Testing device for simulating natural gas hydrate decomposition induced seabed slope instability

A technology for hydrate decomposition and slope instability, applied in measuring devices, analytical materials, soil material testing, etc., can solve problems such as liquefaction, reduction of sediment strength and bearing capacity, softening of natural gas hydrate reservoirs, etc. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

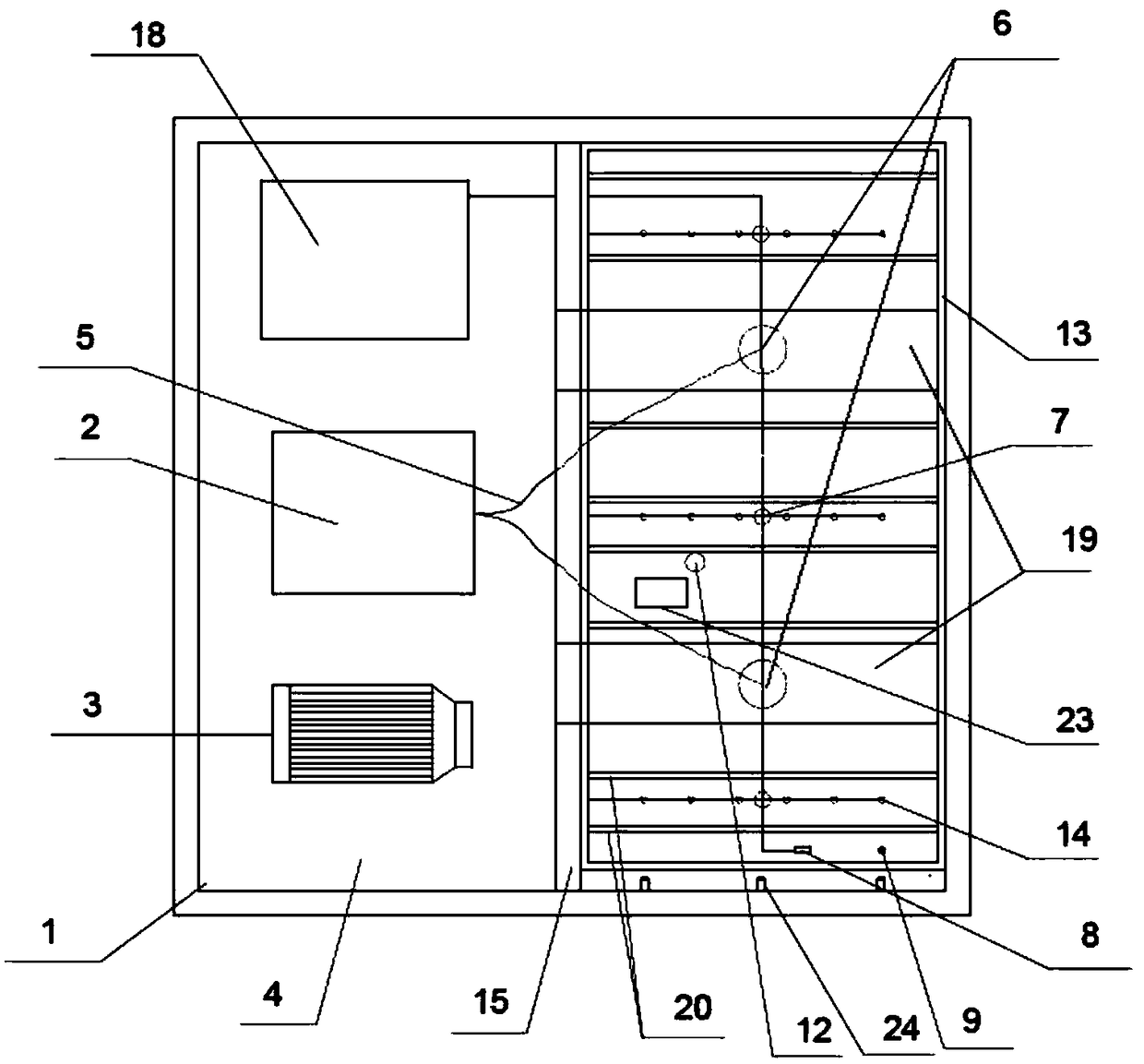

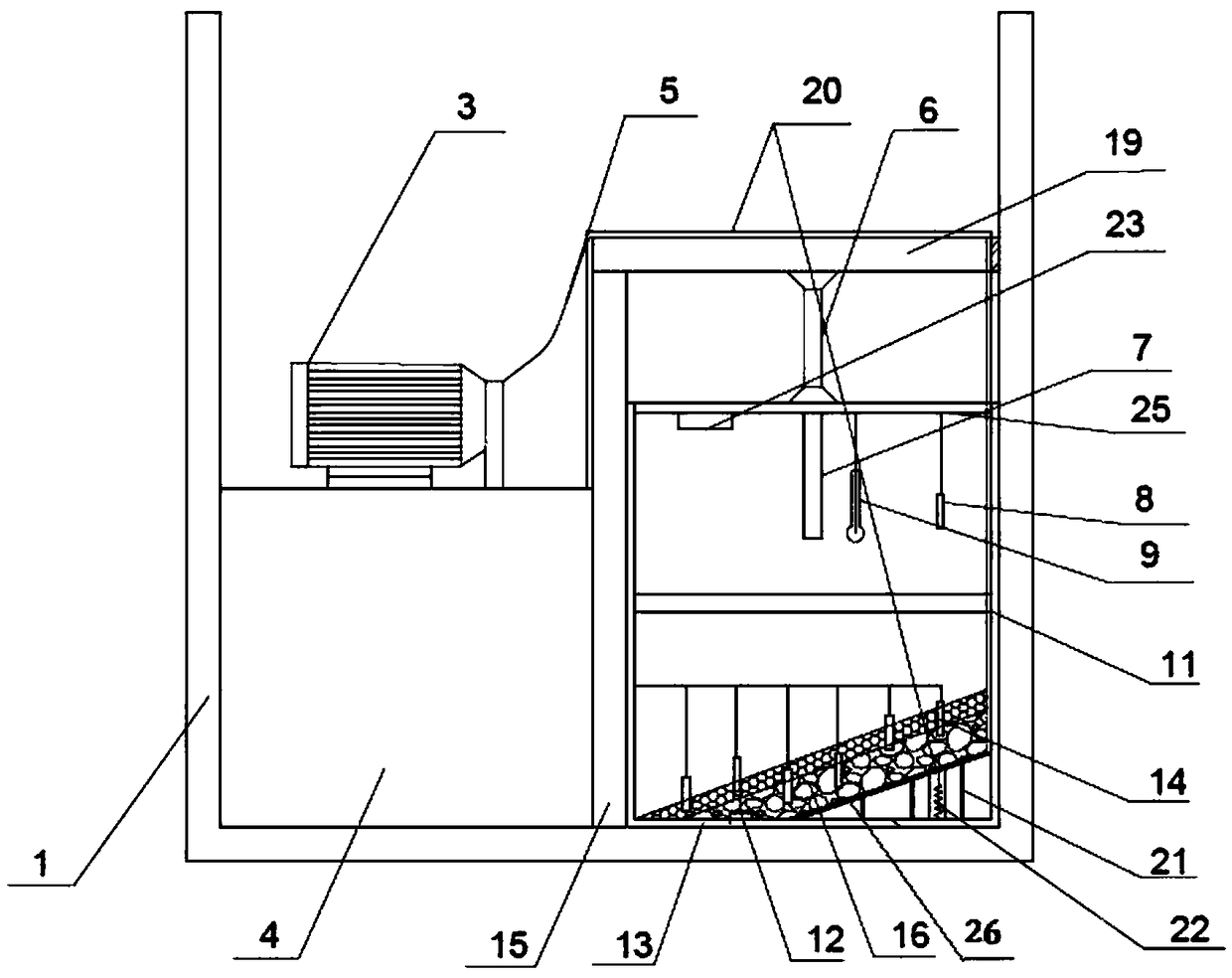

