Visual device with oblique cambered surface and variable channel

A flow channel and variable technology, applied in measuring devices, components using electrical devices, thermometers, etc., can solve the problems of inability to adjust the flow field structure and gap size, and achieve accurate and reliable visual measurement, shorten the cycle, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

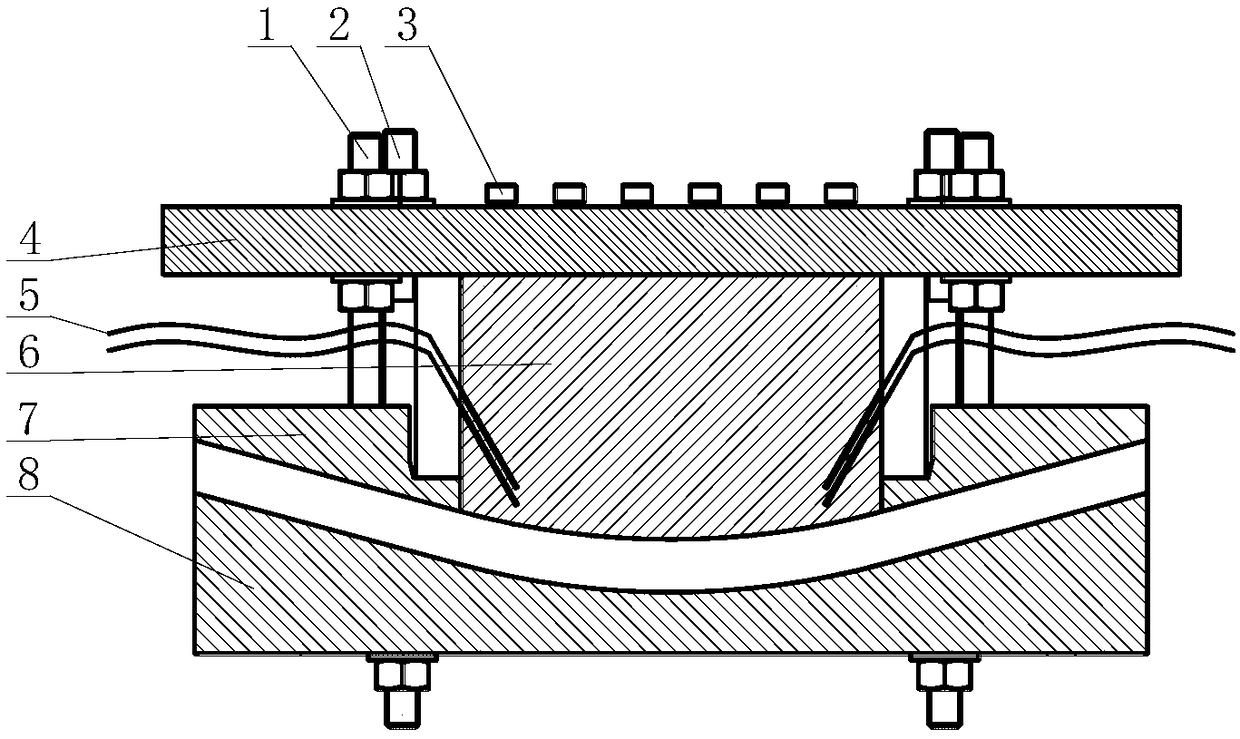

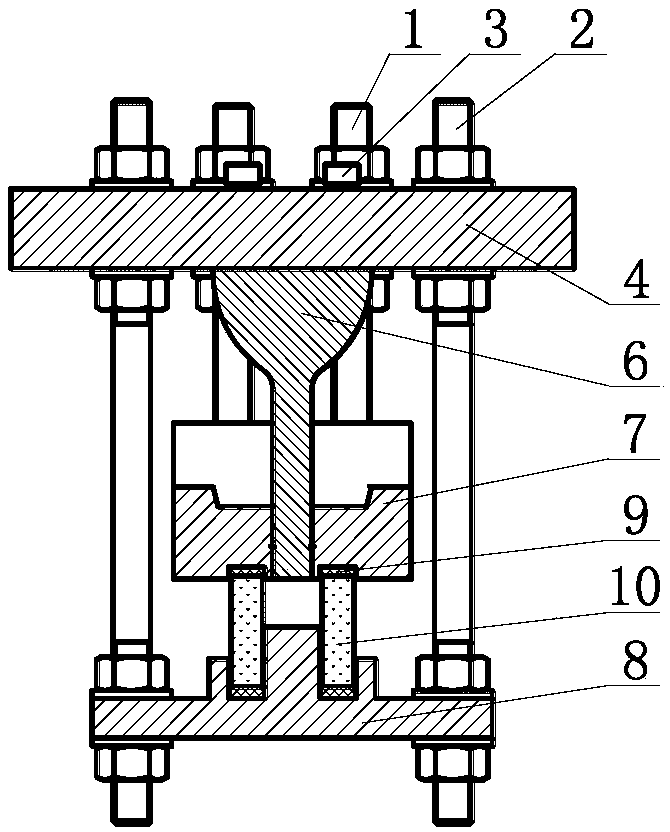

[0031] See attached figure 1 , attached figure 2 , first install the positioning plate 4 on the external rotating bracket; then screw a set of screws 3 downward from the top of the positioning plate 4 to connect the heating element 6; then screw the studs of a set of bolt combination I1 into the top shape plate 7 Corresponding to the assembly hole, insert the studs of the bolt combination I1 into the positioning plate 4 from the bottom of the positioning plate 4 after assembly, tighten the nuts and adjust the relative position of the upper shape plate 7; then fix the bolt combination II2 on the positioning plate 4 , connect the lower shape plate 8 with the bolt combination II2, and reserve enough space; then put the sealing gasket 9 into the sealing groove of the lower shape plate 8, and put the glass 10 in the sealing groove with the sealing gasket 9 , place another group of gaskets 9 on the other end of the glass 10; then gradually adjust the assembly position of the nut a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com