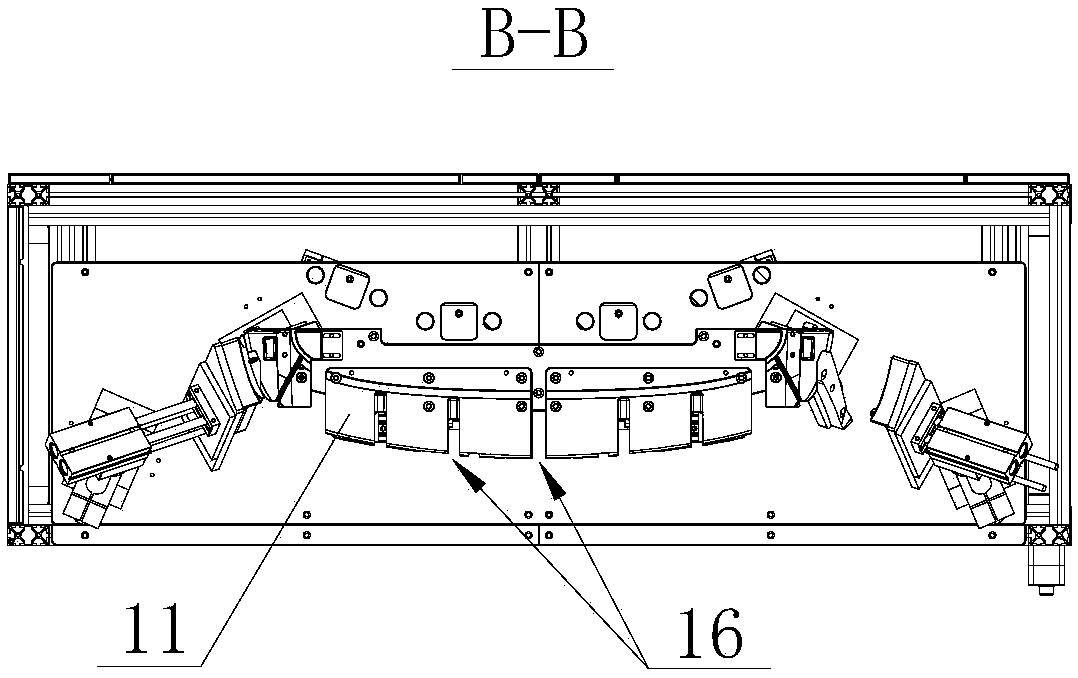

[0030] Specifically, the spoiler automatic pressing and assembling equipment includes a body 20 and a pressing device 10 in the body 20. The pressing device 10 includes a supporting mold 11, a middle pressing device, a two-side pressing device 14 and a decorative plate pressing device. Tightening device 15. After the spoiler is dispensed, the spoiler is placed on the support mold 11 by manual or mechanical means. The middle pressing device is arranged to be close to or away from the supporting mold 11 in the vertical direction. The two ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com