Combined cable tray

A cable tray and combined technology, applied in electrical components and other directions, can solve the problems of high cost, increase in width and height, increase in working time and cost, etc., and achieve the effect of reducing production cost and saving production materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments.

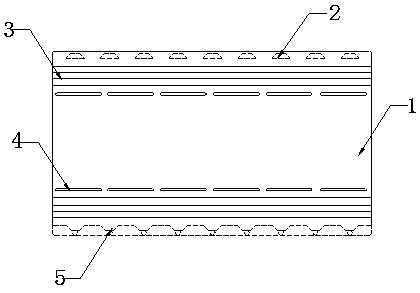

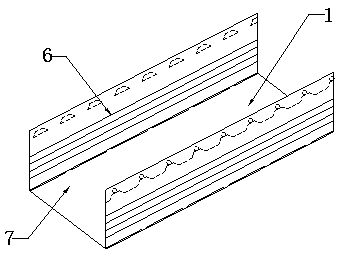

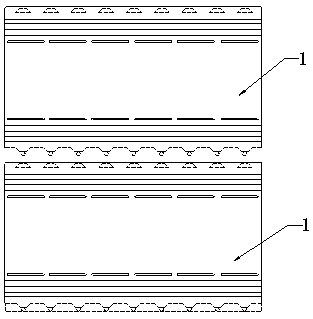

[0018] like Figure 1 to Figure 3 As shown, a combined cable tray includes a cable tray body 1, and the cable tray body 1 is provided with a bending waist hole 4, and a plurality of bending waist holes 4 form two parallel bending The bending line divides the cable tray body 1 into a side plate 6 and a bottom plate 7. The side plate 6 is divided into a left side plate and a right side plate. A connecting bump 5 matching with the knock-out hole 2 is provided on the top, and the edge of the connecting bump 5 is provided with a peelable folding line.

[0019] In order to further strengthen the bearing capacity of the cable tray, reinforcing ribs 3 are also provided on the left side plate and the right side plate.

[0020] The cable tray body 1 is made of aluminum alloy, the outer layer of the aluminum alloy is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com