Efficient method for manufacturing tooth preparation guide plates

A production method and high-efficiency technology, applied in dental prosthesis, dentistry, medical science, etc., can solve the problems of unfavorable popularization and application, low work efficiency, and difficult control of tooth preparation accuracy, so as to facilitate popularization and application and improve preparation accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0020] A method for making a high-efficiency tooth preparation guide plate of the present invention has the following steps:

[0021] 1) Scan the teeth and adjacent teeth that need to be prepared;

[0022] 2) Design the three-dimensional shape of the tooth preparation with three-dimensional reverse engineering software;

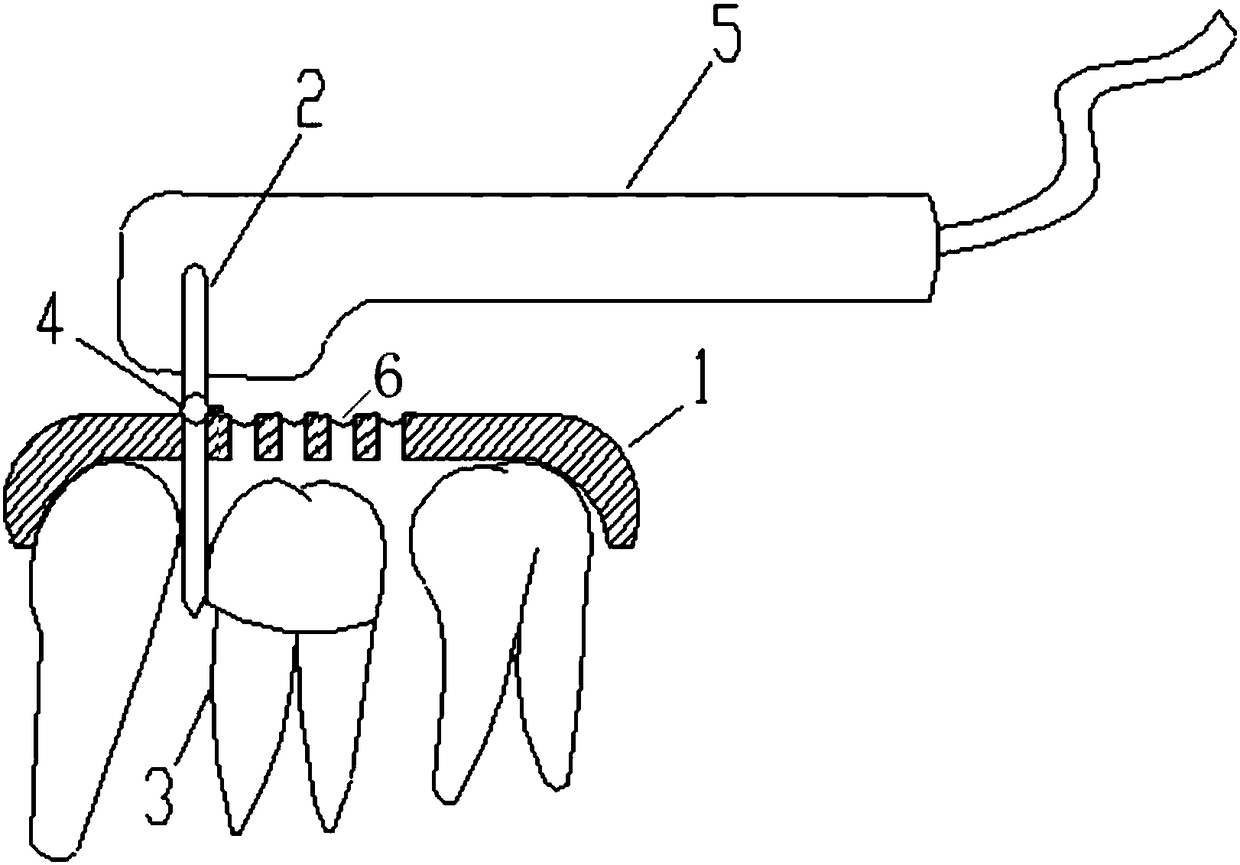

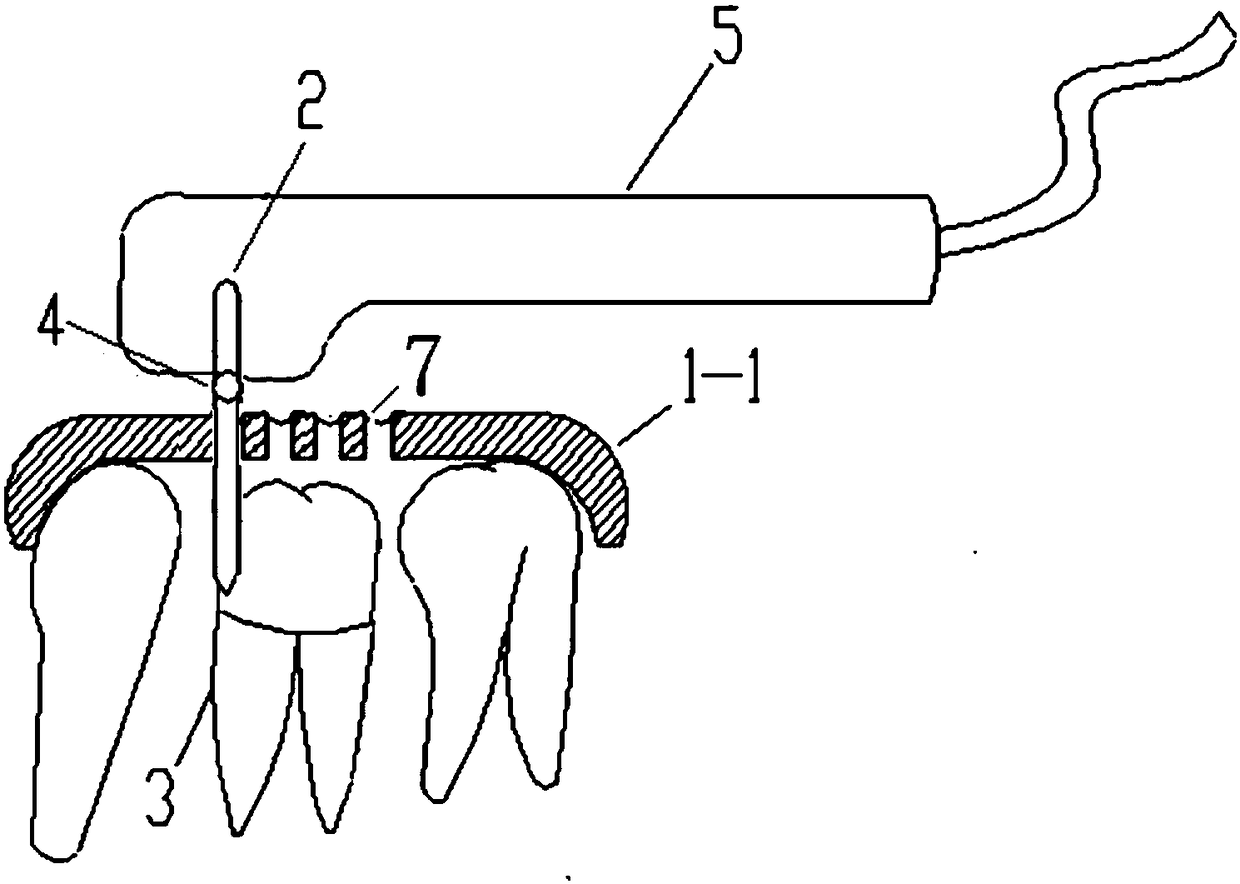

[0023] 3) Use 3D reverse engineering software to design 2 sets of guide plates for the preparation of the lip-buccal, lingual-palatal, and occlusal surfaces of teeth. There are guide grooves on the guide plates that can guide the movement path of dental burs. Each set of guide plates can guide 1 / 2 of the teeth. reserve amount;

[0024] 4) Thicken the data surface of the adjacent tooth crown to a thin wall of 1-4mm;

[0025] 5) Process the guide plate into a solid body with a three-dimensional printer or numerical c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com