Torque-limited speed reducer

A technology of reducer and planetary reducer, which is applied to transmission parts, belts/chains/gears, mechanical equipment, etc. It can solve problems such as complex maintenance and repair, shutdown of working face, broken teeth of reducer, etc., to ensure continuous Work, save space, protect the effect of the motor and reducer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

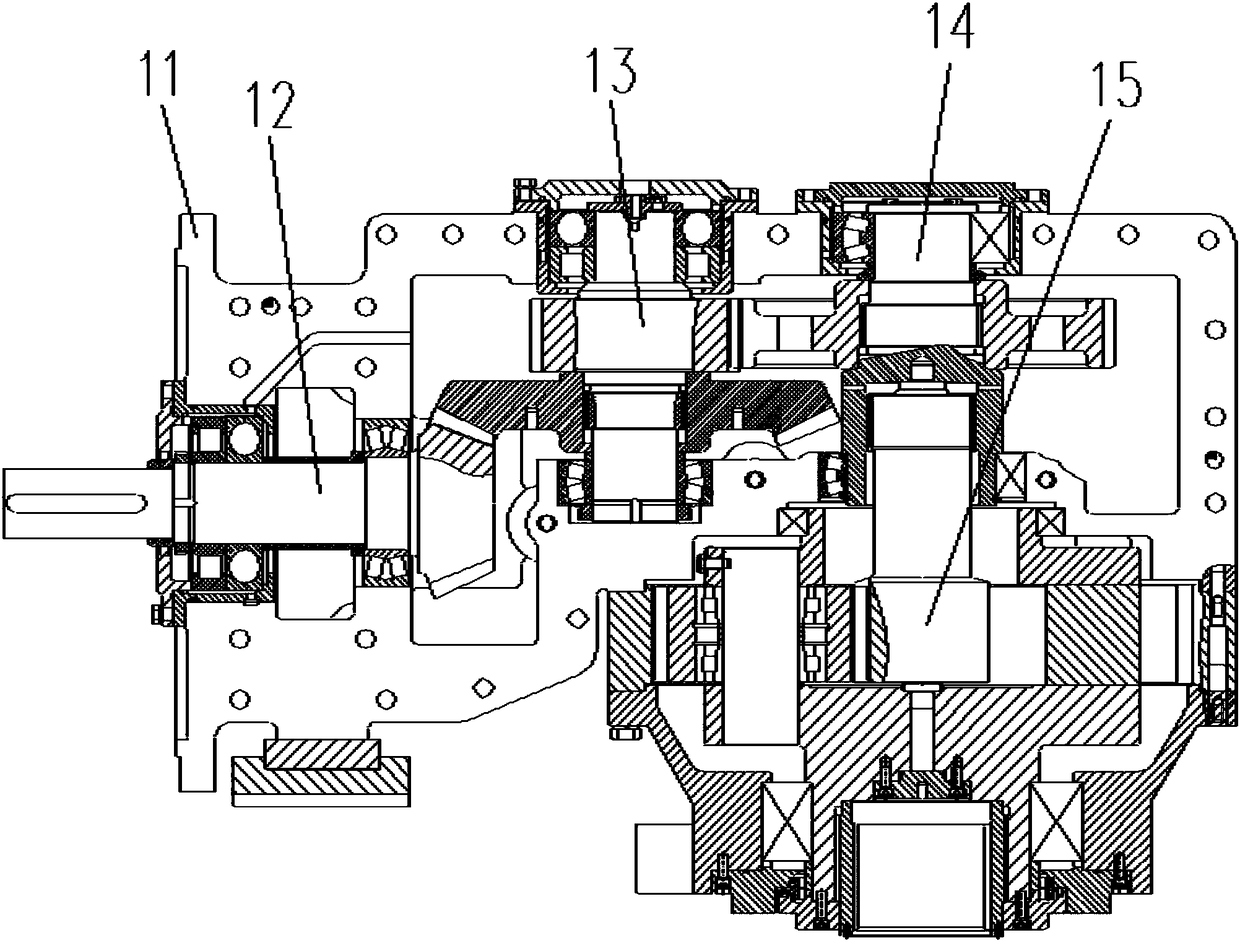

Embodiment 1

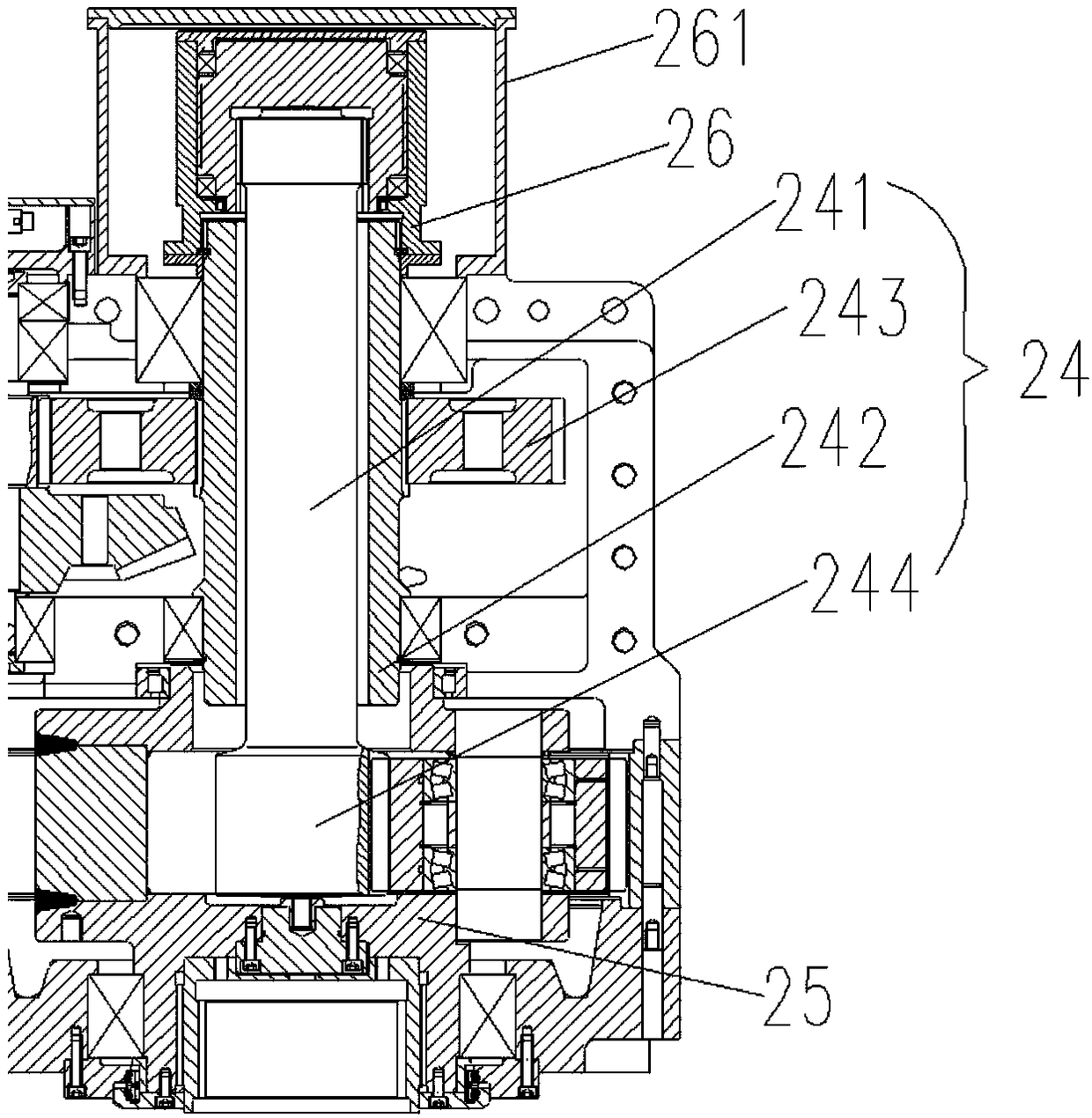

[0034] When the torque-limiting reducer of Embodiment 1 is in normal operation, the motor at the power input end drives the drive wheel on the passive side of the first-axis assembly 2 to rotate, and the drive wheel on the passive side of the first-axis assembly 22 drives the drive wheel on the driving side of the second-axis assembly 23 to rotate. , the driven side transmission wheel of the two-axis assembly 23 drives the driving side transmission wheel of the three-axis assembly 24 to rotate, and the shaft sleeve 242 connected to the active side transmission wheel of the three-axis assembly 24 rotates synchronously, and drives the shaft 241 and the sun gear 244 to rotate , and then the sun gear 244 drives the planetary gears in the output assembly to rotate. When the output end of the reducer is stuck and stalled, the output end stops rotating, while the motor at the input end runs normally. When the torque difference between the input and output exceeds the maximum torque se...

