Rotating workpiece noise assessment device

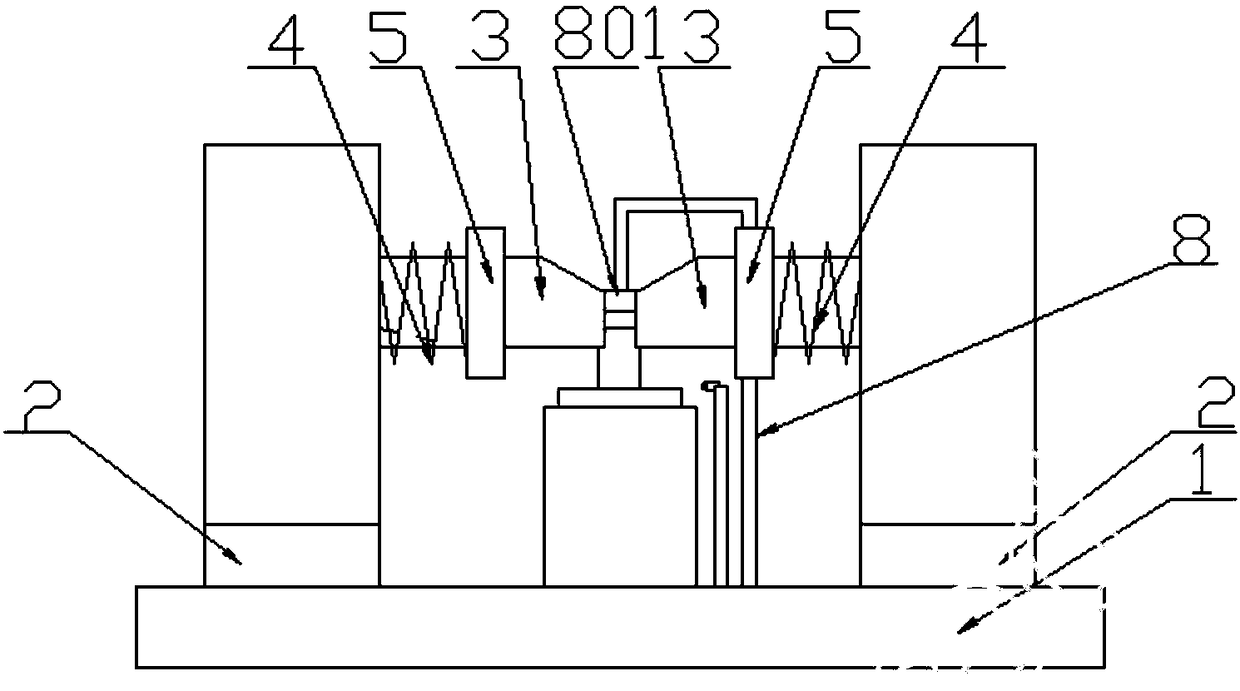

A rotating workpiece noise technology, applied in the field of rotating workpiece noise evaluator, can solve the problems of complex and cumbersome structure, no appearance, heavy equipment, etc., and achieve the effect of small size, simple assembly and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

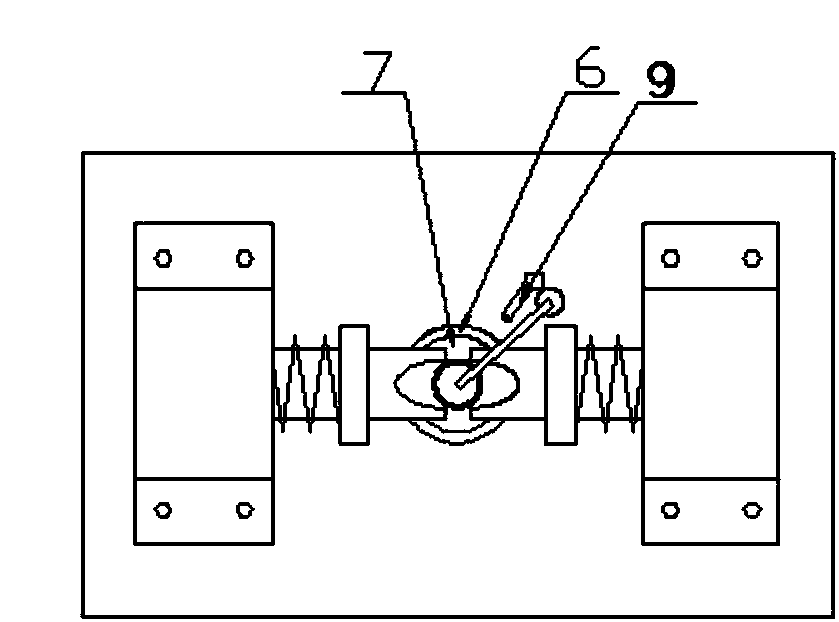

[0012] When carrying out the quality inspection of the bearing running-in, the bearing push rods 3 on both sides are respectively stretched outward and rotated 90° to fit and abut against the shallow groove 202, and then one end of the inner ring of the bearing is placed on the output shaft 701 of the running-in motor On the shaft shoulder 702 and abut against the shaft shoulder 702, the torque sensor nut 901 is screwed into the running-in motor output shaft 701, and abuts against the other end of the inner ring of the bearing, and continues to stretch the bearing push rods 3 on both sides outward, And make the ends of the two bearing push rods 3 leave the shallow groove; rotate 90°, so that the bearing push rods 3 on both sides can slide into the through hole 201 and contact the outer ring of the bearing to complete the clamping of the bearing running-in device and start The motor and the bearing are run-in, and the axial torque is changed by changing the screw-in length of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com