Alloy preparation smelting furnace remote filling device with protection function

A protection function, furnace technology, applied in furnaces, crucible furnaces, furnace types, etc., to achieve the effect of reducing personal danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

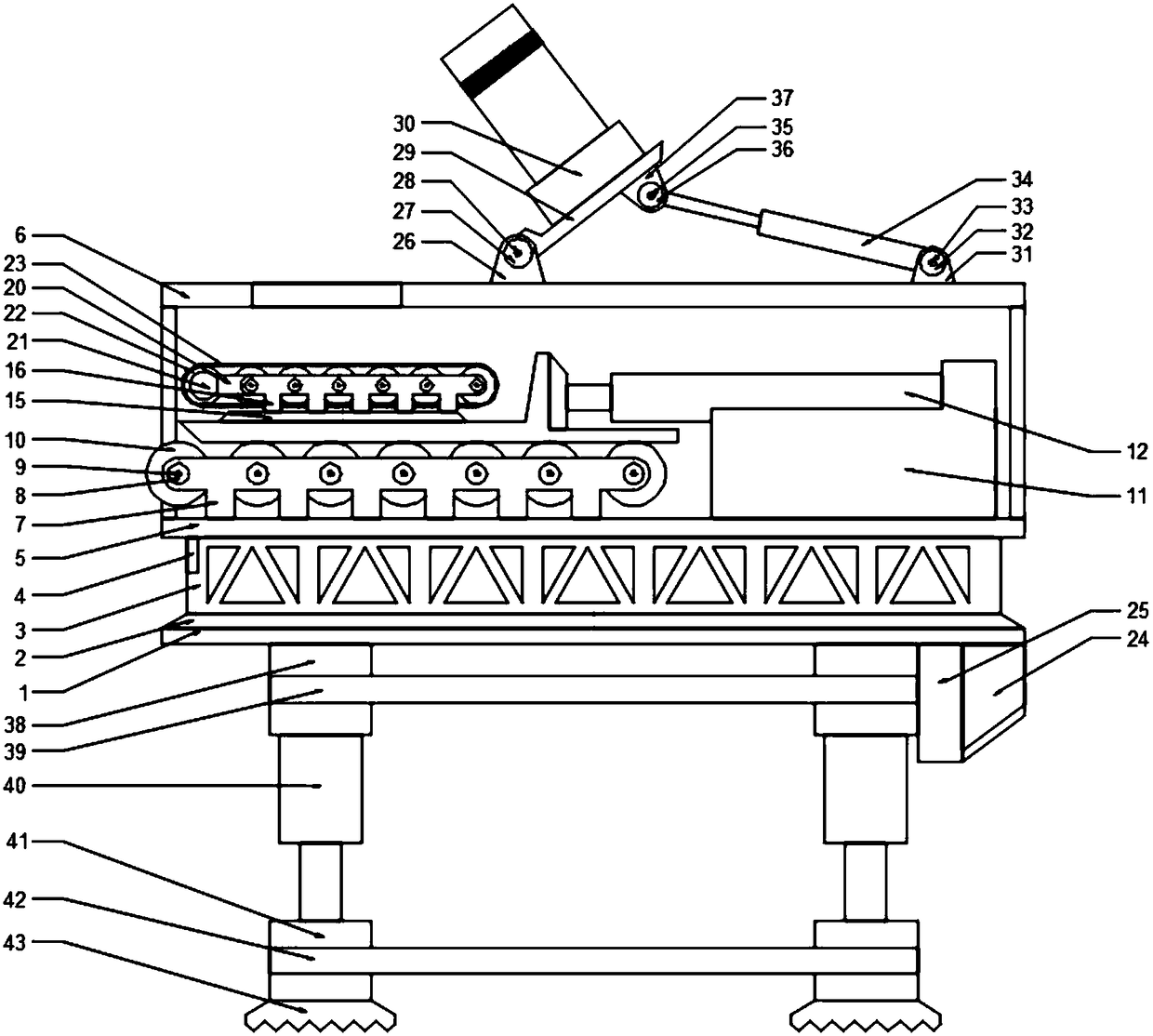

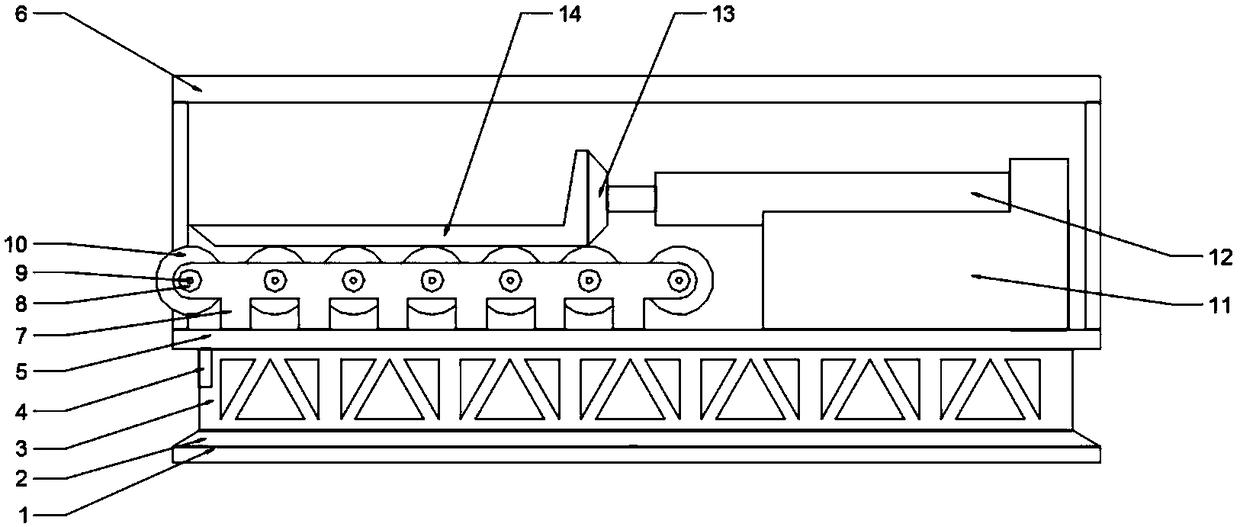

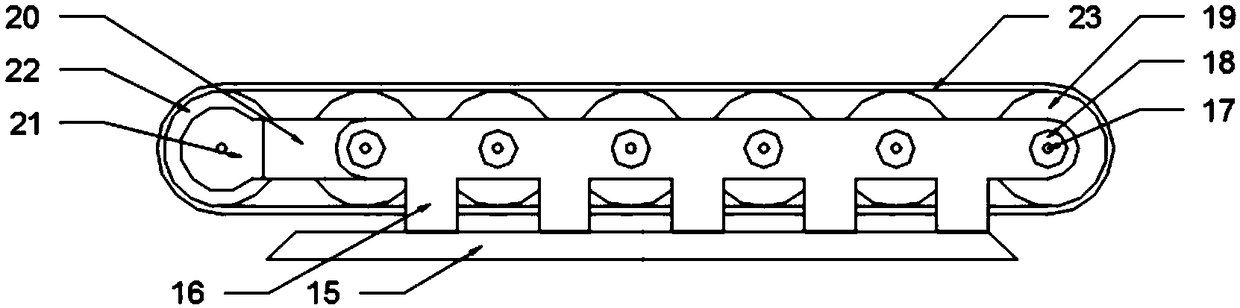

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 As shown, a remote filling device for an alloy preparation furnace with a protective function includes a base 1, the base 1 is located above the furnace, and a transmission mechanism is provided above the base 1, and the transmission mechanism is fixedly connected by a base located above the base 1. Transmission support frame 2, heat insulation heat dissipation frame 3 installed on the transmission support frame 2, temperature sensor 4 installed on the heat insulation heat dissipation frame 3, transmission installation frame 5 installed above the heat insulation heat dissipation frame 3, installed on the transmission installation The unloading support platform 6 above the frame 5, the support transmission wheel frame 7 fixedly connected with the support transmission installation frame 5 inside the discharge support platform 6, several support transmission bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com