Testing method capable of realizing whole-process tracing of shear strength test of structural plane

A test method and shear strength technology, applied in the field of geotechnical engineering, can solve the problem of inability to obtain the three-dimensional shape gradient law of the structural surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0026] Example: The whole process of the sight-tracking test method of the structural surface shear strength test of the present embodiment includes the following steps:

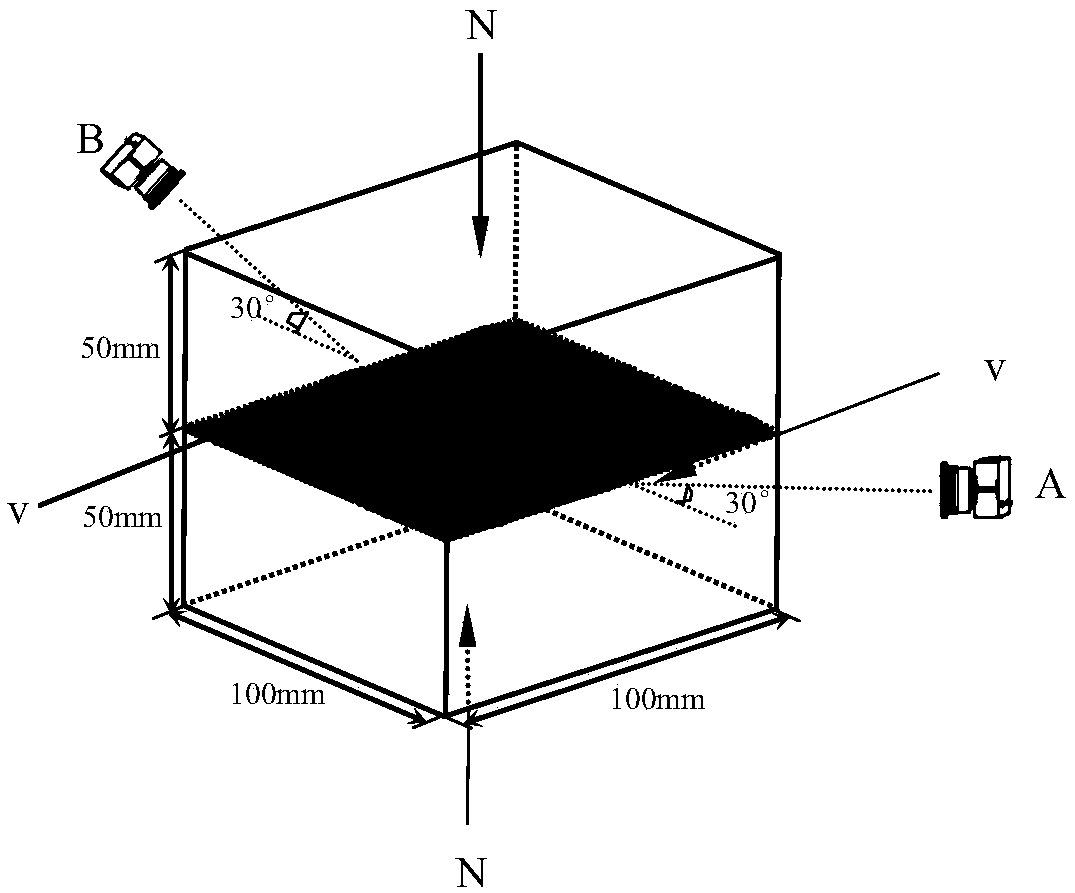

[0027] (1) Select an engineering rock mass structure surface with a side length of 100mm*100mm, perform 3D scanning of the original rock structure surface to obtain a model, and then 3D print the 3D model with a transparent material to obtain a similar model structural surface sample. A CCD camera is placed in the front and rear, which is responsible for the change of the structure surface in the two regions and the shooting of the crack expansion around the structure surface during the test process, so as to obtain the three-dimensional surface shape change in the shear progressive process. Camera A is responsible for the first half area, B The rear half of the camera, such as figure 1 shown.

