Production method for processing steamed potato bread by using fresh potatoes

A production method and potato technology, which is applied in the field of food processing, can solve the problems of long production cycle of potato steamed bread and potato steamed bread, and achieve the effects of good taste, cost saving and shortened production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

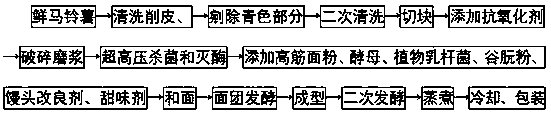

Method used

Image

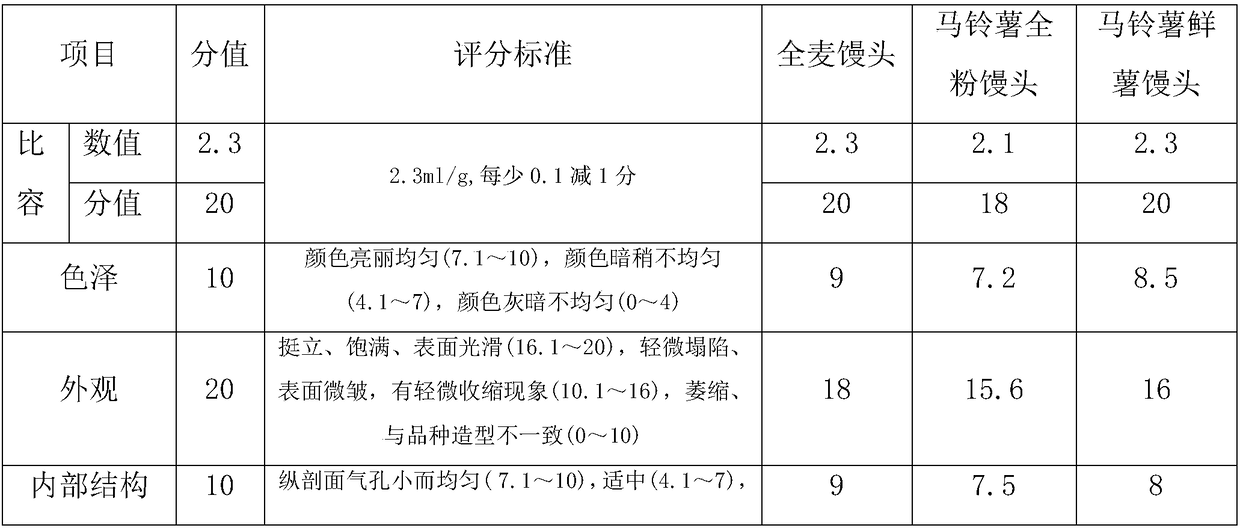

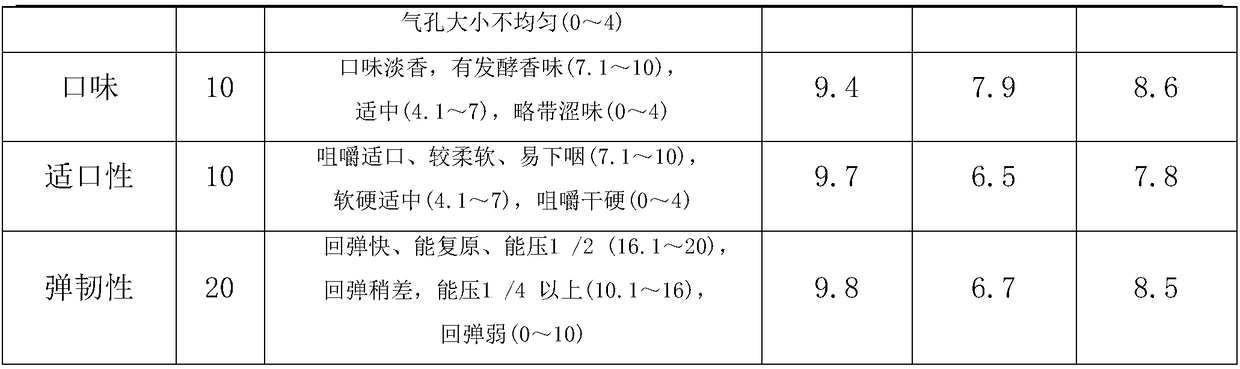

Examples

Embodiment 1

[0035] A kind of production method that adopts fresh potato to make potato steamed bread, comprises the steps:

[0036] S1: After washing and peeling fresh potatoes with 40 parts by weight, they are washed twice, and then cut into pieces, and the potato pieces and 0.05 parts by weight of D-isoascorbic acid Sodium is put into the high-speed mixer, and it is beaten to obtain fresh potato pulp;

[0037] S2: Put the fresh potato pulp obtained in S1 into an autoclave at normal temperature for ultra-high pressure sterilization and enzyme inactivation to obtain cooked potato pulp. The ultra-high pressure is 400 MPa and the time is 30s;

[0038] S3: Put 50 parts by weight of high-gluten flour, 0.5 part of yeast, 0.1 part of plantaractobacillus, 0.1 part of steamed bread quality improver, 1 part of gluten and 0.01 part of sweetener into the notification Mix evenly in a blender to obtain a mixed powder. The sweetener is composed of aspartame and sodium cyclamate, and the sweetener is c...

Embodiment 2

[0046] A kind of production method that adopts fresh potato to make potato steamed bread, comprises the steps:

[0047] S1: After washing and peeling fresh potatoes with 50 parts by weight, they are washed twice, and then cut into pieces, and the potato pieces and 0.08 parts by weight of D-isoascorbic acid Sodium is put into the high-speed mixer, and it is beaten to obtain fresh potato pulp;

[0048] S2: Put the fresh potato pulp obtained in S1 into an autoclave at normal temperature for ultra-high pressure sterilization and enzyme inactivation to obtain cooked potato pulp. The ultra-high pressure is 600 MPa and the time is 60 s;

[0049] S3: Put 40 parts by weight of high-gluten flour, 0.7 part of yeast, 0.3 part of plantaractobacillus, 0.3 part of steamed bread quality improver, 1.5 part of gluten and 0.01 part of sweetener into the notification Mix evenly in a blender to obtain a mixed powder. The sweetener is composed of aspartame and sodium cyclamate, and the sweetener i...

Embodiment 3

[0057] A kind of production method that adopts fresh potato to make potato steamed bread, comprises the steps:

[0058] S1: After washing and peeling fresh potatoes with 45 parts by weight, they are washed twice, and then cut into pieces, and the potato pieces and 0.06 parts by weight of D-isoascorbic acid Sodium is put into the high-speed mixer, and it is beaten to obtain fresh potato pulp;

[0059] S2: Put the fresh potato pulp obtained in S1 into an autoclave at room temperature for ultra-high pressure sterilization and enzyme inactivation to obtain cooked potato pulp. The ultra-high pressure is 500 MPa and the time is 45 s;

[0060] S3: Put 45 parts by weight of high-gluten flour, 0.6 part of yeast, 0.2 part of plantaractobacillus, 0.2 part of steamed bread quality improver, 1.3 part of gluten and 0.01 part of sweetener into the notification Mix evenly in a blender to obtain a mixed powder. The sweetener is composed of aspartame and sodium cyclamate, and the sweetener is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com