Nanometer microcrystal mixed optical structure back projection high-definition image film and back projection screen

A nano-crystal, optical structure technology, applied in the field of optical projection, can solve the problems of unclear viewing, unclear imaging images, glare, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

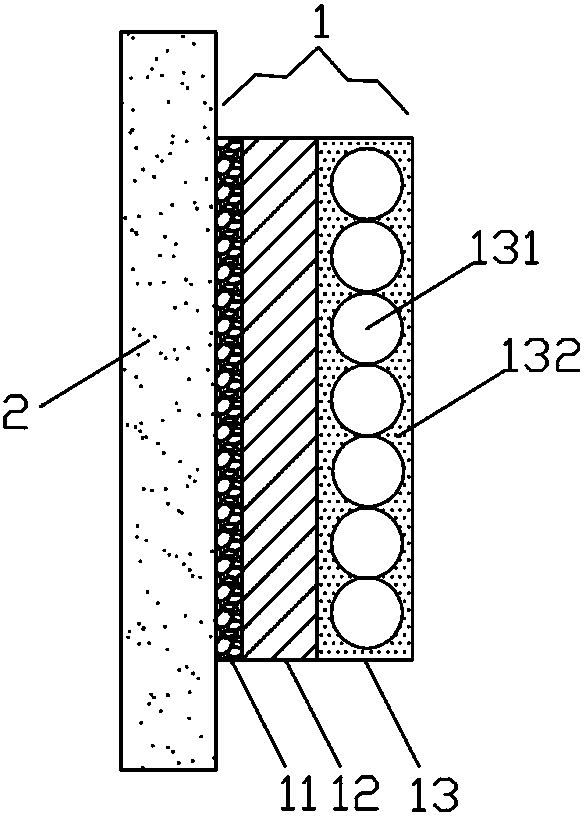

[0021] Such as figure 1 As shown, the first technical solution of this embodiment is specifically: a rear-projection high-definition image film 1 with a nano-microcrystal mixed optical structure, including a base layer 12, a nano-crystal and nano-bead hybrid imaging coating 13 and a rear projection film 1. Adhesive layer 11, the nano-crystal and nano-bead mixed imaging coating 13 is formed by mixing nano-crystal 132 and nano-bead 131 in proportion and uniformly coating on one side of the base layer 12, so The above-mentioned adhesive layer 11 is arranged on the other side of the base layer 12 for pasting on an external support. It should be noted that the external support here refers to glass, acrylic and other transparent and stickable carriers with suitable areas. (In Example 2, AG glass is selected as the external support, refer to Example 2 for details).

[0022] It should be pointed out that the nanometer microbeads 131 are optical microbeads, which act on the diffractio...

Embodiment 2

[0029] This embodiment is based on the rear projection screen of Embodiment 2, such as figure 1 As shown, it specifically includes the nano-microcrystalline mixed optical structure rear projection high-definition image film 1 and AG glass 2, and the back adhesive layer 11 of the nano-crystalline mixed optical structure rear projection high-definition image film 1 is pasted on the AG glass 2 On the bright side, it should be pointed out that the AG glass 2 is treated on the reflective surface of the original glass to a matte non-reflective surface. Compared with ordinary glass, AG glass has a lower reflectance, and the reflectance of light is increased by 8%. Reduced to less than 1%, so AG glass can form a clear and transparent visual effect, and achieve the ideal purpose of resisting reflection of ambient light and anti-glare protection.

[0030] In this embodiment, the thickness of the AG glass 2 is between 2-10 mm, and the optimum thickness in this embodiment is 4 mm.

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com