Integrated multifunctional wrench

A multi-functional, integrated technology, applied in the direction of wrenches, manufacturing tools, wrenches, etc., can solve the problems of difficult to tighten or loosen screws, adjustable wrench takes up a lot of space, and poor versatility, so as to reduce the risk of attack and take into account the universality Performance, portability, and weight-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

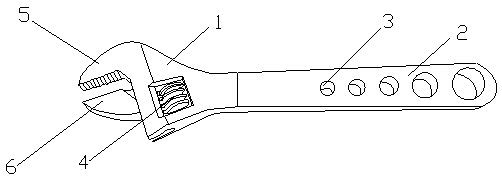

[0016] figure 1 A structural schematic diagram of an integrated multifunctional wrench provided for this embodiment, as shown in the figure, the integrated multifunctional wrench includes an opening part 1 and a handle part 2 connected to the opening part 1, and the handle part 2 A plum blossom garland 3 is arranged on it; the opening part 1 includes a movable plate lip 6 and a rigid lip 5 , and also includes an adjustable wrench worm wheel 4 .

[0017] Wherein, the number of the plum blossom garlands 3 is five; the movable lip 6 and the rigid lip 5 are respectively provided with anti-slip grooves.

[0018] When using an adjustable wrench to tighten the bolts and nuts, the operator holds the handle part 2 in the figure with his hand to perform operations. When turning a large nut, a larger torque is often used, and the hand should be held near the end of the handle; when turning a small nut, the torque used is not large, but the nut is too small and easy to slip, so the hand ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com