Safety lamp holder

A safety lamp cap and lamp cap technology, which is applied to lighting devices, lighting device parts, lighting auxiliary devices, etc., can solve the problem of increasing the structural complexity and design difficulty of the lamp cap, increasing the production, use and maintenance costs of the lamp cap, and limiting the lighting angle of the lamp. It can achieve the effect of rich practical functions, avoiding the complex structure of lamp caps, strong practical value and market promotion value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

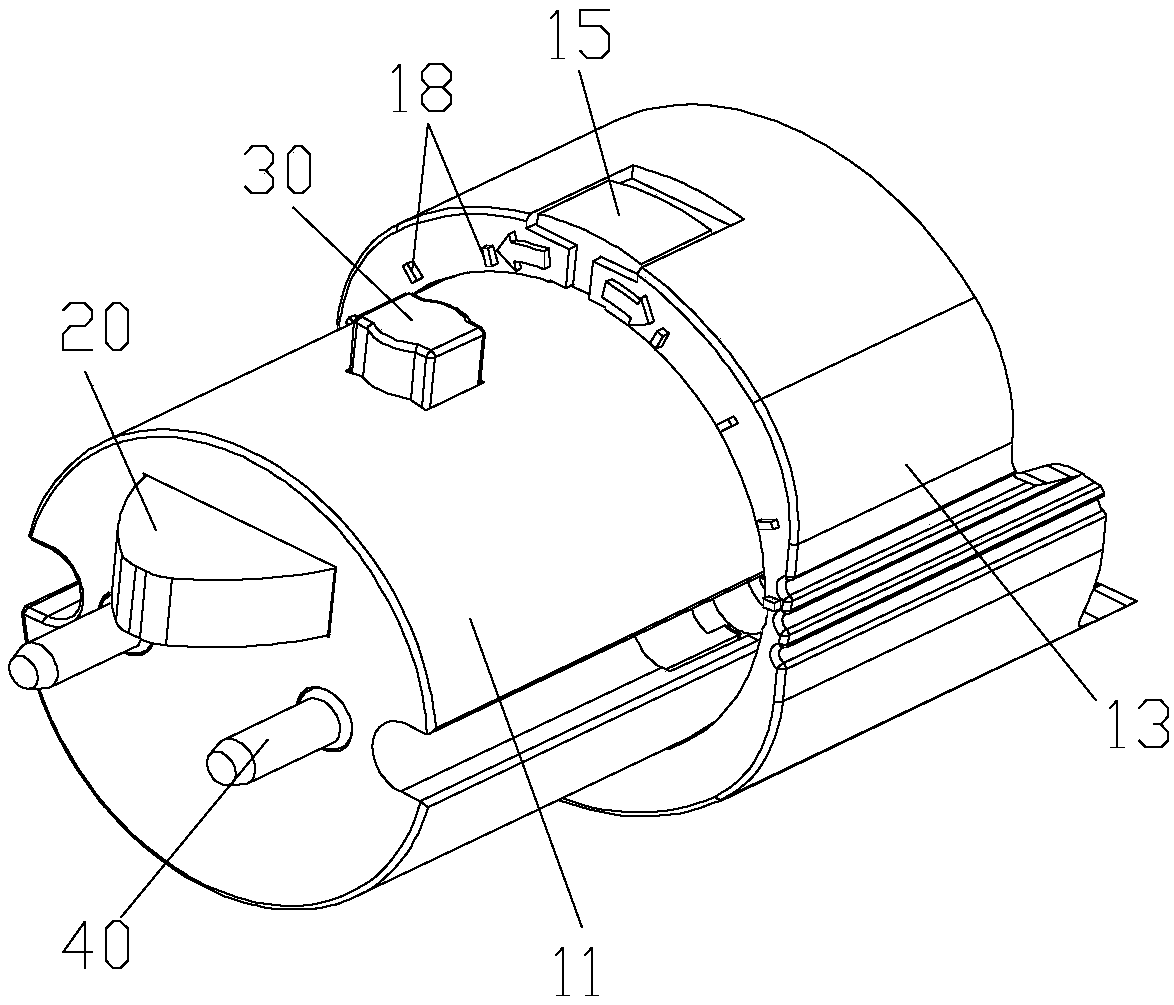

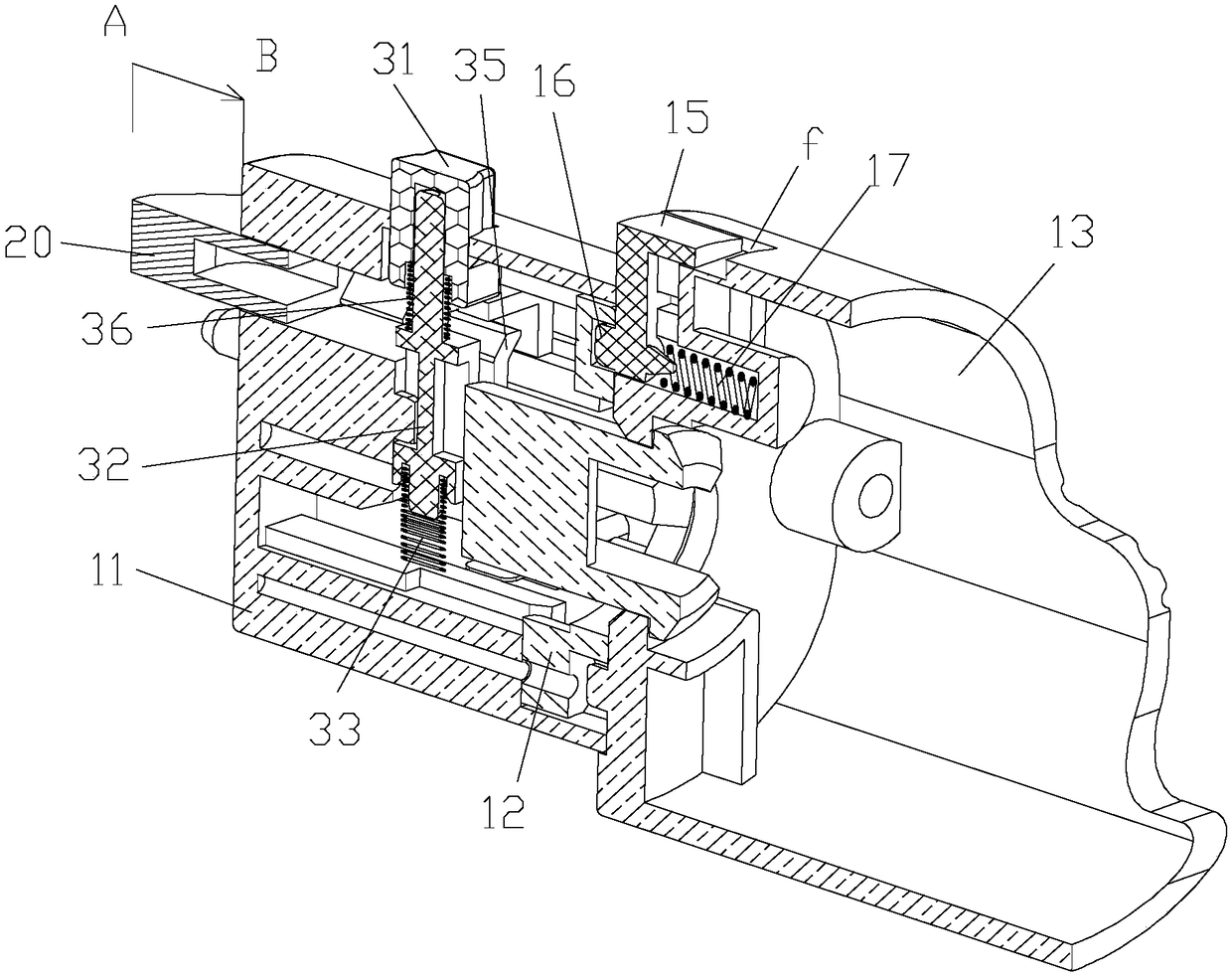

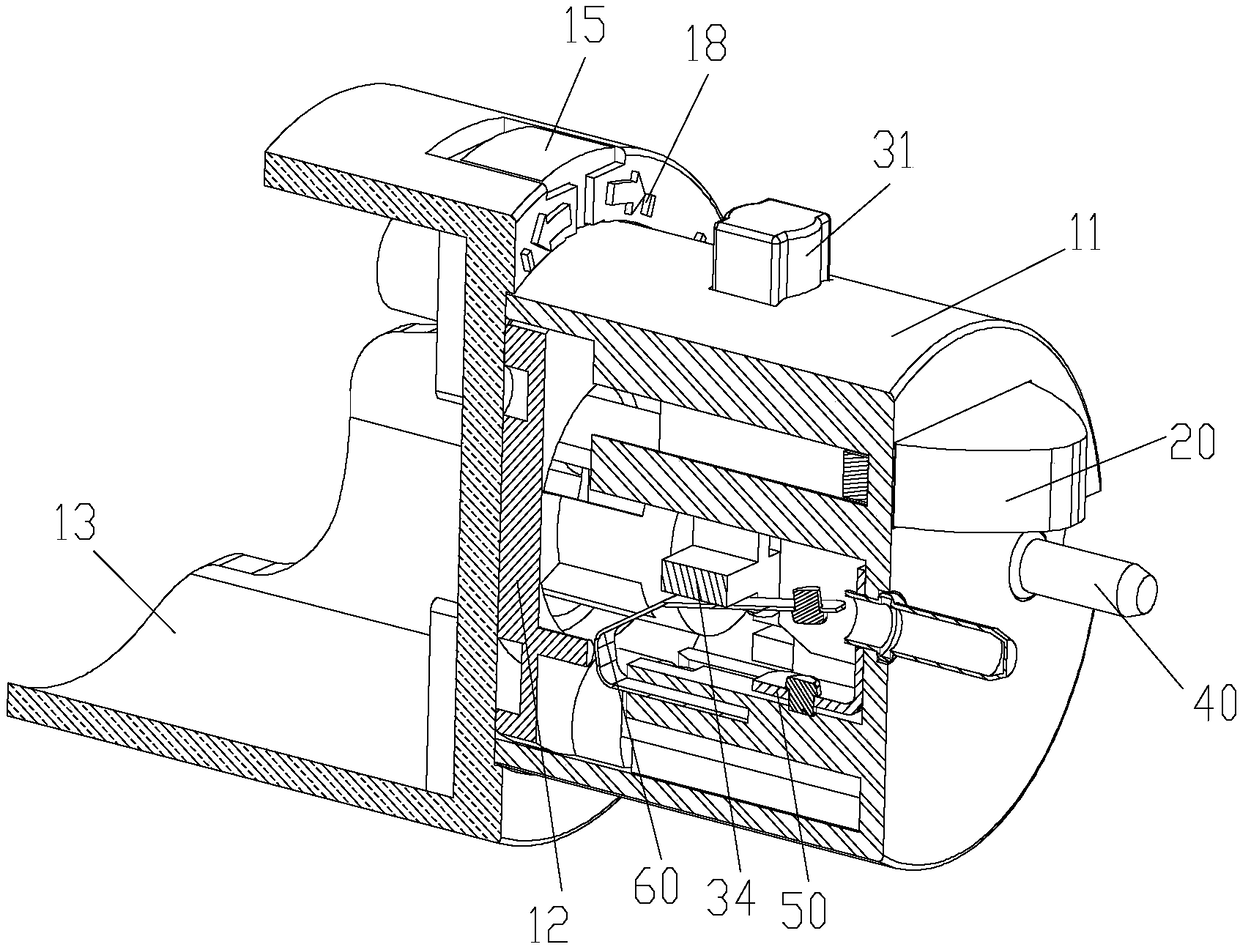

[0042] Such as Figure 1 to Figure 9 As shown, the present embodiment provides a safety lamp cap, which includes:

[0043] A lamp head body 10, which is a tubular structure with an inner cavity structure;

[0044] A safety button 20, the main body of which is inserted into the lamp body 10 by the front end surface of the lamp body 10 and can be positioned between the locking position A and the unlocking position B along the axial direction of the lamp body 10 when the pressure is applied or the pressure is released. Make reciprocating motions; at the same time, a stop lock a is provided on the main body part of the safety button 20 (that is, the part inside the lamp head body 10);

[0045] A switch button 30, the main part of which is inserted int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com