A fully automatic temperature measurement and sampling device outside the furnace and its method

A sampling device, fully automatic technology, applied in the field of metallurgy, can solve problems affecting production efficiency and casting slabs, operators' personal safety and health threats, to reduce personal risks, protect personal safety and health, and achieve high accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

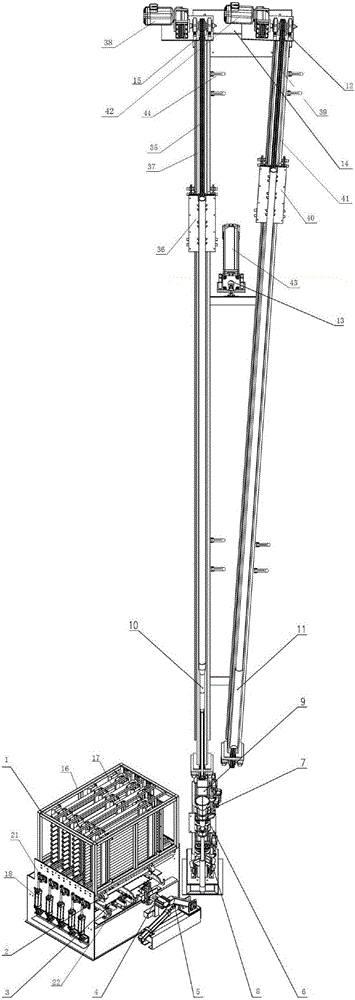

[0059] In order to solve the shortcomings of manual temperature measurement and sampling in the process of refining outside the furnace in steelmaking production, this scheme provides a method such as figure 1 The fully automatic temperature measurement and sampling device outside the furnace includes an automatic control module with PLC as the control core, and a gun magazine. The gun module, and the execution module above the gun module;

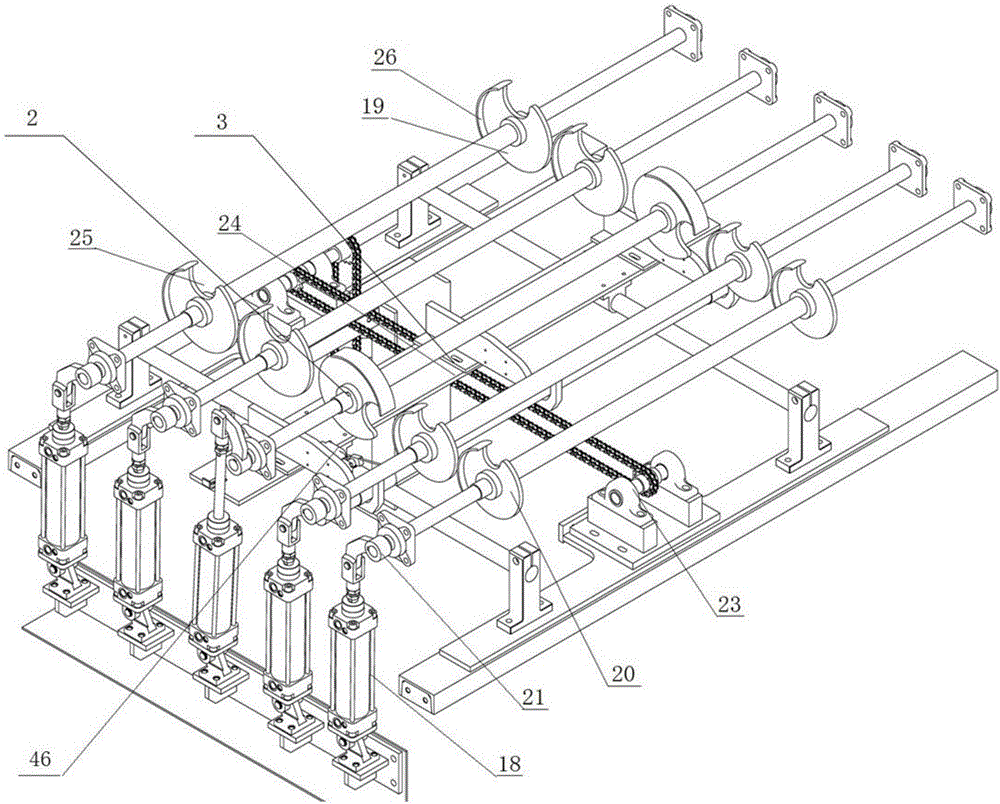

[0060] Such as image 3 As shown, the gun storehouse is composed of a gun storage rack 1, a gun-down mechanism 2 arranged under the gun rack 1, and a gun head conveying mechanism 3 arranged under the gun-down gun mechanism 2 below the gun rack;