[0040] A test device for simulating the instability of seabed slopes induced by natural gas hydrate decomposition, refer to figure 1 For illustration, it includes a model box 1, a sealed box 13, a temperature control system, a pressure control system, a volume loss simulation system, a ventilation system, a data acquisition component and a model external monitoring system. The upper part of the model box 1 is open to facilitate the assembly and debugging of each component of the device. The front side of the model box 1 is a piece of transparent plexiglass, which is convenient for observing the internal soil. During the test, the model box 1 is installed in the hanging basket of the centrifuge. The partition 15 , sealing box 13 , temperature control system, hydraulic system, volume loss simulation system, ventilation system and data acquisition components are all placed in the model box 1 .

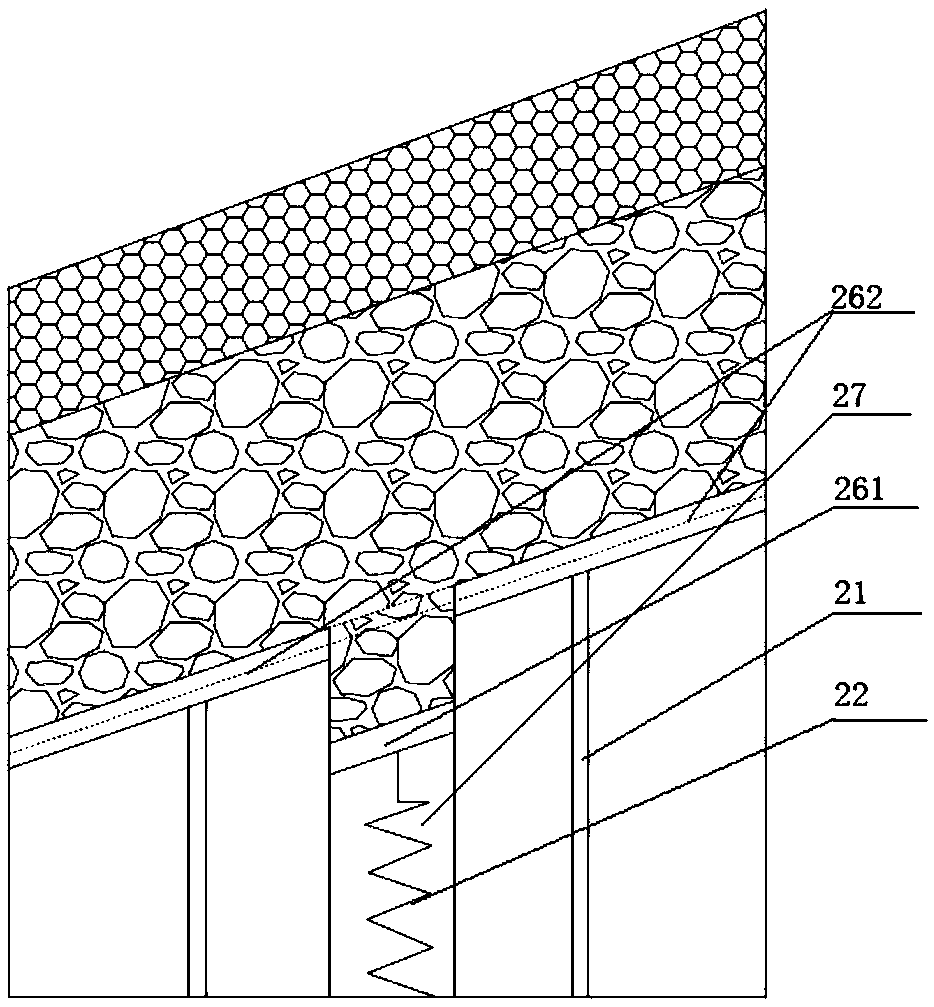

[0041] Such as figure 2As shown, the sealed box 13 adopts a high-strength glass sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com