Solid waste landfilling method

A solid waste and waste technology, applied in the direction of solid waste removal, landfill technology, etc., can solve the problems of squeezing and breaking the anti-seepage membrane, rupture of the anti-seepage membrane, and threats to the life and health of operators, so as to ensure the safety of landfills. , to ensure the effect of the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

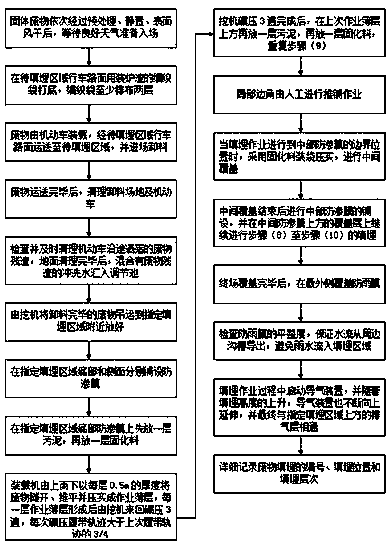

[0037] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, and only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0038] Such as figure 1 Shown, a kind of landfill method for solid waste, comprises the steps:

[0039] (1) After the solid waste is pretreated, put aside, and the surface is air-dried in sequence, wait for good weather to prepare to enter the site, so as to avoid inconvenient operation for staff in rainy and snowy weather, and at the same time prevent rain and snow from entering the waste during the landfill process and affecting the curing effect;

[0040] (2) Use slag-filled woven bags as the bottom layer on the driving road in the area to be landfilled. The woven bags are arranged in at least two layers, so the source is convenient and cheap, and the protec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com