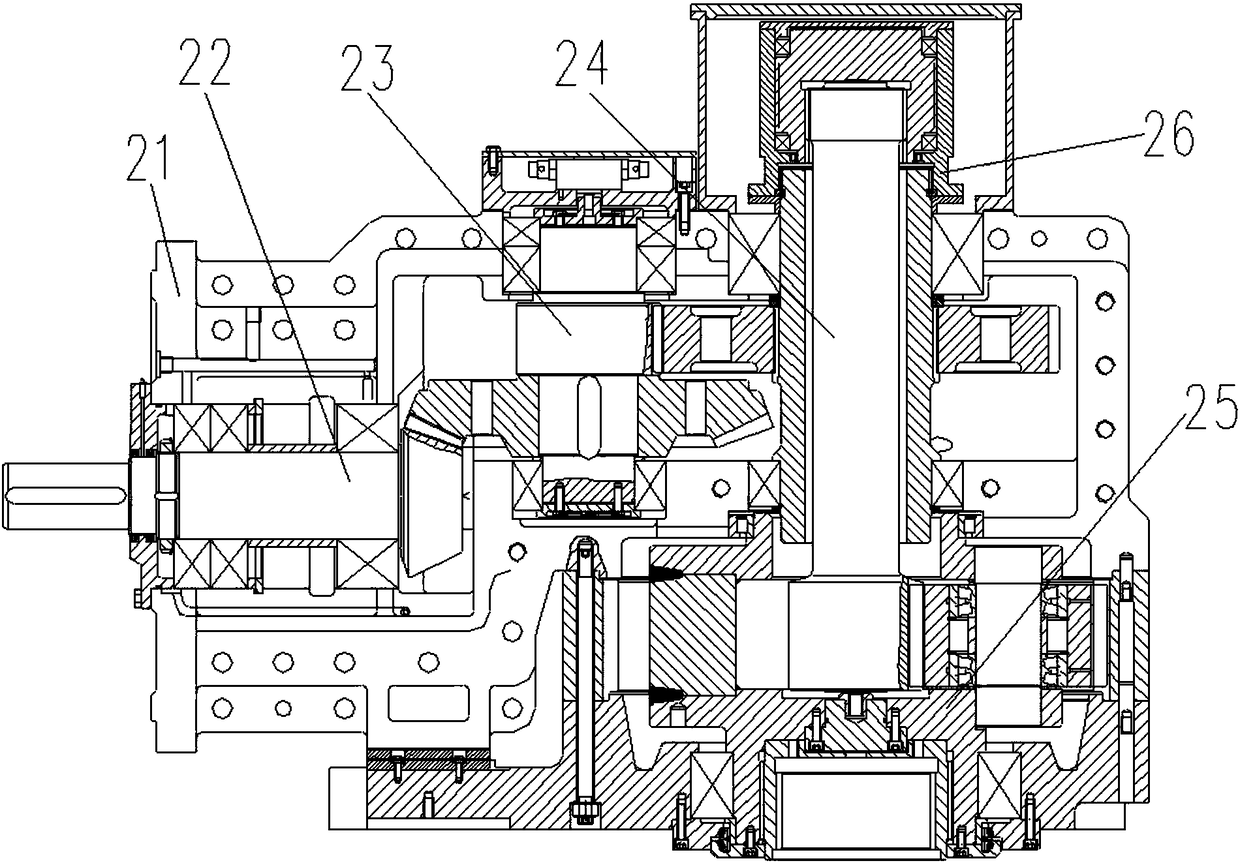

Embodiment 2

[0035] The main difference between the structure of the torque-limiting reducer provided in Embodiment 2 and the structure of the torque-limiting reducer in Embodiment 1 is that the shaft assembly connected to the torque-limiting device 26 at the shaft end is the two-axis assembly 23 in the planetary reducer. In the torque-limiting reducer of Embodiment 2, the two-shaft assembly 23 includes a shaft and a shaft sleeve. The outer periphery of the shaft sleeve is provided with a driving side drive wheel, and the part of the shaft exposed from the end of the shaft sleeve away from the torque limiting device 26 is provided with a passive gear. Side drive wheels. The torque-limiting reducer of Embodiment 2 also includes a shaft assembly 22 and a three-shaft assembly 24, the driving side drive wheel of the two-shaft assembly 23 is connected to the power input end through the first shaft assembly 22, and the passive side transmission wheel of the two-shaft assembly 23 It is connected ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap