Rolling vibration experiment platform

An experimental platform, magnetic powder brake technology, applied in vibration testing, measuring devices, testing of machine/structural components, etc., can solve the problems of inability to study the rolling vibration mechanism and the effect and effect of rolling stock forming quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

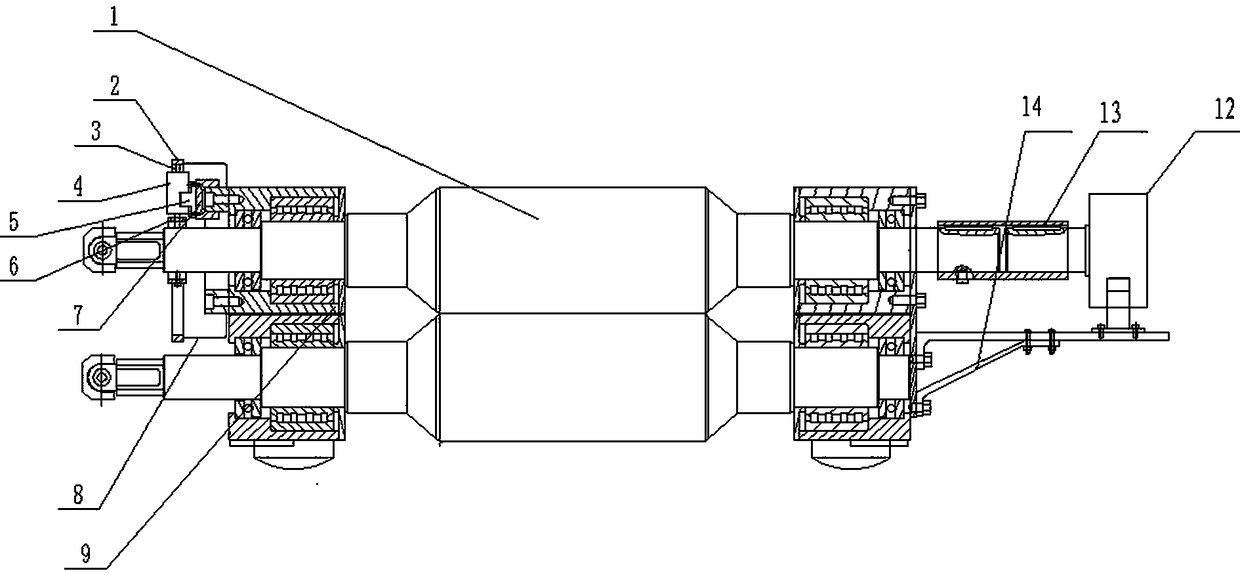

[0034] The rolling vibration experiment platform adopted in this embodiment, such as figure 1 shown. The rolling vibration experiment platform includes an upper work roll 1, and the upper work roll 1 includes a transmission side shaft end located at the left end and an operation side shaft end located at the right end, and a control shaft end of the upper work roll is arranged on the transmission side shaft end. The radial vibration exciter 4 is connected to the shaft end of the operation side with a magnetic powder brake 12 that controls the torsional vibration of the upper work roll in the circumferential direction, and the magnetic powder brake 12 is coaxially arranged with the upper work roll 1 . When working, the exciter 4 is cleverly used to realize the radial vibration of the upper work roll, and the magnetic powder brake 12 is used to realize the torsional vibration of the upper work roll along the circumferential direction. The output shaft of the magnetic powder bra...

Embodiment 2

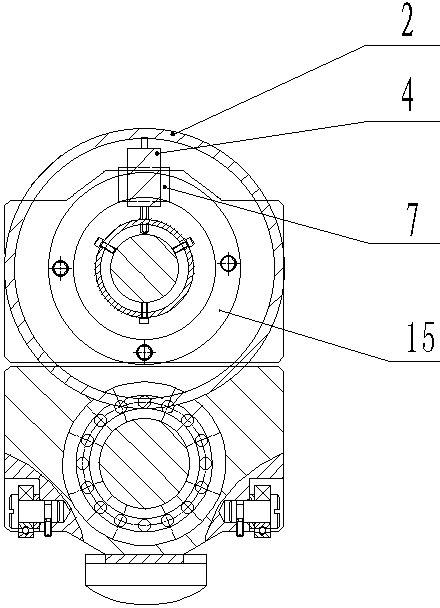

[0042] In this example, if Image 6 As shown, on the basis of Embodiment 1, two guide rail sliders 7 are provided on the annular guide rail 15 along the circumferential direction, and the guide rail sliders 7 are equipped with exciters 4, and the two exciters are in the The included angle of the central angle on the circumference is 90°, which is set as a horizontal vibrator 41 for controlling the horizontal vibration of the upper work roll 1 and a vertical vibrator 42 for controlling the vertical vibration of the upper work roll 1 . The exciter base 5 is fixed on the corresponding guide rail slider 7, and a clamp 6 is fixed at the shaft end of the transmission side, and a reserved hole is set on the clamp 6, and the ejector rod of the exciter 4 passes through The corresponding reserved holes are in contact with the peripheral surface of the transmission side shaft end to realize the synchronous rotation of the vibrator 4 and the upper work roll 1, and ensure that the ejector ...

Embodiment 3

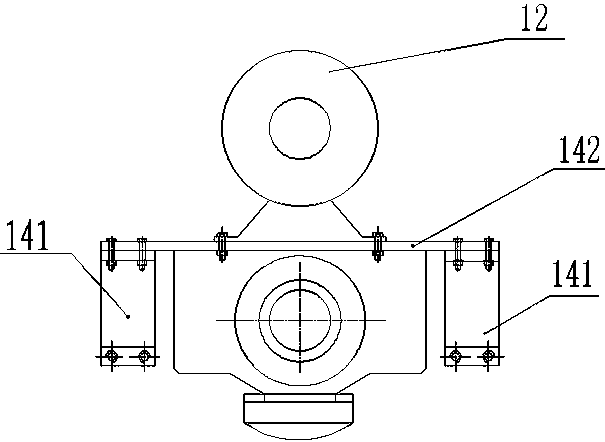

[0046] In this example, if Figure 7 As shown, on the basis of Example 2, the operating side shaft end and the magnetic powder brake 12 are connected through the coaxially arranged connecting shaft 10, and the experimental conditions are as close as possible to the actual production conditions without changing the original rolling mill structure. same. Preferably, the sleeve coupling includes a first sleeve coupling 13 and a second sleeve coupling 11, and the left end of the connecting shaft 10 is connected to the operating side shaft through the first sleeve coupling 13. The right end of the connecting shaft 10 is coaxially connected with the magnetic powder brake 12 through the second sleeve coupling 11, which improves the fixed connection effect between the connecting shaft 10 and the operating side shaft end and the magnetic powder brake 12. At the same time, as far as possible It is possible to simulate the actual working state, and provide effective experimental data fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com