Inhaul cable with sealing structure rain covers and manufacturing method thereof

A sealing structure and rainproof cover technology, which is applied in the direction of cable-stayed bridges, bridge parts, bridge forms, etc., can solve problems such as steel wire corrosion, multiple installation steps, and sheath failure, and achieve improved durability, effective sealing, and simple installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

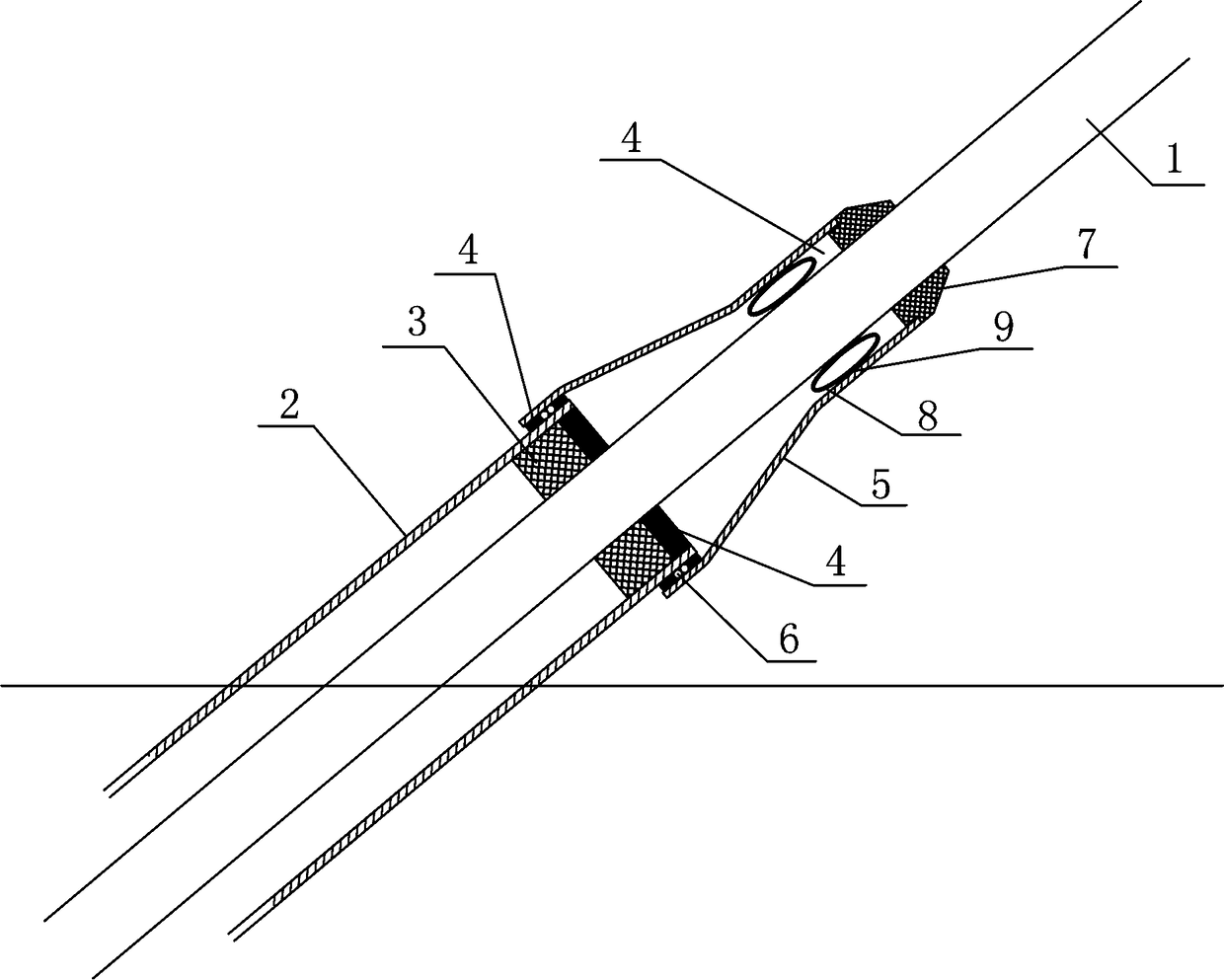

[0031] A cable with a rainproof cover of a sealed structure, including a cable stock body 1, a cable guide 2, a shock absorber 3, a sealant 4, a rainproof cover 5, a sealing ring 6, an end cover 7 and an air bag 8, such as figure 1 As shown, the specific structure is:

[0032] The cable stock body 1 is made of steel wire, the cable guide 2 is set outside the cable stock body 1, and the cable stock body 1 is also hooped with two shock absorbers 3, and each shock absorber 3 is respectively arranged on an end surface of the cable guide 2 Inside, the outer end surface of the shock absorber 3 is lower than the end surface of the cable guide 2, the shock absorber 3 is arranged between the cable strand body 1 and the cable guide 2, the outer surface of the shock absorber 3 is attached to the inner surface of the cable guide 2, The sealant 4 is applied on the outer end surface of the shock absorber 3 until the sealant 4 is flush with the end surface of the cable guide 2;

[0033] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com