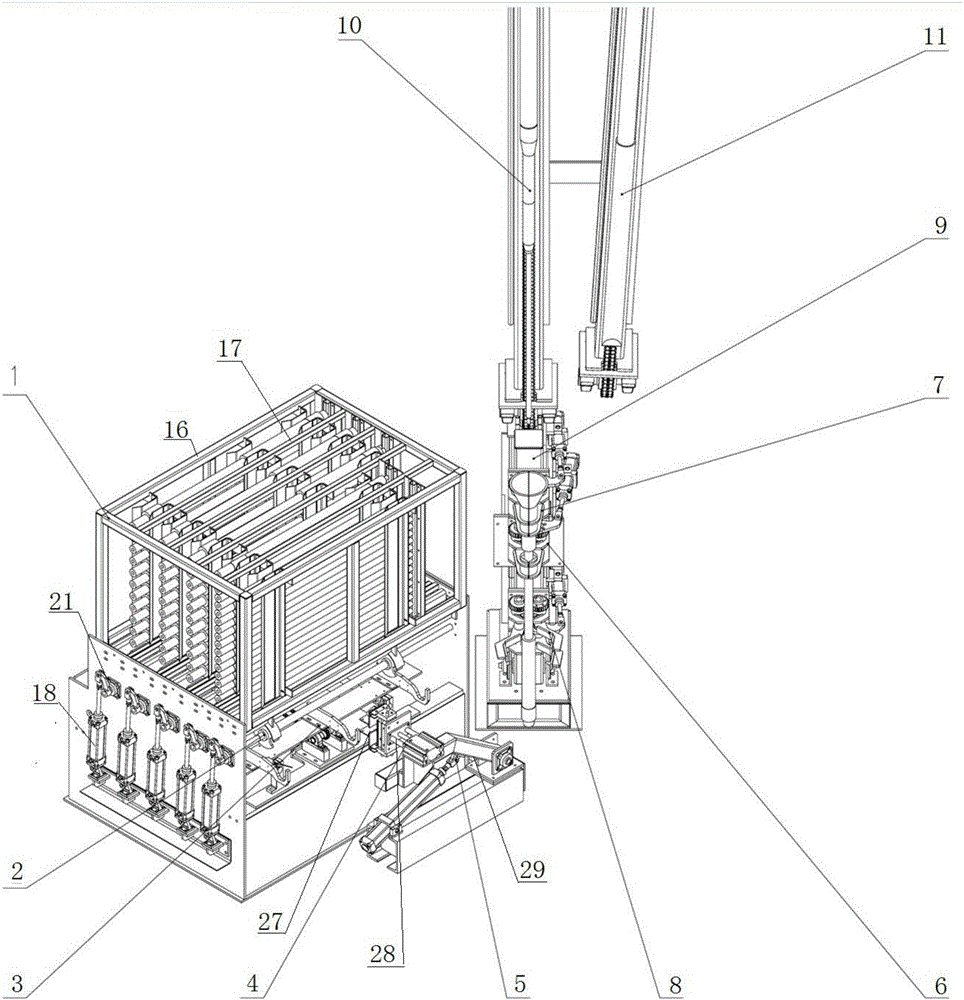

[0061] Such as figure 2 As shown, the gun-taking and gun-delivering module is composed of a gun clamping and releasing mechanism 4 coordinated with the gun head conveying mechanism 3 and a gun delivery mechanism 5 connected with the clamping and releasing mechanism 4;

[0062] Such as Figure...

Embodiment 2

[0084] A kind of automatic temperature measurement and sampling method outside the furnace, such as Figure 8 , Figure 9 The full-automatic temperature measurement and sampling method outside the furnace includes the following steps:

[0085] Step 1: The various parts of the fully automatic temperature measurement and sampling device outside the furnace: the gun storehouse, the gun taking and sending module, the gun insertion and drawing module, and the execution module are initialized to a ready state;

[0086] Step 2: Put the gun head of the corresponding specification into the gun rack 1 in the gun library;

[0087] Step 3: When the PLC receives the preparation command from the human-machine interface HMI, it controls the gun head conveying mechanism 3 in the gun magazine to move to the bottom of the gun rack 1 corresponding to the gun head;

[0088] Step 4: The cylinder in the gun-stopping gun mechanism 2 extends out, and the gun-blocking ring unscrews the gun head to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com