Column pressing machine used for quality analysis

A form of decentralized technology, applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve the problems of reducing product quality and processing difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It is an object of the present invention to provide a method by which the quality of a polymer-bound rubber additive can be reliably tested, and also equipment for carrying out the method.

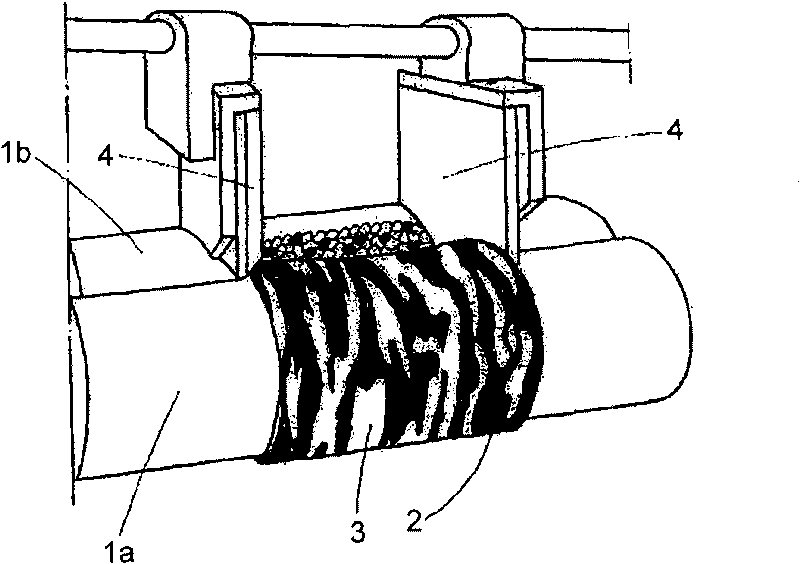

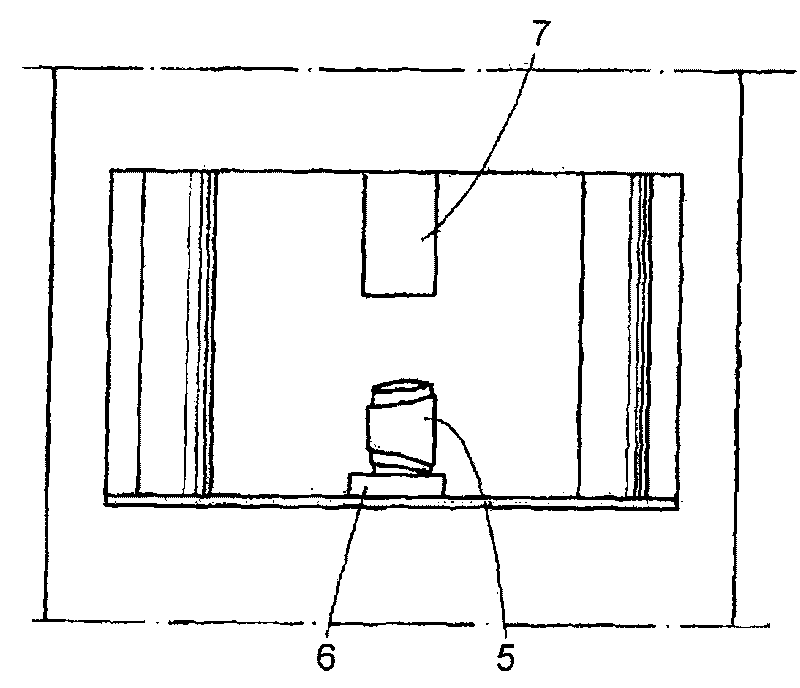

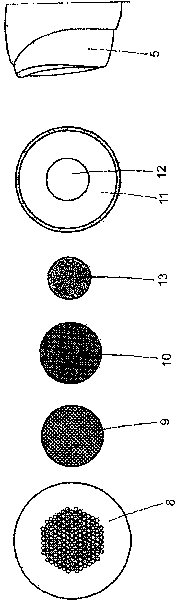

[0025] For this purpose, a test mixture was produced comprising the polymer-bound rubber additive to be tested and a test masterbatch. The test masterbatch preferably includes one or more rubbers, carbon black, light colored fillers, plasticizer oils, crosslinking activators and / or processing aids. The test mixtures were produced using in particular polymer-bound rubber additives (eg 100 g) and black EPDM masterbatches (eg 300 g). Black EPDM masterbatches include not only the polymer EPDM (ie ethylene-propylene-diene rubber), but also further additives, and precisely and especially large amounts of carbon black, and also oils as plasticizers. The purpose of using a test masterbatch is to provide the best possible simulation of a material actually used and thus allow reliable testin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com