A kind of glazed brick with crackle effect and its preparation process

A preparation process and technology for glazed tiles, applied in the field of architectural ceramics, can solve the problems of difficulty in adjusting the thickness and transition of crack lines, rigid transition changes of crack lines, and insufficiently delicate and realistic crack effects, so as to achieve easy control of the thickness of cracks and smooth edges of cracks. , the effect of easy control of crack width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

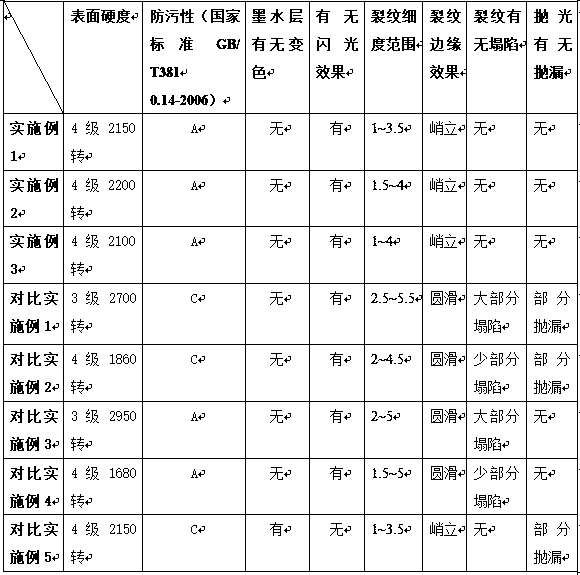

Examples

Embodiment 1

[0030] Embodiment 1-a kind of preparation technology of the glazed tile with crackle effect, comprises the steps:

[0031] (1) After drying and surface cleaning, the ceramic tile adobe is sprayed with water and then applied with a high-temperature surface glaze to form a high-temperature surface glaze layer; the high-temperature surface glaze contains 55% by weight of silicon dioxide, and the silicon-aluminum ratio is The ratio range is 2.3, the specific gravity of the high-temperature surface glaze is 1.9, its initial melting point temperature is 1060°C, and its glaze amount is 110±2g / 330×660 measuring pan;

[0032] (2) Control the temperature of the adobe within the range of 45-55°C, and use System eight-channel ceramic inkjet printer to print decorative ink on the surface glaze layer according to the required pattern design to form a decorative pattern layer;

[0033] (3) Control the temperature of the adobe within the range of 45~55°C, and use the large ink nozzle of the i...

Embodiment 2

[0036] Embodiment 2-a kind of preparation technology of the glazed tile with crackle effect, comprises the steps:

[0037] (1) After drying and surface cleaning, the ceramic tile adobe is sprayed with water and then applied with a high-temperature surface glaze to form a high-temperature surface glaze layer; the high-temperature surface glaze contains 60% by weight of silicon dioxide, and the silicon-aluminum ratio is The ratio range is 2.4, the specific gravity of the high-temperature surface glaze is 1.85, its initial melting point temperature is 1150°C, and its glaze amount is 110±2g / 330×660 measuring pan;

[0038] (2) Control the temperature of the adobe within the range of 45-55°C, and use System eight-channel ceramic inkjet printer to print decorative ink on the surface glaze layer according to the required pattern design to form a decorative pattern layer;

[0039] (3) Control the temperature of the adobe within the range of 45~55°C, and use a large-volume nozzle of an ...

Embodiment 3

[0042] Embodiment 3-a kind of preparation technology of the glazed tile with crackle effect, comprises the steps:

[0043] (1) After drying and surface cleaning, the ceramic tile adobe is sprayed with water and then applied with a high-temperature surface glaze to form a high-temperature surface glaze layer; the high-temperature surface glaze contains 65% by weight of silicon dioxide 1, and the ratio of silicon to aluminum The ratio range is 2.5, the specific gravity of the high-temperature surface glaze is 1.8, its initial melting point temperature is 1080°C, and its glaze amount is 110±2g / 330×660 measuring pan;

[0044] (2) Control the temperature of the adobe within the range of 45-55°C, and use System eight-channel ceramic inkjet printer to print decorative ink on the surface glaze layer according to the required pattern design to form a decorative pattern layer;

[0045] (3) Control the temperature of the adobe within the range of 45~55°C, and use the inkjet printer with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com