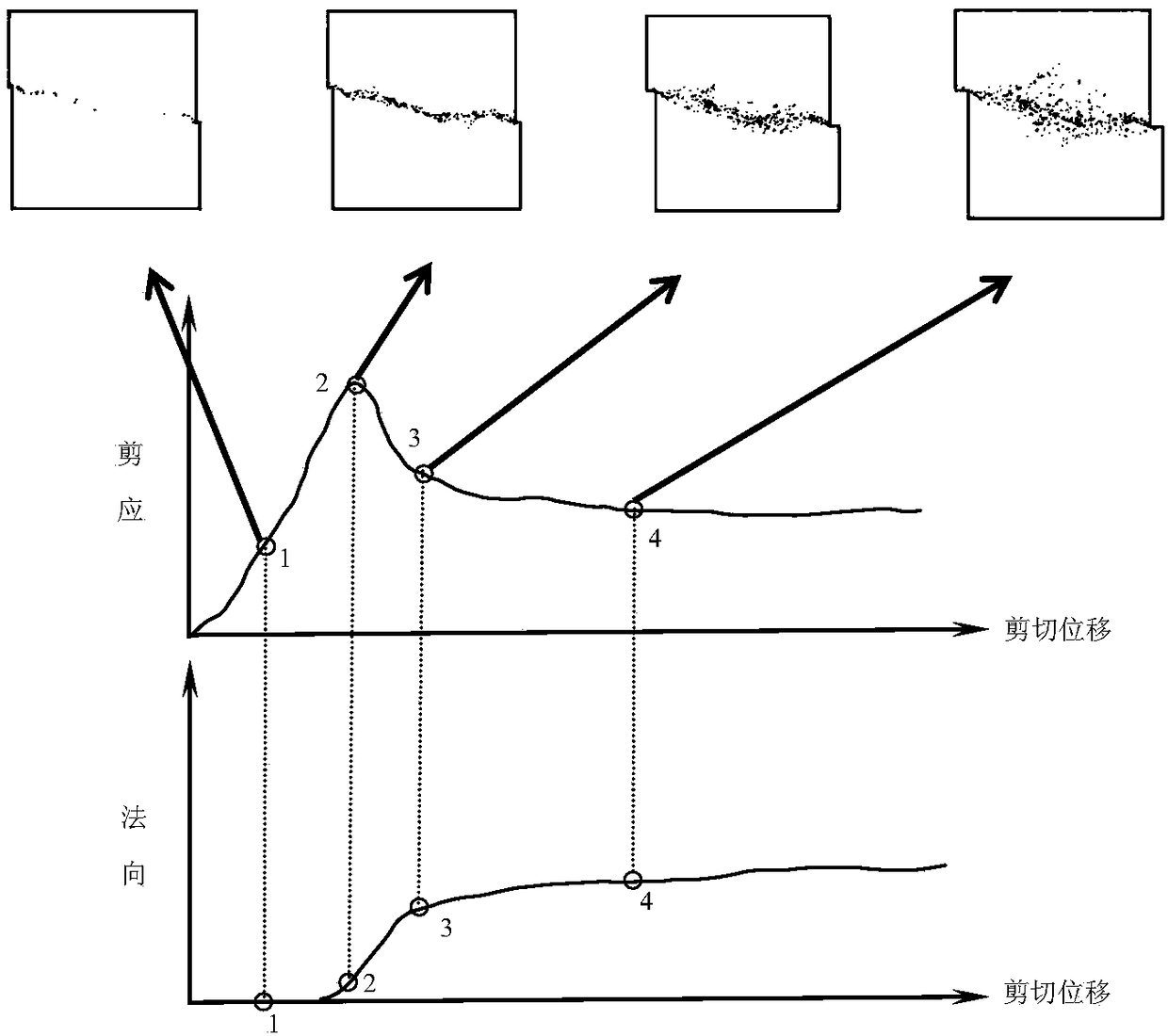

[0028] (2) Based on the whole-process visualization test method, the self-developed indoor rock structure plane d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com