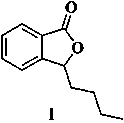

Preparation method of butylphthalide and pharmaceutical intermediate thereof

A technology of intermediates and drugs, which is applied in the field of medicinal chemistry, can solve problems such as unsuitable for large-scale industrial production, unavailable raw materials, and high toxicity of cyanide ketones, so as to facilitate large-scale industrial production, avoid the use of Grignard reagents, The effect of reducing production energy consumption and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation of embodiment 1 2-(methoxycarbonyl) benzoic acid

[0041] Add 500g of phthalic anhydride to a 3L reaction flask, add 2L of methanol to the system, raise the temperature of the system to 60-80°C until the phthalic anhydride disappears, concentrate under reduced pressure to remove methanol, and obtain a wet product at 50°C Vacuum drying for 4-6 hours gave 588 g of 2-(methoxycarbonyl)benzoic acid, with a yield of 96.7%.

Embodiment 2

[0042] Example 2 Preparation of 2-(ethoxycarbonyl)benzoic acid

[0043] Add 500g of phthalic anhydride to a 3L reaction flask, add 2L of ethanol to the system, raise the temperature of the system to 60-80°C until the phthalic anhydride disappears, concentrate under reduced pressure to remove ethanol, and obtain a wet product at 50°C Vacuum drying for 4-6 hours gave 596 g of 2-(ethoxycarbonyl)benzoic acid, with a yield of 91.0%.

Embodiment 3

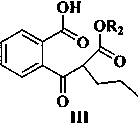

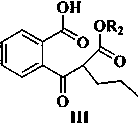

[0044] Example 3 2-[(2-Methoxycarbonyl)pentanoyl]benzoic acid

[0045] Add 428g of sodium hydride into a 5L reaction flask, add 3.1L of N,N-dimethylformamide, 311g of methyl valerate and 580g of 2-(methoxycarbonyl)benzoic acid to the system at 0-10°C, The temperature of the system rises to 90-100°C, react at this temperature for 4-6 hours, stop heating, lower the system to room temperature, add 4L of purified water and stir until the system is dissolved, adjust the pH of the system to 2-3 with concentrated hydrochloric acid, ethyl acetate After ester extraction, the organic phase was separated, washed with saturated brine, dried over anhydrous sodium sulfate, and concentrated in vacuo to obtain 646 g of 2-[(2-methoxycarbonyl)pentanoyl]benzoic acid, with a yield of 91.2%. Purity 95.6% (HPLC method);

[0046] 1 HNMR (400MHz, CDCl 3 )7.84(t, 1H), 7.72(d, 1H), 7.63−7.52(m, 2H), 3.78(s, 3H, OCH 3 ), 2.93 (dd, 1H), 2.35–1.73 (m, 2H), 1.34–1.25 (m, 4H), 0.90 (t, 3H). LC-MS for C...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap