Method and device for inspecting the condition of vacuum suction units of gripping device

A vacuum suction and vacuum technology, which is applied in the field of status inspection and control of vacuum aspirators, can solve problems such as damage to the normality of aspirator functions, and achieve the effect of simple inspection and quick inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

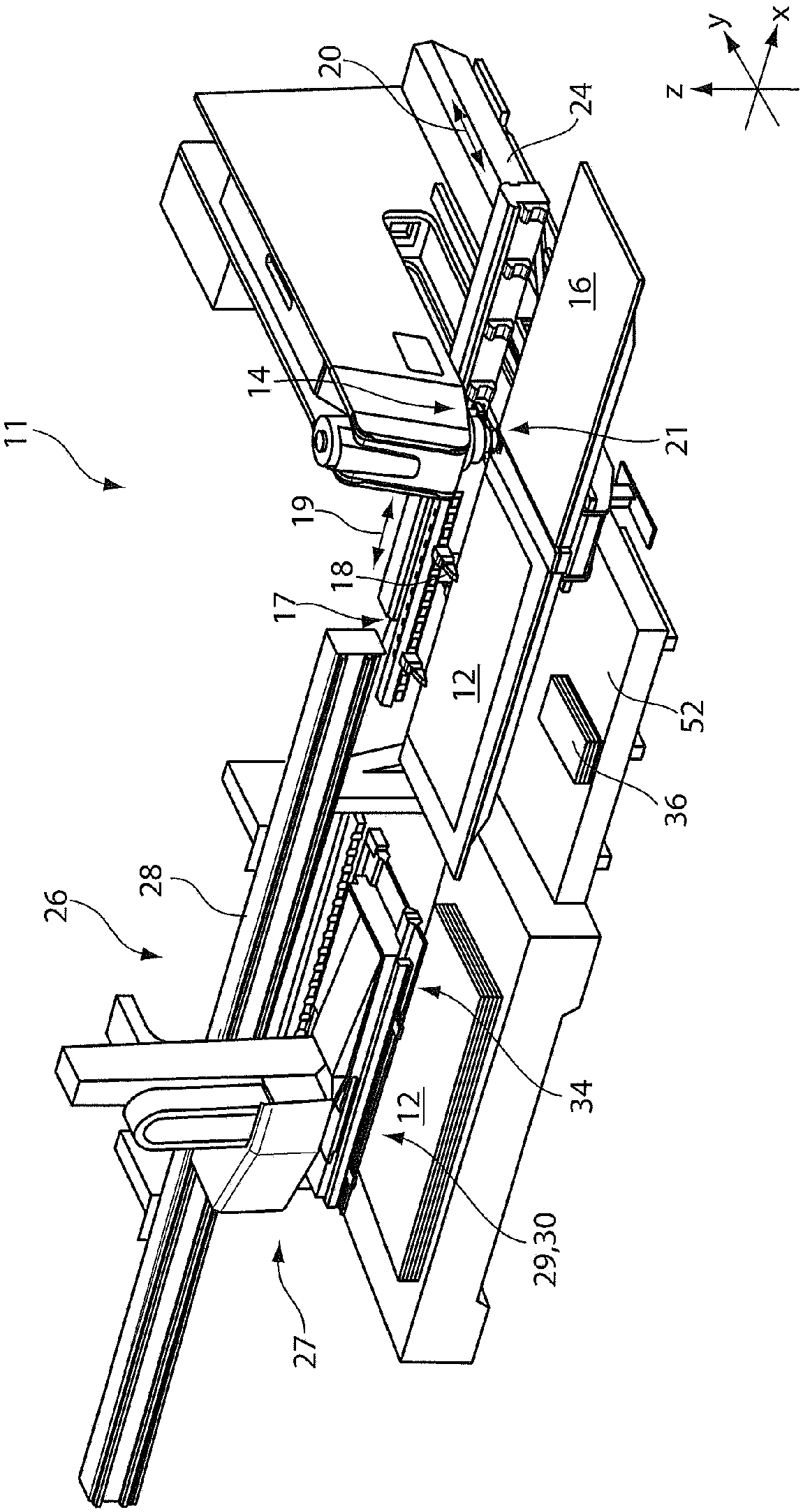

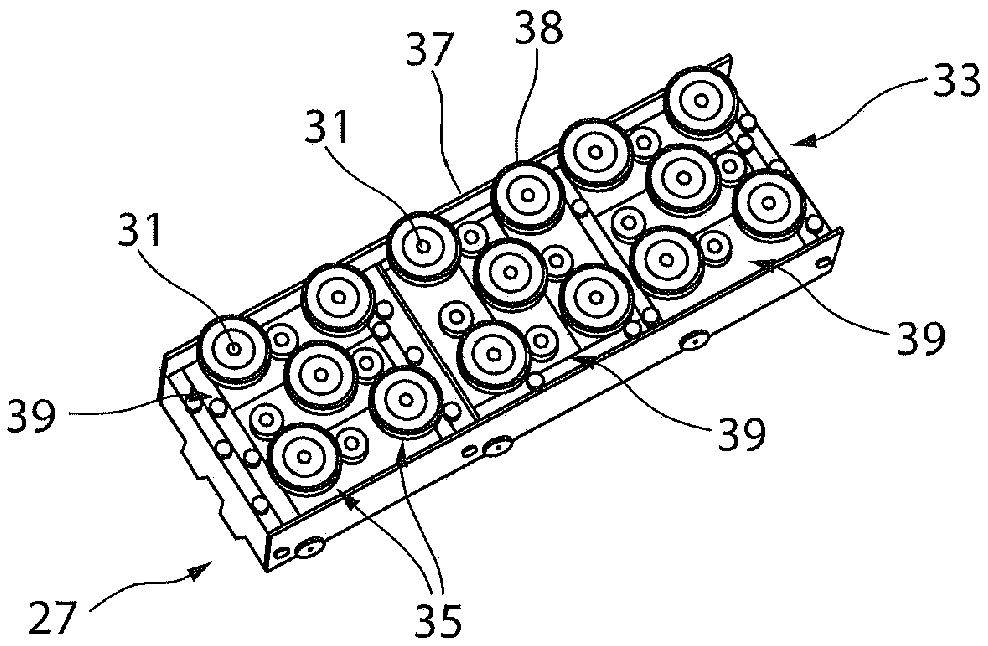

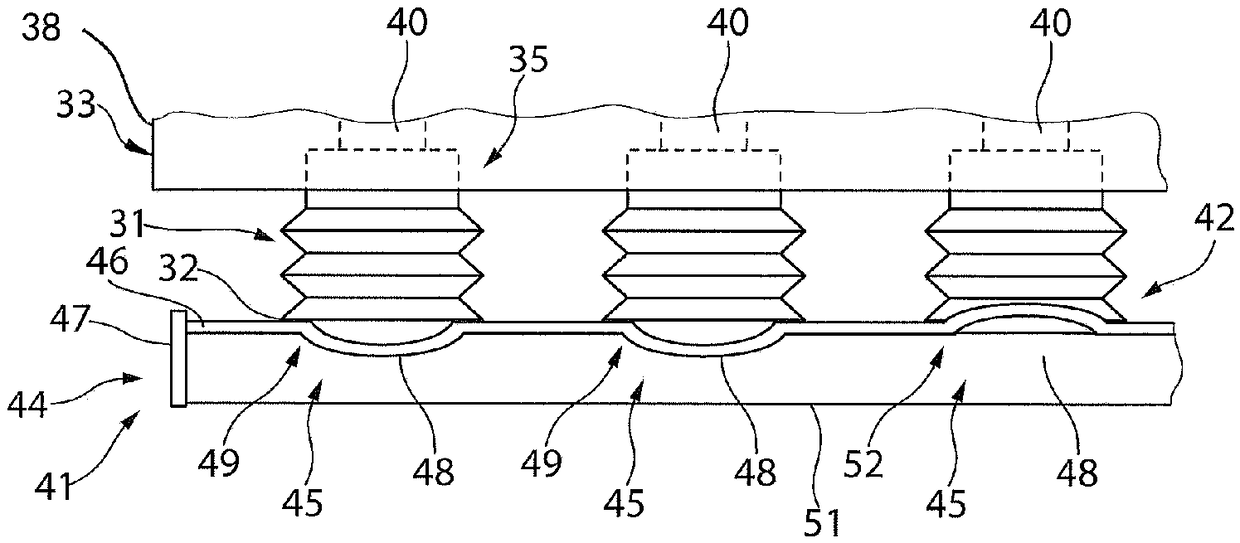

[0041] exist figure 1 A processing machine 11 is shown in three-dimensional form in the center, which is designed, for example, as a punching machine. For the separate processing of a plate-shaped workpiece 12 , for example in the form of a sheet metal, a preferably stationary processing device 21 is provided which has a punch 14 and a die, not shown in detail. Alternatively, a laser stamping machine can also be used, in which a laser processing head is arranged adjacent to the punch 14 . The workpiece 12 to be processed rests on the workpiece carrier 16 during workpiece processing. The workpiece 12 is held during machining by means of a holding device 17, preferably comprising a gripper 18, and can be moved relative to the punch 14 along the X axis of the workpiece plane (X / Y plane) by means of a conventional linear drive 19 indicated by an arrow. direction, the workpiece 12 can be moved along the Y direction of the workpiece plane in that the workpiece carrier 16 is relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com